- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 16, 2025 03:38

Back to list

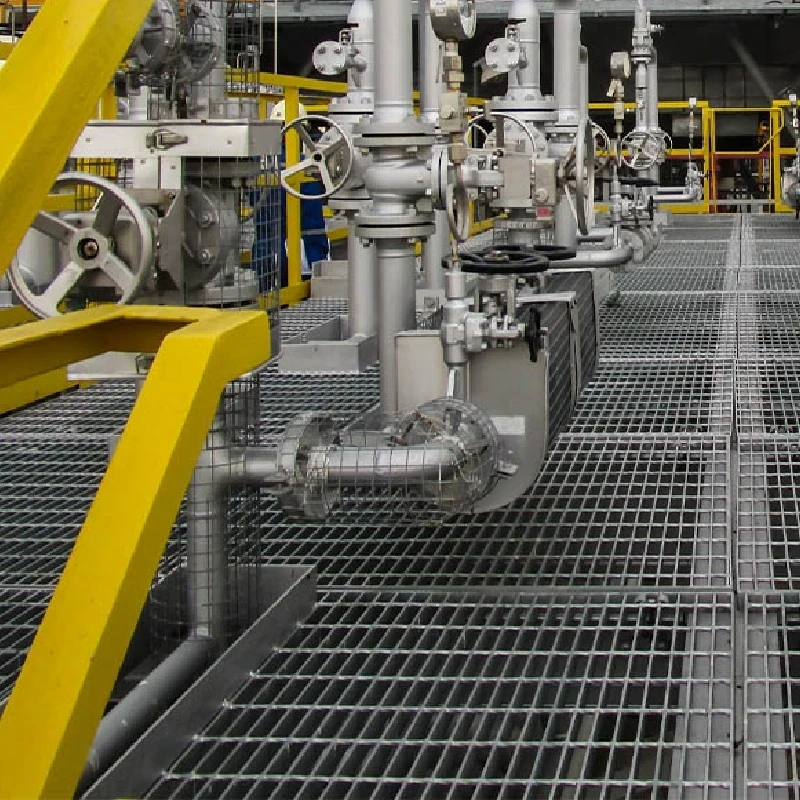

heavy duty steel grating price

Grating steel, a fundamental component in various industrial and commercial applications, continues to demand attention for its durability and practicality. It's commonly used for walkway platforms, flooring, fences, and drainage covers. The fluctuating price of grating steel in the current market presents a significant concern for businesses relying on this material. Understanding the dynamics behind its pricing and maintaining up-to-date information is crucial for both procurement specialists and industry operators.

According to industry authorities, keeping abreast of regulations and advancements in grating steel production is essential. Recent innovations in materials, like the development of more corrosion-resistant alloys or eco-friendly production techniques, are poised to influence market preferences and pricing. Engaging with industry associations and participating in related conferences can provide valuable insights and networking opportunities, further establishing one's authority in the field. Trustworthiness in purchasing grating steel is built through thorough supplier vetting and quality checks. Companies should ensure that potential suppliers meet industry standards, provide clear and transparent pricing structures, and possess a track record of reliability and quality. Adopting standardized testing and certification such as ISO can enhance credibility and reassure partners and clients of the product's reliability. Understanding these factors helps establish a comprehensive perspective on the grating steel market. Businesses should adopt a strategic approach, focusing on experience-derived insights, professional expertise, authoritative guidelines, and trustworthy sourcing to navigate the complexities of grating steel pricing effectively. By doing so, they can secure a competitive advantage, optimize their use of resources, and ultimately achieve greater operational efficiencies.

According to industry authorities, keeping abreast of regulations and advancements in grating steel production is essential. Recent innovations in materials, like the development of more corrosion-resistant alloys or eco-friendly production techniques, are poised to influence market preferences and pricing. Engaging with industry associations and participating in related conferences can provide valuable insights and networking opportunities, further establishing one's authority in the field. Trustworthiness in purchasing grating steel is built through thorough supplier vetting and quality checks. Companies should ensure that potential suppliers meet industry standards, provide clear and transparent pricing structures, and possess a track record of reliability and quality. Adopting standardized testing and certification such as ISO can enhance credibility and reassure partners and clients of the product's reliability. Understanding these factors helps establish a comprehensive perspective on the grating steel market. Businesses should adopt a strategic approach, focusing on experience-derived insights, professional expertise, authoritative guidelines, and trustworthy sourcing to navigate the complexities of grating steel pricing effectively. By doing so, they can secure a competitive advantage, optimize their use of resources, and ultimately achieve greater operational efficiencies.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024