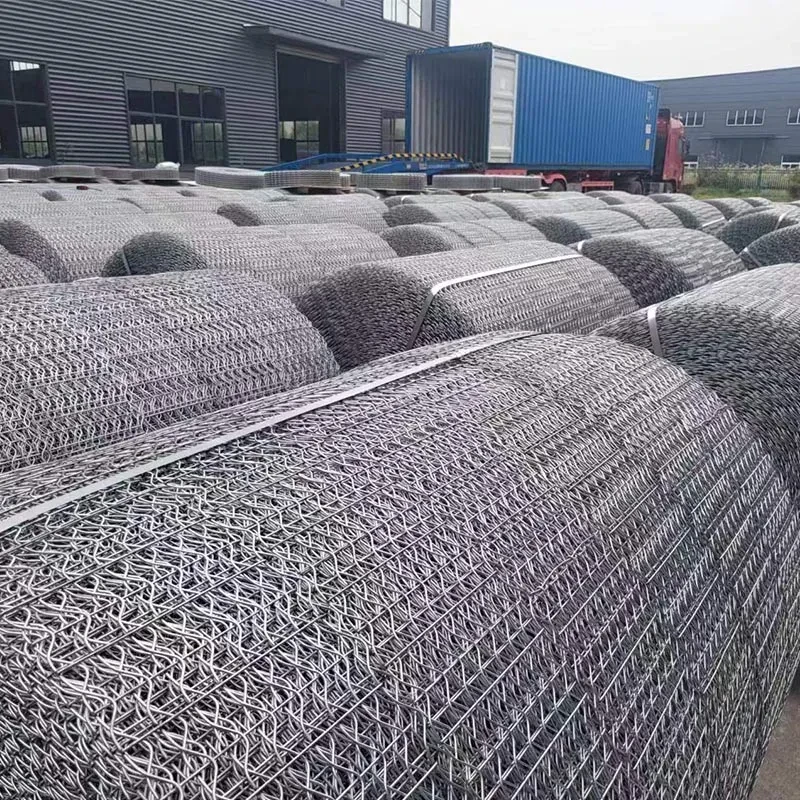

Offshore Pipeline Counterweight Welded Wire Mesh

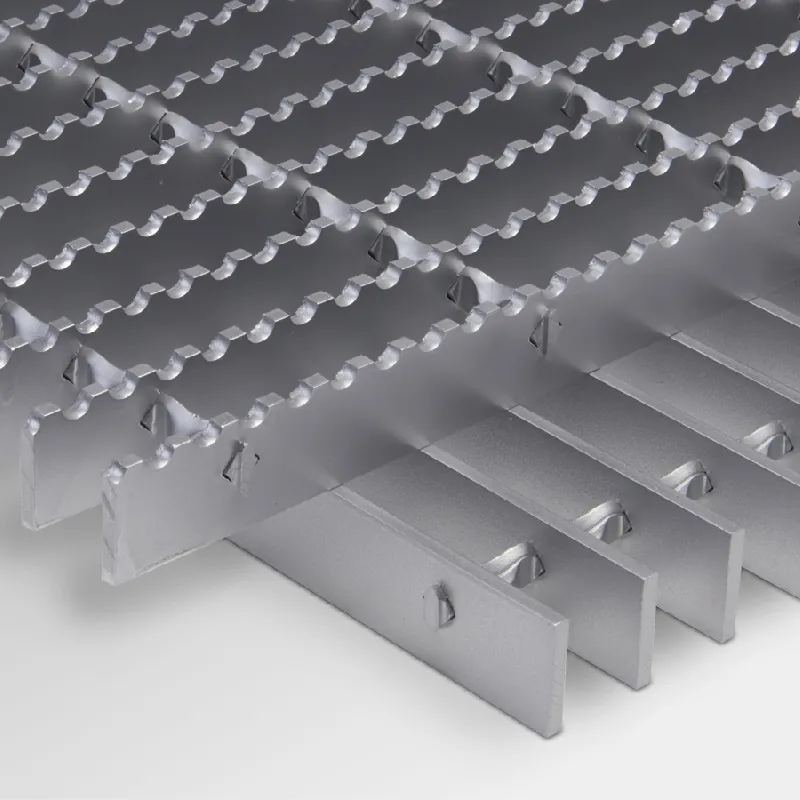

Offshore pipeline counterweight welded wire mesh is also called concrete weight coating mesh, Pipeline reinforced mesh, is a line wire crimped special welded mesh. It plays the role of reinforcement, counterweight and protection for offshore oil and gas pipelines.

