- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 02, 2025 00:55

Back to list

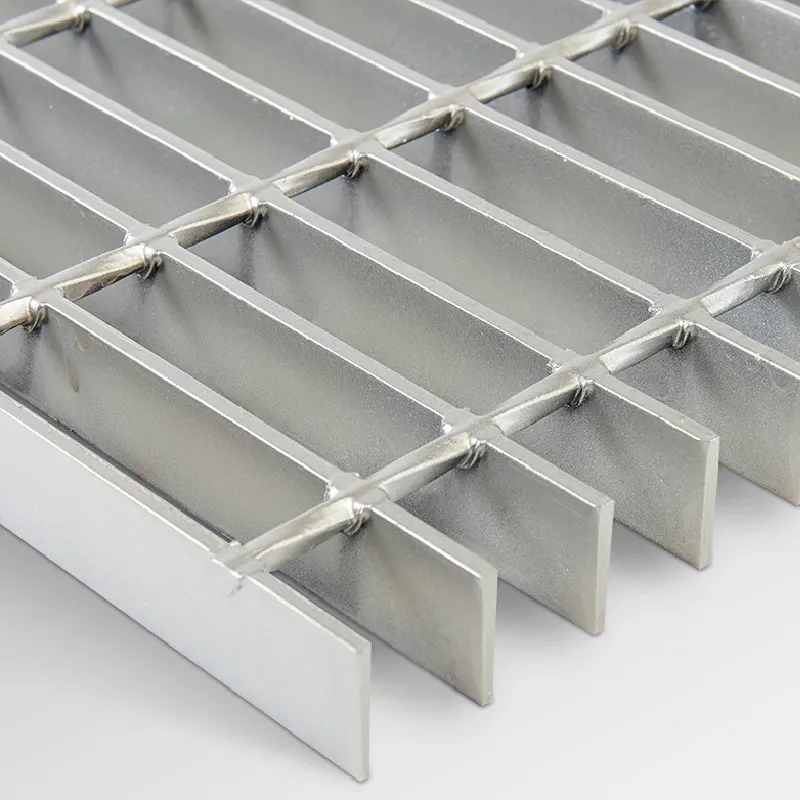

steel grating thickness

Steel grating thickness is an integral component in determining the efficacy and suitability of grating for various industrial applications. Reflecting on years of engagement with steel manufacturers and end-users, this article provides an in-depth examination of steel grating thickness and its implications for performance, safety, and cost-effectiveness.

Sustainability has become a significant focus in recent years, with the push towards more environmentally-friendly building practices. Thicker gratings are typically seen as less sustainable due to the increased material usage. However, incorporating recycled materials or using galvanization and coating techniques to enhance durability can offset these concerns. By working closely with suppliers who value sustainability, architects and engineers can strike a balance between structural needs and environmental responsibility. Furthermore, the choice of grating thickness has economic implications. Thicker gratings, while more expensive upfront, can lead to cost savings over time through enhanced durability and reduced need for replacements or repairs. For budget-conscious projects, understanding the trade-offs between immediate costs and long-term benefits is essential. Financial models that project maintenance costs over the lifespan of the grating can offer insightful data for making economical choices. Trust plays an essential role in the selection of steel grating products. Established manufacturers often provide detailed specifications and testing data to substantiate their claims about thickness and strength. Contracts should include clauses that address performance standards, ensuring that the delivered products meet the promised criteria. Relying on reputable manufacturers for steel grating supplies, therefore, becomes a wise investment for anyone concerned with product reliability and safety. For specialists and industry leaders recommending steel grating solutions, continuous education on the latest industry trends and technological advancements cannot be overstated. Acknowledging shifts in manufacturing processes, material sciences, and regulatory updates is vital for maintaining authority in the field. By keeping abreast of these developments, experts can provide trusted advice that reflects the latest knowledge and best practices. In conclusion, understanding the role of steel grating thickness combines experience, expertise, authoritativeness, and trustworthiness in various ways. From enhancing safety through load capacity considerations to balancing sustainability and cost, the thickness of grating informs many facets of product choice and application. Engaging deeply with these elements ensures not only a successful outcome but also provides customers with peace of mind regarding their investments in infrastructure and building materials.

Sustainability has become a significant focus in recent years, with the push towards more environmentally-friendly building practices. Thicker gratings are typically seen as less sustainable due to the increased material usage. However, incorporating recycled materials or using galvanization and coating techniques to enhance durability can offset these concerns. By working closely with suppliers who value sustainability, architects and engineers can strike a balance between structural needs and environmental responsibility. Furthermore, the choice of grating thickness has economic implications. Thicker gratings, while more expensive upfront, can lead to cost savings over time through enhanced durability and reduced need for replacements or repairs. For budget-conscious projects, understanding the trade-offs between immediate costs and long-term benefits is essential. Financial models that project maintenance costs over the lifespan of the grating can offer insightful data for making economical choices. Trust plays an essential role in the selection of steel grating products. Established manufacturers often provide detailed specifications and testing data to substantiate their claims about thickness and strength. Contracts should include clauses that address performance standards, ensuring that the delivered products meet the promised criteria. Relying on reputable manufacturers for steel grating supplies, therefore, becomes a wise investment for anyone concerned with product reliability and safety. For specialists and industry leaders recommending steel grating solutions, continuous education on the latest industry trends and technological advancements cannot be overstated. Acknowledging shifts in manufacturing processes, material sciences, and regulatory updates is vital for maintaining authority in the field. By keeping abreast of these developments, experts can provide trusted advice that reflects the latest knowledge and best practices. In conclusion, understanding the role of steel grating thickness combines experience, expertise, authoritativeness, and trustworthiness in various ways. From enhancing safety through load capacity considerations to balancing sustainability and cost, the thickness of grating informs many facets of product choice and application. Engaging deeply with these elements ensures not only a successful outcome but also provides customers with peace of mind regarding their investments in infrastructure and building materials.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024