- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 08, 2025 07:00

Back to list

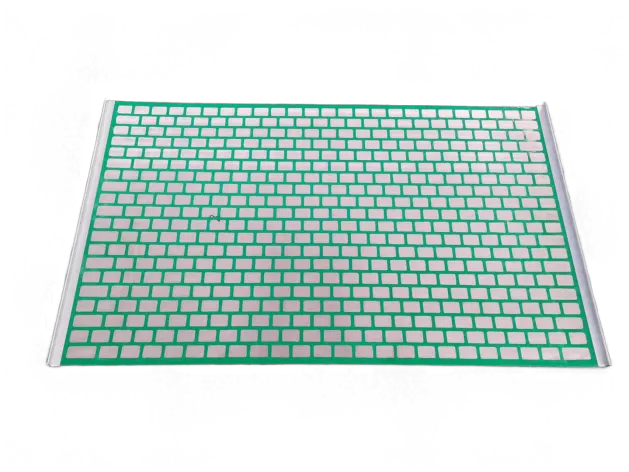

Steel Grating

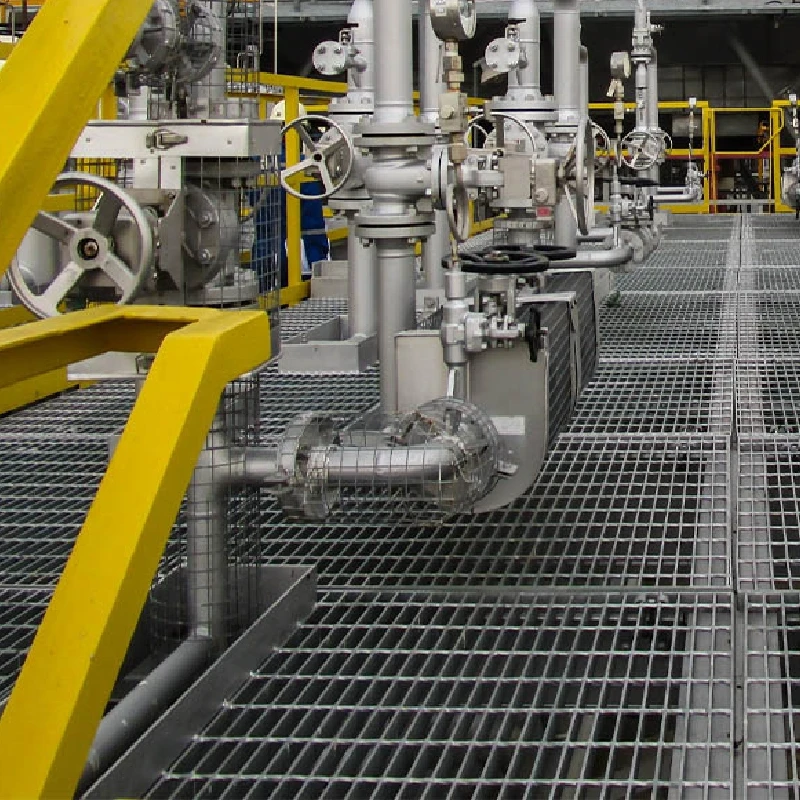

When it comes to superior construction and industrial applications, grating galvanized emerges as a top choice for many experts in the field due to its durability, cost-effectiveness, and versatile applications. Unlike other materials, galvanized grating is renowned for its robust resistance to corrosion, ensuring that structures remain safe and operational for decades. This article delves deep into the qualities that make galvanized grating an ideal choice and shares real-world applications, technical expertise, authoritative insights, and trustworthy evaluations on its use.

Authoritative bodies within the construction industry, such as the American Galvanizers Association, regularly publish studies underscoring the performance benefits of galvanized materials. These organizations advocate for the use of galvanized grating, especially in sustainable building designs. Testimonials from these bodies can further assure stakeholders of the reliability and integrity of this material. Furthermore, studies show that the reduced carbon footprint of galvanized materials contributes positively to environmental conservation efforts, aligning with global sustainability goals. Trustworthiness is a critical factor when selecting materials for construction projects. It's not just about durability but also about assured compliance with health and safety regulations. Galvanized grating, with its proven track record in corrosion resistance, provides peace of mind to stakeholders concerned about potential failures in corrosive environments. Trust is reinforced by the warranty support typically provided by manufacturers, ensuring that end-users are protected against manufacturing defects. In conclusion, galvanized grating stands as a paragon of efficiency and reliability in the material world. It has earned its reputation through practical application, expert endorsements, recognition by authoritative entities, and sustained performance over time. Whether the need is for a new pedestrian bridge, an industrial plant catwalk, or any structure requiring robust support, galvanized grating offers a cost-effective, sustainable, and dependable solution. As industries continue to evolve, the demand for materials that offer long-lasting resilience and trustworthy performance will only grow, with galvanized grating leading the charge. Thus, for stakeholders invested in infrastructure development, galvanized grating presents not merely an option, but a forward-looking choice built on solid foundations of trust and expert validation.

Authoritative bodies within the construction industry, such as the American Galvanizers Association, regularly publish studies underscoring the performance benefits of galvanized materials. These organizations advocate for the use of galvanized grating, especially in sustainable building designs. Testimonials from these bodies can further assure stakeholders of the reliability and integrity of this material. Furthermore, studies show that the reduced carbon footprint of galvanized materials contributes positively to environmental conservation efforts, aligning with global sustainability goals. Trustworthiness is a critical factor when selecting materials for construction projects. It's not just about durability but also about assured compliance with health and safety regulations. Galvanized grating, with its proven track record in corrosion resistance, provides peace of mind to stakeholders concerned about potential failures in corrosive environments. Trust is reinforced by the warranty support typically provided by manufacturers, ensuring that end-users are protected against manufacturing defects. In conclusion, galvanized grating stands as a paragon of efficiency and reliability in the material world. It has earned its reputation through practical application, expert endorsements, recognition by authoritative entities, and sustained performance over time. Whether the need is for a new pedestrian bridge, an industrial plant catwalk, or any structure requiring robust support, galvanized grating offers a cost-effective, sustainable, and dependable solution. As industries continue to evolve, the demand for materials that offer long-lasting resilience and trustworthy performance will only grow, with galvanized grating leading the charge. Thus, for stakeholders invested in infrastructure development, galvanized grating presents not merely an option, but a forward-looking choice built on solid foundations of trust and expert validation.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024