Offshore pipeline counterweight welded wire mesh material is low carbon steel with galvanized coating. It can either be cold galvanized wire or hot dipped galvanized wire meeting to ASTM and the line wires are deeply crimped and then welded to form a wave structure, making it easy to be coated with concrete and then submerged in water or earth. It has excellent corrosion and rust resistant performance, preventing concrete weight coated pipeline from being damaged during installation and after it is in place.

High tensile strength

High tensile strengthPipeline reinforced mesh is made of high-strength steel wires that can withstand the stress and pressure of pipeline construction.

Anti-corrosion, anti-rust

concrete weight coating mesh can be easily installed around the pipeline, providing a quick and efficient solution for strengthening the pipeline.

Enhanced Structural Integrity

Enhanced Structural IntegrityWith the concrete weight coating acting as a protective layer, pipes exhibit enhanced structural integrity, effectively preventing cracks, leaks, and other structural issues that may compromise the pipeline's performance.

Cost-effective

Cost-effectiveBy choosing our concrete weight coating pipes, you make a wise investment in long-term cost savings. The extended lifespan, reduced maintenance needs, and enhanced durability of our pipes translate into significant cost savings over their operational lifetime.

Durable and long service life

Durable and long service lifePipeline reinforced mesh is designed to withstand harsh environmental conditions, including extreme temperatures and weather conditions.

Good appearance

Good appearanceThe appearance of Pipeline reinforced mesh is neat, regular, and bright. The mesh is tightly bound and firm. The solder joint is firm and convenient for transportation and stacking.

