- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 17, 2025 02:18

Back to list

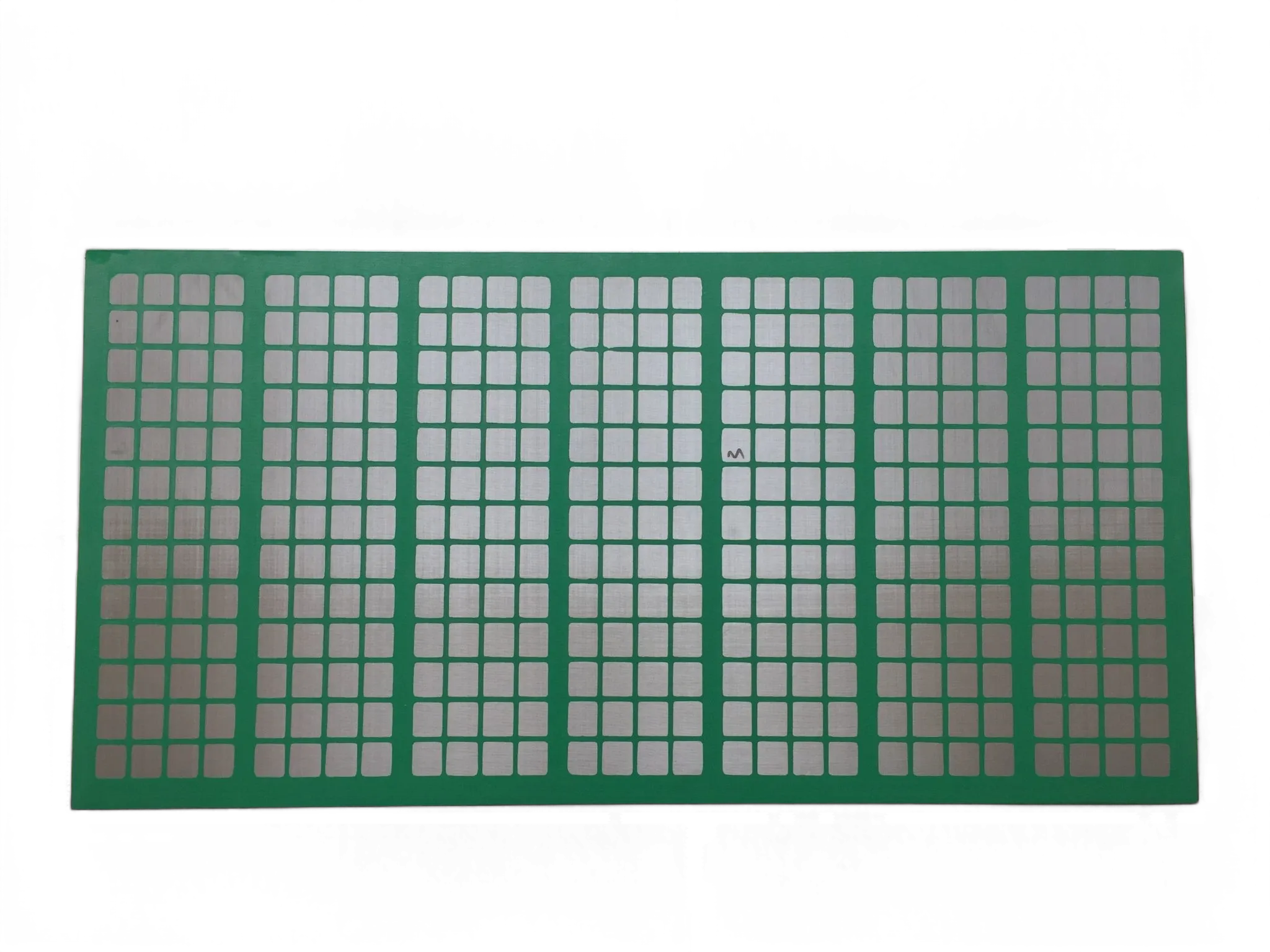

heavy-duty welded bar grating

Bar grating is a critical component in modern industrial and construction settings, celebrated not only for its strength and durability but also for its versatility in numerous applications. For prospective users and industry experts, understanding what bar grating is, its applications, materials, and benefits is cornerstone knowledge for selecting the right product for various structural and decorative needs.

Beyond functional benefits, bar grating is also lauded for its economic advantages. The durability of well-maintained steel grating provides a long-term solution that minimizes replacement costs. Moreover, its ease of installation - given its light weight compared to solid flooring options and adaptability to custom sizes - reduces labor costs and downtime during implementation. Material coatings and finishes further enhance the scope of bar grating’s application and longevity. Galvanization, for instance, offers a protective zinc coating that defends against rust in carbon steel, extending its usability in harsh environments. For tailored aesthetics, powder coatings can add a splash of color, blending practicality with design preferences in commercial spaces or public installations. Addressing the importance of expertise when selecting bar grating, one must consider load requirements, environmental exposure, and intended use. Partnering with a reputable supplier or manufacturer can help navigate the complexities of these essential factors. Furthermore, precise measurements and adherence to safety standards are imperative, as improperly specified or installed grating can jeopardize both structural integrity and safety. In summary, bar grating stands as a testament to industrial ingenuity, marrying functionality with versatility. Its myriad applications across industries underscore its essential role in modern construction and design. By leveraging expert knowledge and trusting quality materials, businesses can harness bar grating’s full potential, ensuring safety, durability, and cost-efficiency across projects. Whether for heavy industrial use or as a sleek element in architectural design, understanding the myriad facets of bar grating enhances decision-making and application success.

Beyond functional benefits, bar grating is also lauded for its economic advantages. The durability of well-maintained steel grating provides a long-term solution that minimizes replacement costs. Moreover, its ease of installation - given its light weight compared to solid flooring options and adaptability to custom sizes - reduces labor costs and downtime during implementation. Material coatings and finishes further enhance the scope of bar grating’s application and longevity. Galvanization, for instance, offers a protective zinc coating that defends against rust in carbon steel, extending its usability in harsh environments. For tailored aesthetics, powder coatings can add a splash of color, blending practicality with design preferences in commercial spaces or public installations. Addressing the importance of expertise when selecting bar grating, one must consider load requirements, environmental exposure, and intended use. Partnering with a reputable supplier or manufacturer can help navigate the complexities of these essential factors. Furthermore, precise measurements and adherence to safety standards are imperative, as improperly specified or installed grating can jeopardize both structural integrity and safety. In summary, bar grating stands as a testament to industrial ingenuity, marrying functionality with versatility. Its myriad applications across industries underscore its essential role in modern construction and design. By leveraging expert knowledge and trusting quality materials, businesses can harness bar grating’s full potential, ensuring safety, durability, and cost-efficiency across projects. Whether for heavy industrial use or as a sleek element in architectural design, understanding the myriad facets of bar grating enhances decision-making and application success.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024