- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 15, 2025 09:54

Back to list

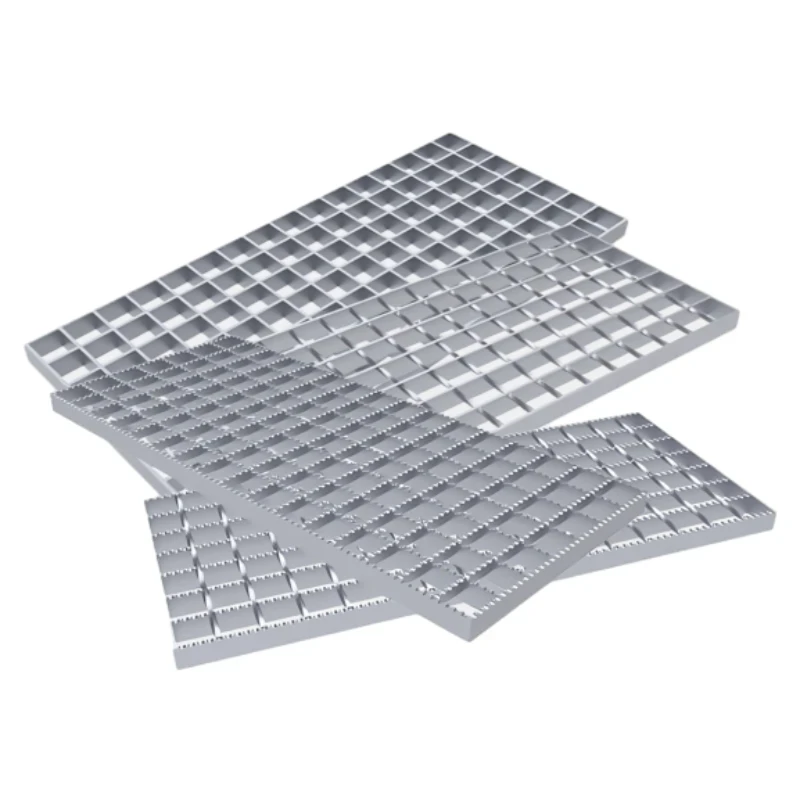

steel walkway grating

Steel grating panels are a foundational component in countless industrial and commercial applications, renowned for their strength, durability, and versatility. As someone who has spent over a decade in the field of industrial construction and design, I can affirm their indispensability in creating secure and efficient facilities.

Trust in the product is further fortified by advancements in manufacturing that permit customization to meet unique operational needs. Many reputable manufacturers offer bespoke solutions, crafting panels to exact specifications that include tailored dimensions, distinct surface treatments, and varied load capacities. In my practice, clients often benefit from these specialized solutions which enhance both the function and efficiency of their installations. Moreover, the sustainability of steel grating panels adds a layer of trustworthiness to their usage. With the global shift towards environmentally conscious construction methods, steel, as a 100% recyclable material, represents a sustainable option in infrastructure development. This characteristic supports long-term environmental goals while maintaining the rigorous performance standards required in demanding applications. In conclusion, steel grating panels are more than just a construction material; they are a critical component designed to withstand the most demanding conditions while offering unmatched durability, safety, and customization. The confidence in their use is grounded not just in their physical properties, but also in the industry standards and customization possibilities that empower them to meet and overcome diverse infrastructure challenges efficiently. My extensive experience with these panels convinces me that they continue to be an indispensable resource in achieving robust, safe, and future-oriented industrial designs.

Trust in the product is further fortified by advancements in manufacturing that permit customization to meet unique operational needs. Many reputable manufacturers offer bespoke solutions, crafting panels to exact specifications that include tailored dimensions, distinct surface treatments, and varied load capacities. In my practice, clients often benefit from these specialized solutions which enhance both the function and efficiency of their installations. Moreover, the sustainability of steel grating panels adds a layer of trustworthiness to their usage. With the global shift towards environmentally conscious construction methods, steel, as a 100% recyclable material, represents a sustainable option in infrastructure development. This characteristic supports long-term environmental goals while maintaining the rigorous performance standards required in demanding applications. In conclusion, steel grating panels are more than just a construction material; they are a critical component designed to withstand the most demanding conditions while offering unmatched durability, safety, and customization. The confidence in their use is grounded not just in their physical properties, but also in the industry standards and customization possibilities that empower them to meet and overcome diverse infrastructure challenges efficiently. My extensive experience with these panels convinces me that they continue to be an indispensable resource in achieving robust, safe, and future-oriented industrial designs.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024