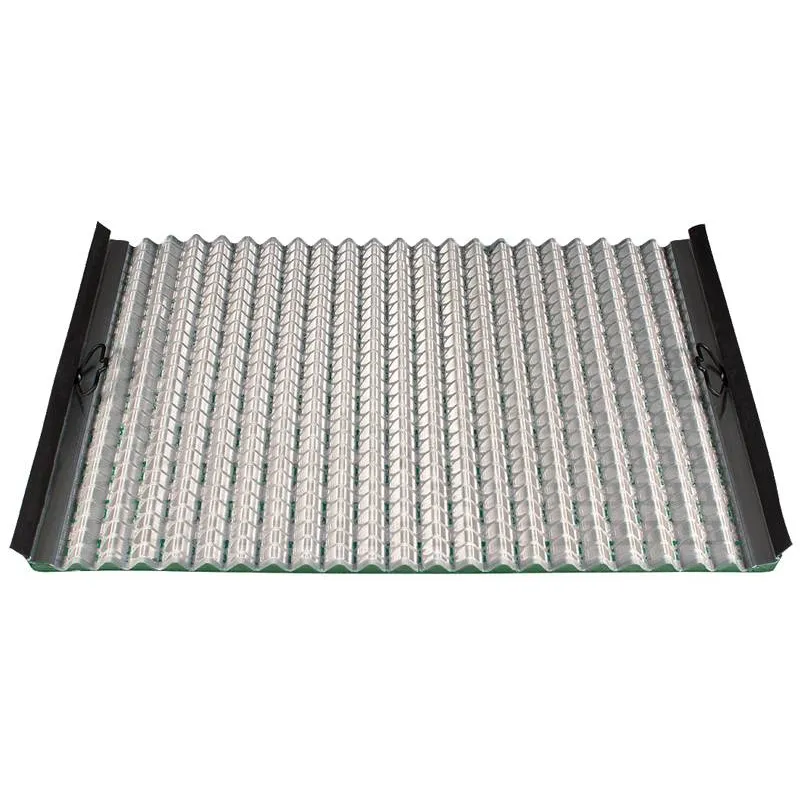

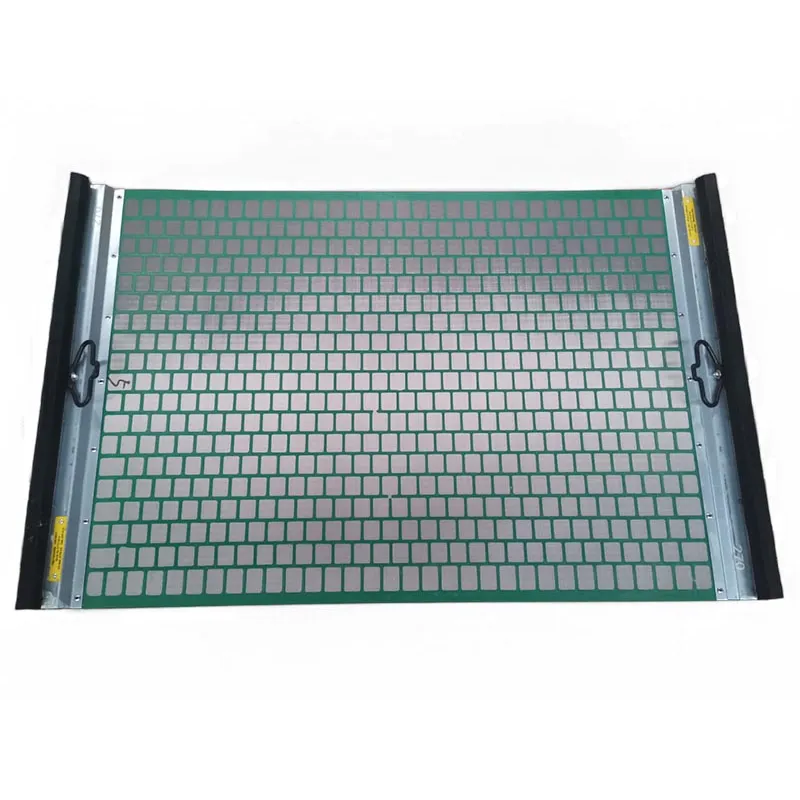

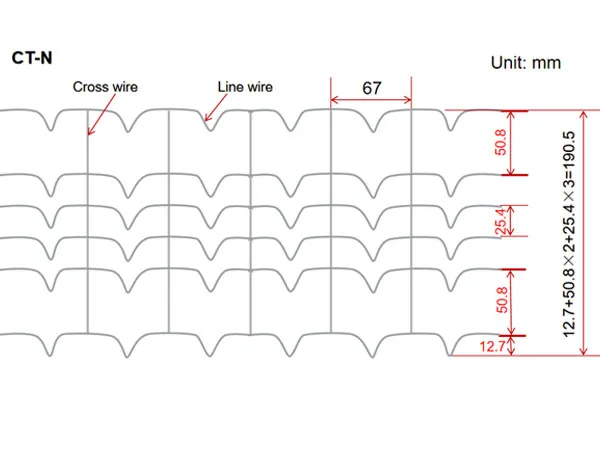

Pipeline Counterweight Mesh-structure

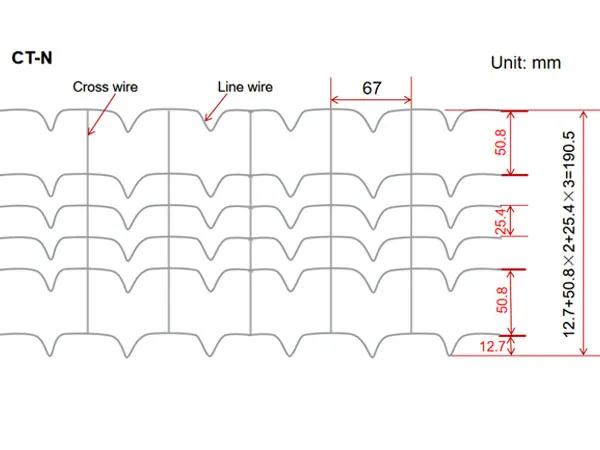

Pipeline Counterweight Mesh-structure

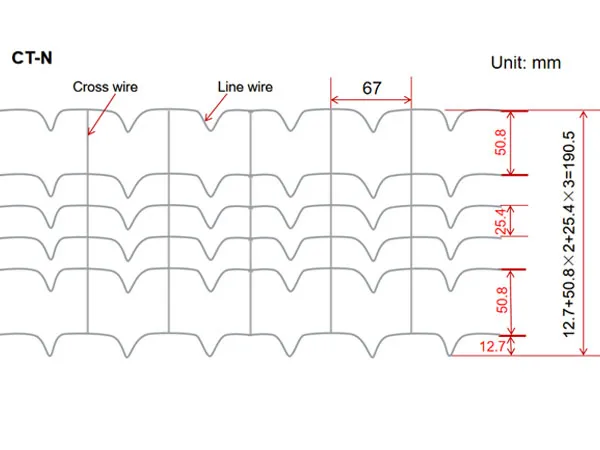

Pipeline Counterweight Mesh-structure

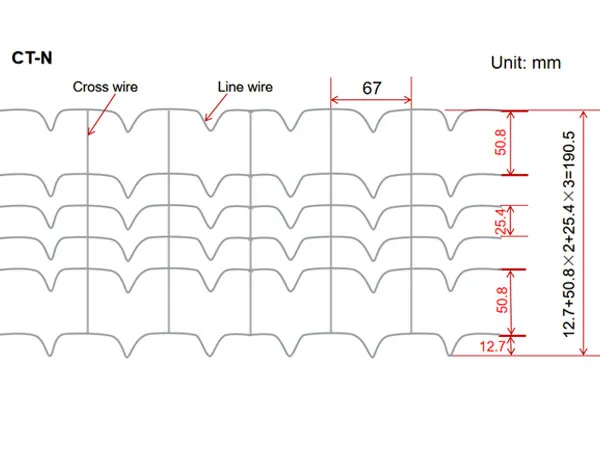

Pipeline Counterweight Mesh-structure

- Material: Q235 low carbon steel wire.

