- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 17, 2025 02:40

Back to list

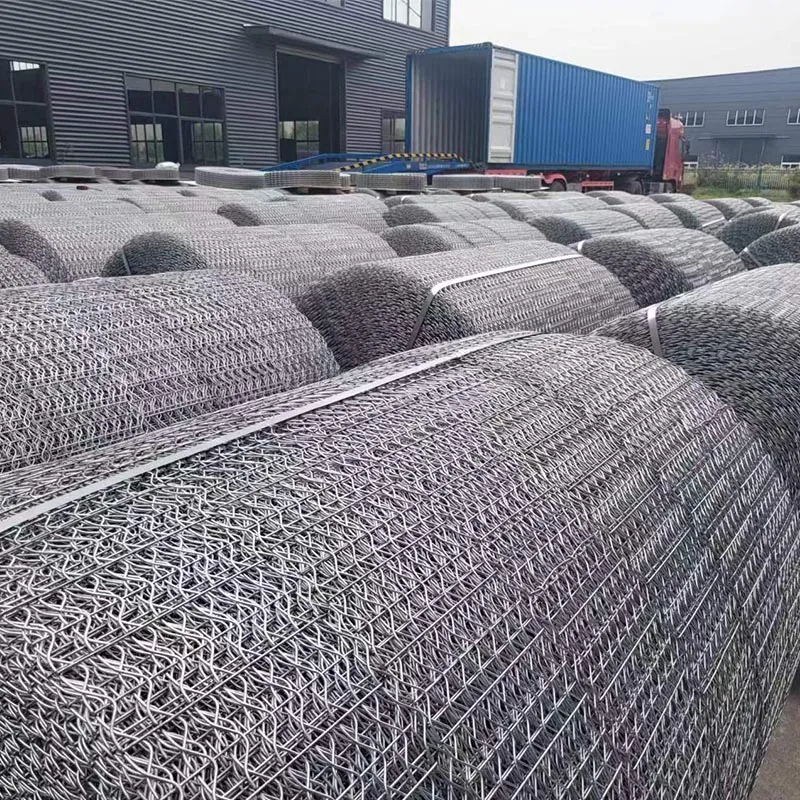

metal grating for sale

Metal grating is an essential component used across various industries, offering a range of applications and benefits that are both practical and durable. Understanding its properties, uses, and advantages can provide valuable insights for industries looking to improve efficiency, safety, and cost-effectiveness.

Safety is a paramount consideration across all its applications. Metal grating offers slip resistance, making it a preferred choice in environments where oils, chemicals, or water might create hazardous conditions. The grating surface is commonly etched or incorporates serrated edges to further enhance grip, providing a safer surface for pedestrian and vehicular traffic. From an environmental perspective, metal grating is recyclable and sustainable. Many companies favor it as a material of choice not only due to its longevity but also because of its reduced environmental footprint. Once it reaches the end of its useful life, metal grating can be recycled and transformed into new products, contributing to a circular economy. Selecting the right type of metal grating involves considering factors such as load requirements, exposure to elements, and specific industrial standards. Consulting with engineers and industry experts can provide the necessary guidance to ensure that the chosen grating meets the operational and safety demands of your application. In terms of cost-effectiveness, while the initial investment in metal grating might seem significant, its durability and low maintenance requirements often lead to long-term savings. The longevity of metal gratings reduces the need for frequent replacements or repairs, thereby lowering overall operational costs. Finally, advancements in manufacturing processes have led to the development of custom metal grating solutions. Companies now offer bespoke designs tailored to specific industry needs, reinforcing the importance of engaging with qualified manufacturers who possess the expertise and authority in metal grating solutions. Investing in metal grating is not merely about choosing a product. It involves selecting a solution that enhances safety, supports infrastructure, contributes to sustainability, and upholds the enduring reliability that industries depend on. Whether you're an engineer, architect, or facility manager, understanding and implementing metal grating can substantially improve operational efficiencies, maintain safety standards, and ensure industry compliance.

Safety is a paramount consideration across all its applications. Metal grating offers slip resistance, making it a preferred choice in environments where oils, chemicals, or water might create hazardous conditions. The grating surface is commonly etched or incorporates serrated edges to further enhance grip, providing a safer surface for pedestrian and vehicular traffic. From an environmental perspective, metal grating is recyclable and sustainable. Many companies favor it as a material of choice not only due to its longevity but also because of its reduced environmental footprint. Once it reaches the end of its useful life, metal grating can be recycled and transformed into new products, contributing to a circular economy. Selecting the right type of metal grating involves considering factors such as load requirements, exposure to elements, and specific industrial standards. Consulting with engineers and industry experts can provide the necessary guidance to ensure that the chosen grating meets the operational and safety demands of your application. In terms of cost-effectiveness, while the initial investment in metal grating might seem significant, its durability and low maintenance requirements often lead to long-term savings. The longevity of metal gratings reduces the need for frequent replacements or repairs, thereby lowering overall operational costs. Finally, advancements in manufacturing processes have led to the development of custom metal grating solutions. Companies now offer bespoke designs tailored to specific industry needs, reinforcing the importance of engaging with qualified manufacturers who possess the expertise and authority in metal grating solutions. Investing in metal grating is not merely about choosing a product. It involves selecting a solution that enhances safety, supports infrastructure, contributes to sustainability, and upholds the enduring reliability that industries depend on. Whether you're an engineer, architect, or facility manager, understanding and implementing metal grating can substantially improve operational efficiencies, maintain safety standards, and ensure industry compliance.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024