- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 21:27

Back to list

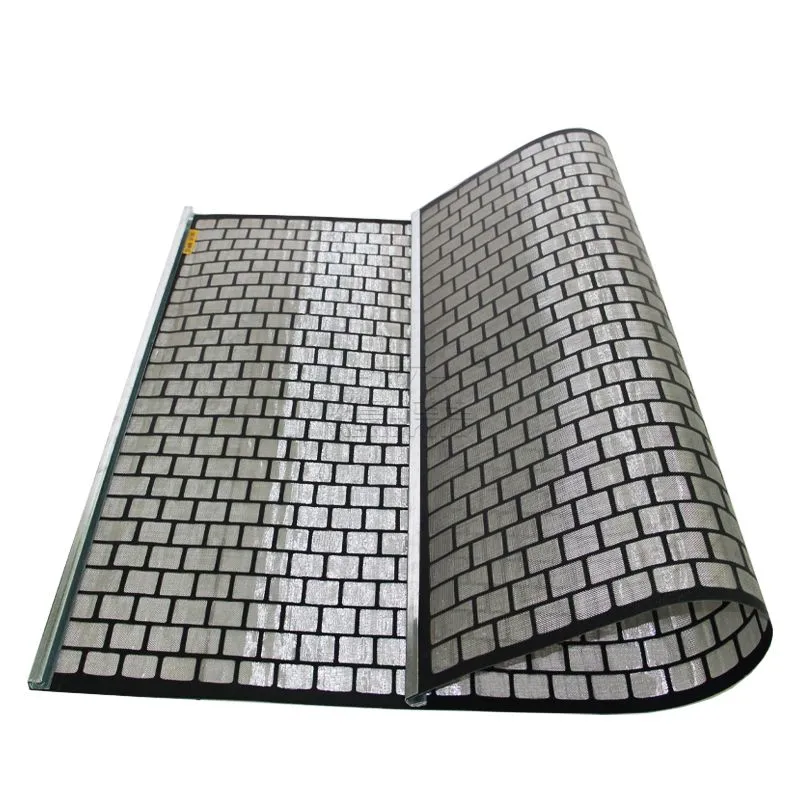

welded steel grating

Welded steel grating stands as a pinnacle of engineering excellence and durability in the landscape of industrial materials. Born from a process that fuses the connecting bars to the bearing bars through welded intersections, this grating provides unmatched strength and load-bearing capacity. Its application spans a multitude of industries, providing solutions that range from flooring systems to security installations.

Trustworthiness is not solely about the material's physical qualities but also the assurance provided by comprehensive testing and certifications. Top manufacturers execute stringent quality assurance processes, providing clients with certifications and test results that validate the product's load capacity and durability under specific conditions. Installation contractors frequently report ease of fitting due to the grating's precise manufacturing and cutting-to-size, which reduces installation time and cost, further alleviating project management concerns. The enrichment of environments through welded steel grating is further illustrated in its environmental adaptability. With options available for galvanization or powder coating, the grating can endure extreme weather, such as high humidity, salt exposure, or acidic conditions, thus reinforcing its resilience and lifecycle. Professionals in environmental design highlight the material's recyclability, which aligns with contemporary sustainability goals, making it an appealing choice for eco-conscious clients. In summary, welded steel grating is an embodiment of engineering prowess and reliability. Its applicability across various demanding scenarios proves invaluable, tied closely with the expert craftsmanship of its production and rigorous compliance with safety and quality standards. Such facets underscore its authority in industrial applications, while experiential testimonies and certification-backed reliability augment trust, making it an indispensable material in any project that demands strength, safety, and durability.

Trustworthiness is not solely about the material's physical qualities but also the assurance provided by comprehensive testing and certifications. Top manufacturers execute stringent quality assurance processes, providing clients with certifications and test results that validate the product's load capacity and durability under specific conditions. Installation contractors frequently report ease of fitting due to the grating's precise manufacturing and cutting-to-size, which reduces installation time and cost, further alleviating project management concerns. The enrichment of environments through welded steel grating is further illustrated in its environmental adaptability. With options available for galvanization or powder coating, the grating can endure extreme weather, such as high humidity, salt exposure, or acidic conditions, thus reinforcing its resilience and lifecycle. Professionals in environmental design highlight the material's recyclability, which aligns with contemporary sustainability goals, making it an appealing choice for eco-conscious clients. In summary, welded steel grating is an embodiment of engineering prowess and reliability. Its applicability across various demanding scenarios proves invaluable, tied closely with the expert craftsmanship of its production and rigorous compliance with safety and quality standards. Such facets underscore its authority in industrial applications, while experiential testimonies and certification-backed reliability augment trust, making it an indispensable material in any project that demands strength, safety, and durability.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024