- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 16, 2025 03:14

Back to list

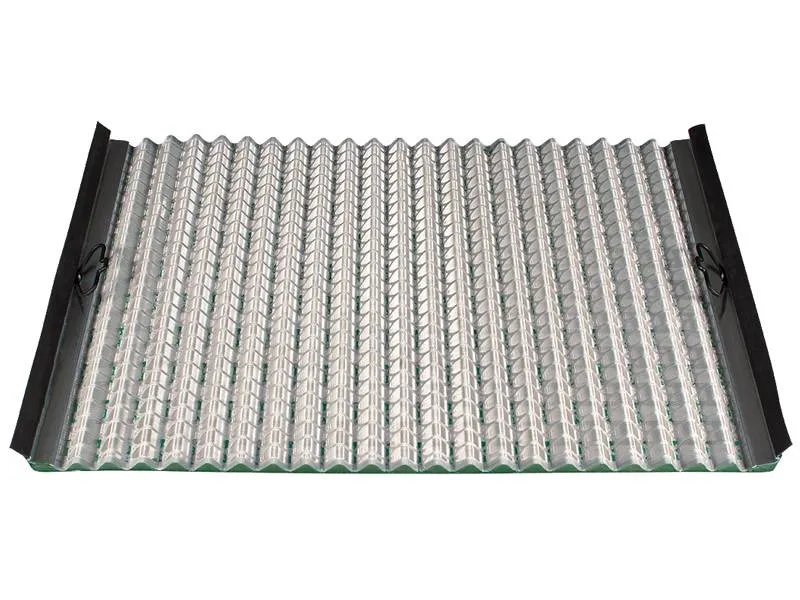

bar grating prices

Understanding the dynamics of bar grating prices involves a nuanced consideration of various market elements and technical specifications. Bar grating, a versatile industrial flooring solution, finds its application across different sectors such as manufacturing plants, pedestrian walkways, and offshore platforms due to its strength and durability. Having a thorough grasp of the key elements that influence bar grating prices can guide both purchasers and procurement specialists to make informed decisions.

Market forces, such as global economic conditions, also influence bar grating prices. The fluctuating costs of raw materials alongside tariffs and trade policies can dramatically affect the pricing landscape. For instance, changes in steel production costs or international trade tariffs might drive a swift rise or fall in pricing, necessitating buyers to maintain market vigilance and engage in strategic procurement. Furthermore, sourcing from reputable and authoritative manufacturers provides an added layer of reliability and trustworthiness. Established suppliers often offer insights and recommendations based on extensive industry experience, assisting in making choices that balance cost with performance. Engaging with manufacturers who provide transparent pricing structures and detailed product information can greatly enhance procurement outcomes. Prioritizing vendor credibility and price transparency ensures long-term asset viability. As the industry exhibits ever-evolving requirements and technological advancements, building a relationship with knowledgeable suppliers who can offer expert guidance on the latest trends and materials is invaluable. In conclusion, understanding the variables that influence bar grating prices enables stakeholders to strike a balance between cost efficiency and product effectiveness. By considering material choice, manufacturing methods, customization options, market conditions, and supplier credibility, decision-makers equip themselves to navigate the complexities of bar grating pricing adeptly, ensuring both economic and operational success.

Market forces, such as global economic conditions, also influence bar grating prices. The fluctuating costs of raw materials alongside tariffs and trade policies can dramatically affect the pricing landscape. For instance, changes in steel production costs or international trade tariffs might drive a swift rise or fall in pricing, necessitating buyers to maintain market vigilance and engage in strategic procurement. Furthermore, sourcing from reputable and authoritative manufacturers provides an added layer of reliability and trustworthiness. Established suppliers often offer insights and recommendations based on extensive industry experience, assisting in making choices that balance cost with performance. Engaging with manufacturers who provide transparent pricing structures and detailed product information can greatly enhance procurement outcomes. Prioritizing vendor credibility and price transparency ensures long-term asset viability. As the industry exhibits ever-evolving requirements and technological advancements, building a relationship with knowledgeable suppliers who can offer expert guidance on the latest trends and materials is invaluable. In conclusion, understanding the variables that influence bar grating prices enables stakeholders to strike a balance between cost efficiency and product effectiveness. By considering material choice, manufacturing methods, customization options, market conditions, and supplier credibility, decision-makers equip themselves to navigate the complexities of bar grating pricing adeptly, ensuring both economic and operational success.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024