- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 16, 2025 02:52

Back to list

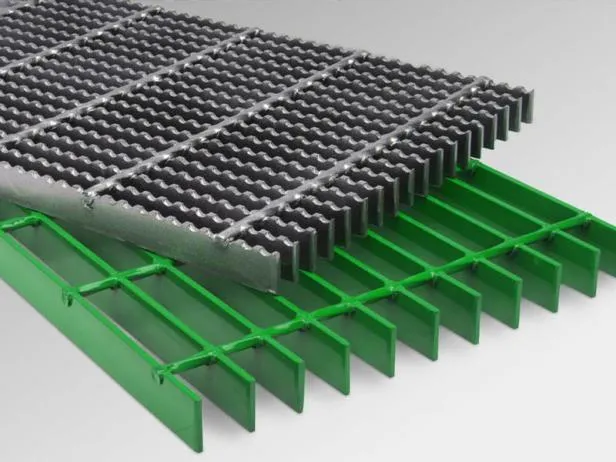

heavy duty steel grating price

Understanding the implications of grating prices is essential for businesses and consumers involved in industries that utilize grating systems. Grating, an assemblage of steel, aluminum, or other materials, is a fundamental component in various sectors such as construction, manufacturing, and wastewater management. When examining grating prices, several factors need consideration to ensure the best value and suitability for specific applications.

Another contributing pricing factor is the application environment. Grating designed for high-stress, chemically aggressive, or outdoor applications must adhere to strict specifications and might require additional coatings or treatments. These added processes are pivotal for enhancing lifespan and performance, inherently adding to the cost. Supplier expertise and reputation also play a crucial role. Established suppliers with proven expertise and certifications often offer products that, while possibly higher in price, ensure compliance with industry standards and regulations. This assurance of quality and performance is paramount, particularly in sectors where safety and compliance are critical. Global market dynamics, including raw material availability and international trade policies, can also sway grating prices. Recent years have shown that supply chain disruptions, tariffs, and trade agreements impact the availability and cost of raw materials, directly affecting grating product prices. Understanding the full scope of factors influencing grating prices empowers stakeholders to make informed decisions. Companies in search of grating solutions should consider not only the initial purchase cost but also the total cost of ownership, including installation, maintenance, and potential longevity afforded by quality materials and manufacturing integrity. In conclusion, the intricacies involved in grating pricing necessitate a comprehensive evaluation of material properties, manufacturing processes, supplier reliability, and market conditions. By focusing on these elements, consumers and businesses alike can optimize their purchasing decisions, ensuring that chosen grating meets performance requirements while offering economic efficiency and sustainability.

Another contributing pricing factor is the application environment. Grating designed for high-stress, chemically aggressive, or outdoor applications must adhere to strict specifications and might require additional coatings or treatments. These added processes are pivotal for enhancing lifespan and performance, inherently adding to the cost. Supplier expertise and reputation also play a crucial role. Established suppliers with proven expertise and certifications often offer products that, while possibly higher in price, ensure compliance with industry standards and regulations. This assurance of quality and performance is paramount, particularly in sectors where safety and compliance are critical. Global market dynamics, including raw material availability and international trade policies, can also sway grating prices. Recent years have shown that supply chain disruptions, tariffs, and trade agreements impact the availability and cost of raw materials, directly affecting grating product prices. Understanding the full scope of factors influencing grating prices empowers stakeholders to make informed decisions. Companies in search of grating solutions should consider not only the initial purchase cost but also the total cost of ownership, including installation, maintenance, and potential longevity afforded by quality materials and manufacturing integrity. In conclusion, the intricacies involved in grating pricing necessitate a comprehensive evaluation of material properties, manufacturing processes, supplier reliability, and market conditions. By focusing on these elements, consumers and businesses alike can optimize their purchasing decisions, ensuring that chosen grating meets performance requirements while offering economic efficiency and sustainability.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024