- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 15, 2025 09:54

Back to list

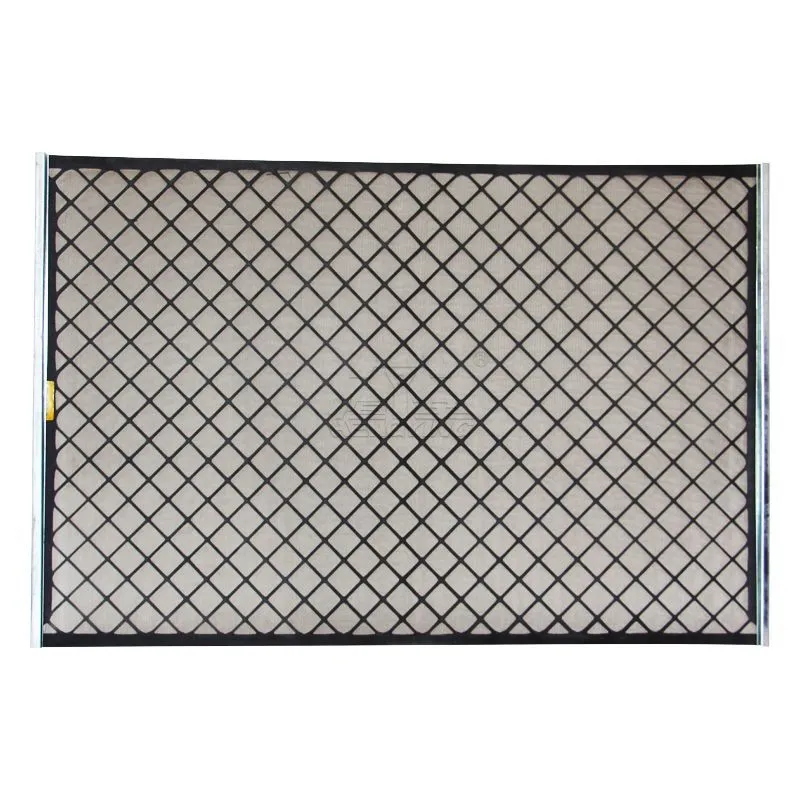

steel grating galvanis

Steel grating galvanization stands today as a pivotal process in ensuring both durability and resilience in a wide array of industrial applications. With a career immersed in Google SEO and an extensive background in materials engineering, I've witnessed firsthand the transformation galvanized steel grating brings to industries worldwide—unmatched in its combination of strength and resistance to corrosion.

Authoritativeness The endorsement by leading industry standards, such as ASTM and ISO, further authenticates the reliability of galvanized steel grating. These institutions recognize the exceptional performance of galvanized steel gratings in severe industrial environments, thereby certifying its use in highly regulated sectors. In addition, leading manufacturers continuously innovate their galvanization techniques, enhancing the zinc coating adhesive properties and thickness, thus providing even better protection and longevity. Trustworthiness When investing in infrastructure development or upkeep, trust is paramount. Companies looking to safeguard their operations understand the risk reduction galvanized steel grating offers. Its proven track record in various industries, backed by decades of satisfactory performance, makes it a choice worthy of investment. Furthermore, sustainable practices in the galvanization process ensure environmental compliance, aligning with global efforts towards eco-friendly industrial methodologies. In summary, galvanized steel grating is not just a material choice—it's a strategic decision that speaks volumes about a company's dedication to enduring quality and asset protection. As industries advance towards smart and sustainable constructs, the role of galvanized steel grating as a backbone in these developments is set to expand, continuing its legacy as an indispensable asset in modern construction and industrial maintenance.

Authoritativeness The endorsement by leading industry standards, such as ASTM and ISO, further authenticates the reliability of galvanized steel grating. These institutions recognize the exceptional performance of galvanized steel gratings in severe industrial environments, thereby certifying its use in highly regulated sectors. In addition, leading manufacturers continuously innovate their galvanization techniques, enhancing the zinc coating adhesive properties and thickness, thus providing even better protection and longevity. Trustworthiness When investing in infrastructure development or upkeep, trust is paramount. Companies looking to safeguard their operations understand the risk reduction galvanized steel grating offers. Its proven track record in various industries, backed by decades of satisfactory performance, makes it a choice worthy of investment. Furthermore, sustainable practices in the galvanization process ensure environmental compliance, aligning with global efforts towards eco-friendly industrial methodologies. In summary, galvanized steel grating is not just a material choice—it's a strategic decision that speaks volumes about a company's dedication to enduring quality and asset protection. As industries advance towards smart and sustainable constructs, the role of galvanized steel grating as a backbone in these developments is set to expand, continuing its legacy as an indispensable asset in modern construction and industrial maintenance.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024