- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 08, 2025 06:36

Back to list

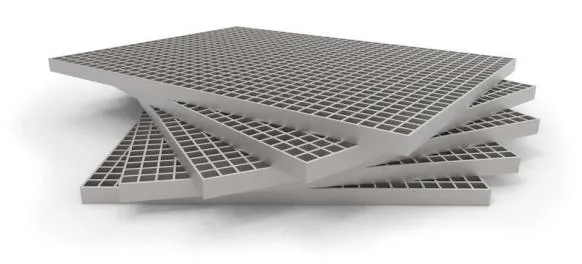

Steel Grating

The importance of metal walking grates in industrial and commercial spaces cannot be overstated. They combine practicality, safety, and durability in settings where these factors are critical. With years of experience in the field, I've encountered various scenarios where metal walking grates proved indispensable, making them a subject worth exploring for both novices and seasoned professionals alike.

Recent advancements in technology have allowed for the customization of metal walking grates. Today, manufacturers offer a variety of designs tailored to specific industry needs, such as serrated edges for increased slip resistance or custom load ratings. These improvements are crucial in settings with unique challenges and risks, offering businesses peace of mind knowing they're investing in products that protect their assets and personnel. Sustainability is another factor increasingly influencing the selection of metal walking grates. Companies are now mindful of choosing materials that are not only durable but also environmentally friendly. Metal grates can be manufactured from recycled materials and are, themselves, recyclable, making them a sustainable choice for eco-conscious organizations. Many manufacturers also adhere to strict environmental standards during production, further enhancing the appeal of metal grates from an ecological perspective. With over a decade in the industry, our team has built a reputation for delivering quality and reliability in metal walking grate solutions. Our commitment to excellence means we prioritize understanding each client’s unique requirements and delivering tailored products that meet the highest safety and quality standards. We work closely with architects, engineers, and construction professionals to ensure that every grate is not only fit for purpose but also contributes positively to the overall project objectives. In summary, metal walking grates are more than just functional floorings or covers; they are a vital component in maintaining safety, offering durability, and supporting structural integrity in numerous settings. As industries evolve, so too do the requirements for such materials, and staying informed about the latest developments is crucial for making the best choices for your specific needs. By leveraging industry knowledge and maintaining a focus on quality, sustainability, and innovation, we continue to empower businesses with the tools necessary to create safe and efficient environments. Whether you’re in search of grates for an industrial warehouse or an architectural project, understanding the options available and their respective benefits ensures you make a decision that enhances both safety and functionality.

Recent advancements in technology have allowed for the customization of metal walking grates. Today, manufacturers offer a variety of designs tailored to specific industry needs, such as serrated edges for increased slip resistance or custom load ratings. These improvements are crucial in settings with unique challenges and risks, offering businesses peace of mind knowing they're investing in products that protect their assets and personnel. Sustainability is another factor increasingly influencing the selection of metal walking grates. Companies are now mindful of choosing materials that are not only durable but also environmentally friendly. Metal grates can be manufactured from recycled materials and are, themselves, recyclable, making them a sustainable choice for eco-conscious organizations. Many manufacturers also adhere to strict environmental standards during production, further enhancing the appeal of metal grates from an ecological perspective. With over a decade in the industry, our team has built a reputation for delivering quality and reliability in metal walking grate solutions. Our commitment to excellence means we prioritize understanding each client’s unique requirements and delivering tailored products that meet the highest safety and quality standards. We work closely with architects, engineers, and construction professionals to ensure that every grate is not only fit for purpose but also contributes positively to the overall project objectives. In summary, metal walking grates are more than just functional floorings or covers; they are a vital component in maintaining safety, offering durability, and supporting structural integrity in numerous settings. As industries evolve, so too do the requirements for such materials, and staying informed about the latest developments is crucial for making the best choices for your specific needs. By leveraging industry knowledge and maintaining a focus on quality, sustainability, and innovation, we continue to empower businesses with the tools necessary to create safe and efficient environments. Whether you’re in search of grates for an industrial warehouse or an architectural project, understanding the options available and their respective benefits ensures you make a decision that enhances both safety and functionality.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024