- Surface treatment: hot dipped galvanized.

- Amount of zinc:up to 300 g / m².

- Wire diameter: 1.6-2.85 mm.

- Roll length:110-295 m.

- Line wire quantity: 6, 8 or 10.

- Middle line wire pitch: 25.4 mm.

- Both sides line wire pitch: 25.4 mm or 50.8 mm.

- Cross wire pitch: 67 mm or 92.4 mm.

- Implementation standards: GB / T701, ASTM A641, GB / T1499.3, GB / T228, GB / T238, ASTM A370, ASTM A810, ASTM A185, ASTM A82, ASTM A1064.

- 4 types pipeline reinforced mesh: HF-N, HF-T, HF-L and HF-W.

|

Pipeline reinforced mesh specifications |

|||||||||

|

Item |

Line wire quantity |

line wire wire diameter |

Cross wire wire diameter |

Middle line wire pitch |

Both sides line wire pitch |

Cross wire pitch |

Mesh width |

Roll length |

Exposed Wire Edge |

|

HF-N |

6 |

2.3 mm 2.5 mm 2.6 mm 2.85 mm |

2 mm 2.05 mm

|

25.4 mm |

50.8 mm |

67 mm |

190.5mm |

110-295 m |

≤ 2.5 mm |

|

HF-T |

8 |

25.4 mm |

25.4 mm |

67 mm |

190.5mm |

≤ 2.5 mm |

|||

|

HF-L |

8 |

25.4 mm |

25.4 mm |

92.4 mm |

190.5mm |

≤ 2.5 mm |

|||

|

HF-W |

10 |

25.4 mm |

25.4 mm |

67 mm |

241.3 mm |

≤ 2.5 mm |

|||

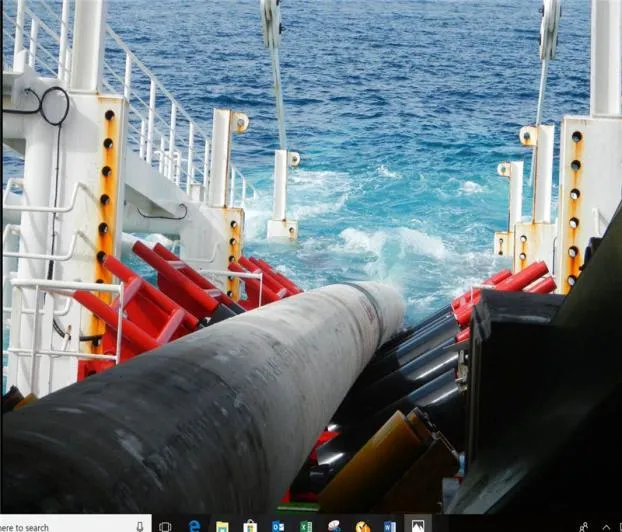

Pipeline reinforced mesh is commonly used in a variety of pipeline applications,including:

Subsea Gas&Oil Pipeline

Pipeline reinforced mesh is used to reinforce subsea oil and gas pipelines,providing additional strength and durability to the pipeline.

Everglades Gas Pipeline

The CWC mesh can be used to protect the everglades gas pipeline from external factors such as erosion,corrosion,or wildlife damage.

River Bottom Gas&Oil Pipeline

Pipeline reinforced mesh provides additional support and reinforcement to distribute the weight of the pipeline more evenly across the river or stream bed.This can help reduce the risk of damage to the river or stream bed.

Water and Wastewater Pipeline

This technique is highly effective in preventing corrosion in water distribution systems,sewage treatment plants,and desalination facilities.

Chemical Processing Pipeline

CWC lining with wire mesh safeguards pipelines in chemical plants,refineries,and petrochemical facilities,protecting them from aggressive chemicals and corrosive substances.

Mining and Ore Processing Pipeline

Steel pipes used in mining operations and ore processing plants can benefit from the exceptional corrosion resistance provided by CWC lining with wire mesh.

-

Pipeline Reinforced Mesh For Pipe

-

Pipeline Reinforced Mesh And Pipe Production

-

Offshore Pipeline Reinforced Mesh

-

Pipeline Reinforced Mesh Pipe Installation

-

Pipe With Pipeline Reinforced Mesh

-

Pipeline Reinforced Mesh Pipe Conveyor Rollers

-

Offshore Pipeline Reinforced Mesh Machinery

-

Pipeline Reinforced Mesh Gas Pipe