- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 17, 2025 03:04

Back to list

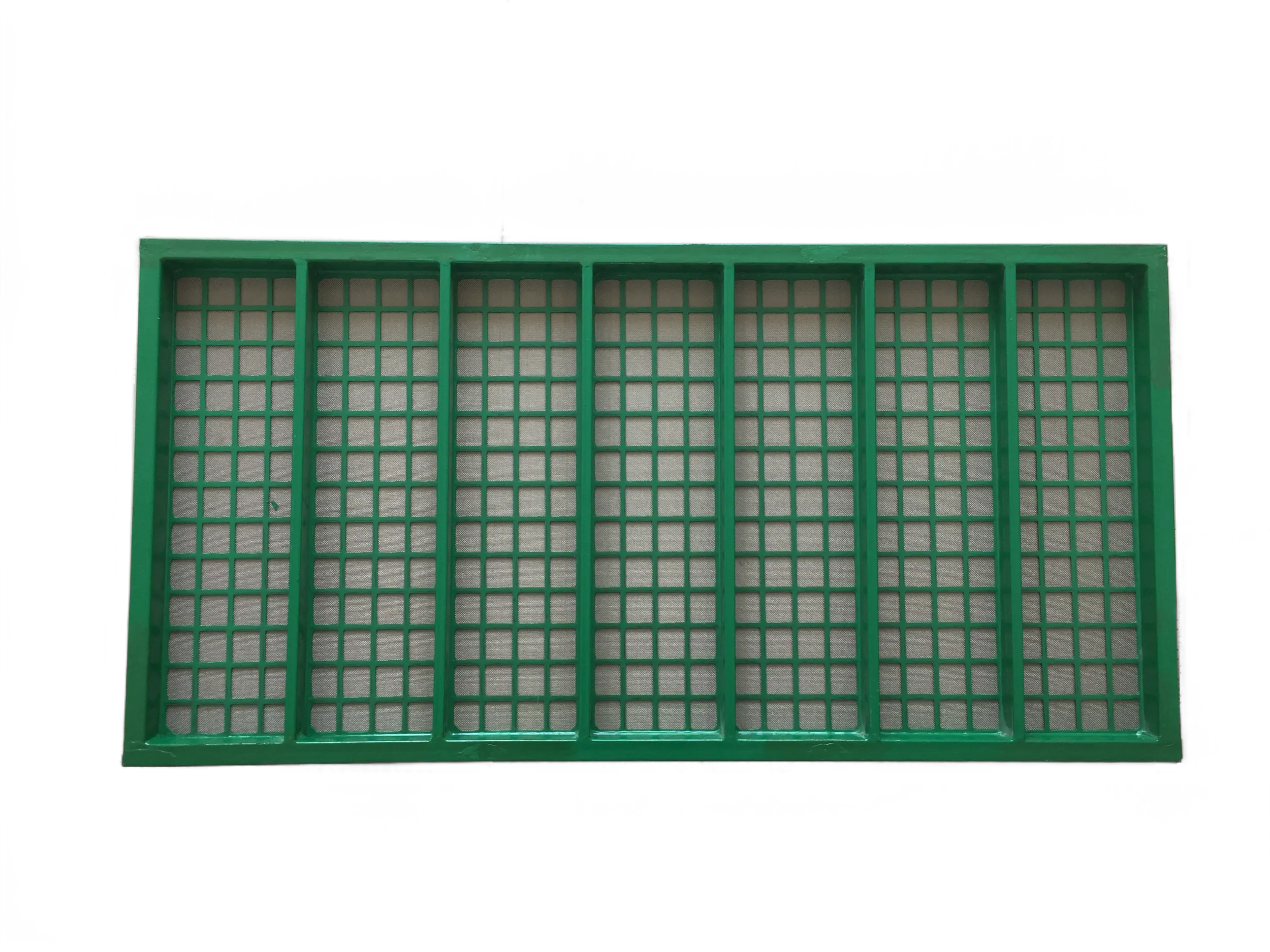

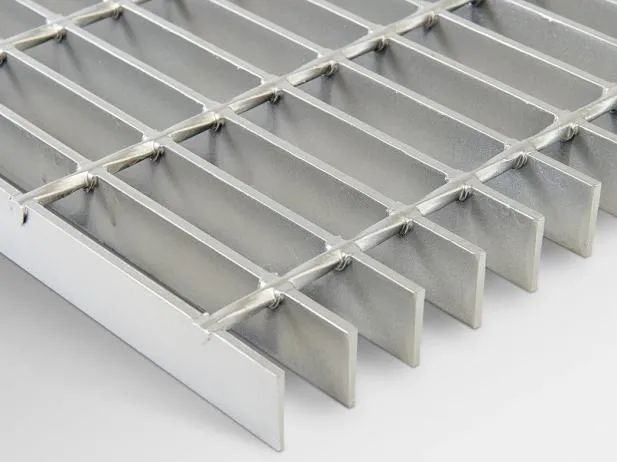

steel walkway grating

Steel grating stands out as a prominent solution in the realm of construction and industrial applications due to its durability and versatility. Made by weaving and welding a series of bearing bars and cross bars, steel gratings form a lattice that's unparalleled in strength and load-bearing capabilities. The design allows for easy installation, low maintenance, and outstanding longevity even under challenging conditions.

Trustworthiness is further enhanced by the sustainable and economic benefits of using steel grating. Many manufacturers undertake eco-friendly initiatives, emphasizing recycling and the use of sustainable materials in production. This commitment to environmental responsibility is complemented by the product's cost-effectiveness. Steel grating requires minimal maintenance over time, saving on repair and replacement costs. Moreover, its ease of installation reduces labor time and expenses, providing long-term financial and operational advantages. Moreover, the product's versatility extends beyond traditional industrial and construction roles. Its application in architectural works is a testament to its adaptability and functionality. Designers and artists incorporate steel grating into modern aesthetics, creating compelling installations that marry strength with visual intrigue. Indeed, innovations in manufacturing processes have allowed for greater customization and integration into creative endeavors, broadening its appeal and utility in non-traditional domains. In conclusion, steel grating emerges as a critical material backed by experience, expertise, authority, and trust. Its multifaceted applications and benefits across numerous sectors render it an irreplaceable asset. The endurance and flexibility it offers are mirrored by substantial endorsements from leading industry authorities, backed by proven compliance with international standards. Not only a pillar of practical construction and industrial use, steel grating is also an increasingly respected player in sustainable and creative spheres, revealing its dynamic and transformative nature in the modern world.

Trustworthiness is further enhanced by the sustainable and economic benefits of using steel grating. Many manufacturers undertake eco-friendly initiatives, emphasizing recycling and the use of sustainable materials in production. This commitment to environmental responsibility is complemented by the product's cost-effectiveness. Steel grating requires minimal maintenance over time, saving on repair and replacement costs. Moreover, its ease of installation reduces labor time and expenses, providing long-term financial and operational advantages. Moreover, the product's versatility extends beyond traditional industrial and construction roles. Its application in architectural works is a testament to its adaptability and functionality. Designers and artists incorporate steel grating into modern aesthetics, creating compelling installations that marry strength with visual intrigue. Indeed, innovations in manufacturing processes have allowed for greater customization and integration into creative endeavors, broadening its appeal and utility in non-traditional domains. In conclusion, steel grating emerges as a critical material backed by experience, expertise, authority, and trust. Its multifaceted applications and benefits across numerous sectors render it an irreplaceable asset. The endurance and flexibility it offers are mirrored by substantial endorsements from leading industry authorities, backed by proven compliance with international standards. Not only a pillar of practical construction and industrial use, steel grating is also an increasingly respected player in sustainable and creative spheres, revealing its dynamic and transformative nature in the modern world.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024