- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 15, 2025 09:53

Back to list

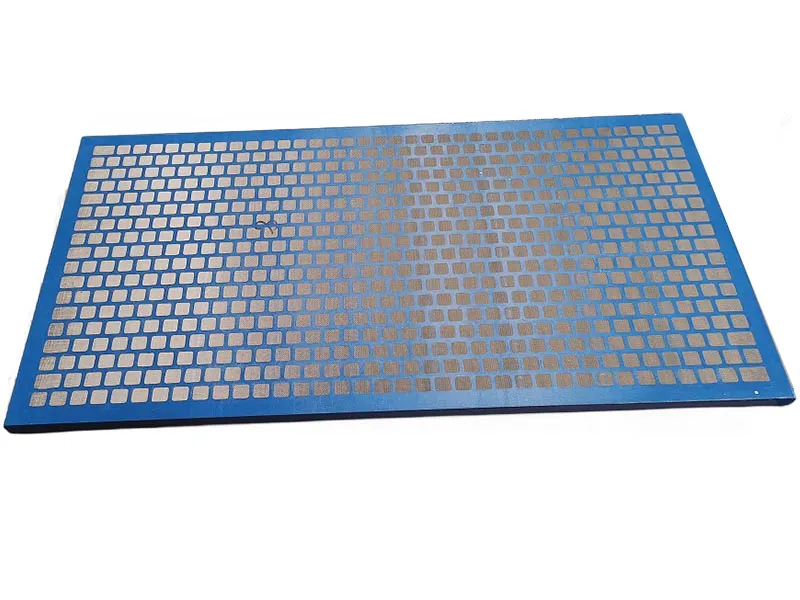

open steel grating

Open steel grating has fundamentally transformed how industries approach flooring solutions in various industrial applications. As a seasoned expert in industrial products, it's essential to understand both the technical nuances and practical advantages these gratings deliver, thereby building a foundation of trustworthiness and authority.

Moreover, maintenance remains a critical aspect of open steel grating utilization. The ease with which these gratings can be cleaned or repaired directly correlates with operational downtime and cost-efficiency. Based on comprehensive expertise, minimizing downtime remains a top priority for businesses. Regular checks for weld integrity, surface condition, and proper installation can prevent unforeseen failures, fostering an environment of accountability and operational excellence. Authoritativeness in this field also requires acknowledging the value of customized solutions. With applications ranging from walkways and stair treads to platforms and trench covers, tailoring gratings to specific dimensional needs and load requirements promises enhanced performance. Collaborating with manufacturers who exhibit technical proficiency in customization ensures that the grating meets exact specifications while adhering to industry standards, reinforcing the trust placed by clients in such products. In conclusion, the widespread adoption of open steel grating across industries is no mere coincidence. It stems from a deep-seated recognition of the grating's unique properties—its open design, strength, and material versatility. By grounding decisions in experience, expertise, authoritativeness, and trustworthiness, businesses can optimize their facility operations, ensuring safety, reliability, and efficiency. When it comes to flooring solutions, open steel grating stands as a testament to intelligent engineering and practical design, offering a model of innovation within the industrial product landscape.

Moreover, maintenance remains a critical aspect of open steel grating utilization. The ease with which these gratings can be cleaned or repaired directly correlates with operational downtime and cost-efficiency. Based on comprehensive expertise, minimizing downtime remains a top priority for businesses. Regular checks for weld integrity, surface condition, and proper installation can prevent unforeseen failures, fostering an environment of accountability and operational excellence. Authoritativeness in this field also requires acknowledging the value of customized solutions. With applications ranging from walkways and stair treads to platforms and trench covers, tailoring gratings to specific dimensional needs and load requirements promises enhanced performance. Collaborating with manufacturers who exhibit technical proficiency in customization ensures that the grating meets exact specifications while adhering to industry standards, reinforcing the trust placed by clients in such products. In conclusion, the widespread adoption of open steel grating across industries is no mere coincidence. It stems from a deep-seated recognition of the grating's unique properties—its open design, strength, and material versatility. By grounding decisions in experience, expertise, authoritativeness, and trustworthiness, businesses can optimize their facility operations, ensuring safety, reliability, and efficiency. When it comes to flooring solutions, open steel grating stands as a testament to intelligent engineering and practical design, offering a model of innovation within the industrial product landscape.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024