- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 08, 2025 07:26

Back to list

Steel Grating

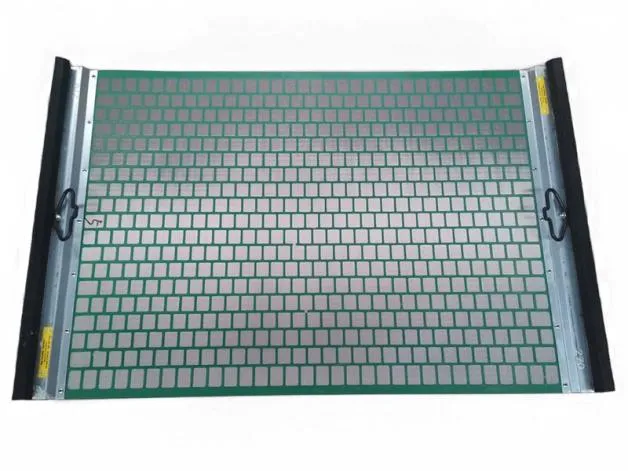

Large metal floor grates are often overlooked in the world of construction and interior design, yet they play a critical role in a range of environments. From industrial settings to architectural marvels, these floor grates are crucial for functionality, safety, and aesthetics. Drawing from years of experience and industry expertise, this article delves into the unique features, applications, and benefits of large metal floor grates, establishing their undeniable importance in various sectors.

Expert Insights Installation and Maintenance Installation of large metal floor grates calls for precision and expertise, ensuring they meet safety standards while aligning with the intended design vision. This often involves collaborating with engineers and architects to accurately integrate grates into the structural plan, considering factors such as load distribution, location, and traffic volume. Once installed, the longevity and functionality of metal floor grates are maintained through regular inspections and maintenance, which are pivotal for preventing potential hazards. Cleaning and checking for damage like warped sections or loose fittings ensure grates remain secure and effective. For industries where hygiene is paramount, stainless steel grates offer the added advantage of being easy to sanitize without degrading their surface. Building Trust Through Compliance and Certifications Incorporating compliant metal floor grates with relevant industry standards enhances the trustworthiness of any construction project. Trust is fortified through adherence to certifications such as ISO 9001 for quality management and specific safety or load-bearing specifications, depending on the region and application. Engaging manufacturers and suppliers who provide certified and tested products assures stakeholders of the project's integrity and quality. Embracing Innovation and Future Trends As technology advances, so does the innovation within the floor grate industry. Smart grates equipped with sensors for monitoring load and environmental conditions are emerging, offering new dimensions of efficiency and safety. Moreover, sustainable practices in manufacturing, such as using recycled materials and reducing waste, position metal floor grates as future-forward choices for eco-conscious projects. In conclusion, large metal floor grates are indispensable components that extend beyond mere functionality. They represent a convergence of design, safety, and sustainability, backed by industry expertise and innovative technology. Their versatile applications across diverse settings underline their value, setting the standard for quality and reliability in modern construction and design.

Expert Insights Installation and Maintenance Installation of large metal floor grates calls for precision and expertise, ensuring they meet safety standards while aligning with the intended design vision. This often involves collaborating with engineers and architects to accurately integrate grates into the structural plan, considering factors such as load distribution, location, and traffic volume. Once installed, the longevity and functionality of metal floor grates are maintained through regular inspections and maintenance, which are pivotal for preventing potential hazards. Cleaning and checking for damage like warped sections or loose fittings ensure grates remain secure and effective. For industries where hygiene is paramount, stainless steel grates offer the added advantage of being easy to sanitize without degrading their surface. Building Trust Through Compliance and Certifications Incorporating compliant metal floor grates with relevant industry standards enhances the trustworthiness of any construction project. Trust is fortified through adherence to certifications such as ISO 9001 for quality management and specific safety or load-bearing specifications, depending on the region and application. Engaging manufacturers and suppliers who provide certified and tested products assures stakeholders of the project's integrity and quality. Embracing Innovation and Future Trends As technology advances, so does the innovation within the floor grate industry. Smart grates equipped with sensors for monitoring load and environmental conditions are emerging, offering new dimensions of efficiency and safety. Moreover, sustainable practices in manufacturing, such as using recycled materials and reducing waste, position metal floor grates as future-forward choices for eco-conscious projects. In conclusion, large metal floor grates are indispensable components that extend beyond mere functionality. They represent a convergence of design, safety, and sustainability, backed by industry expertise and innovative technology. Their versatile applications across diverse settings underline their value, setting the standard for quality and reliability in modern construction and design.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024