- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 22:06

Back to list

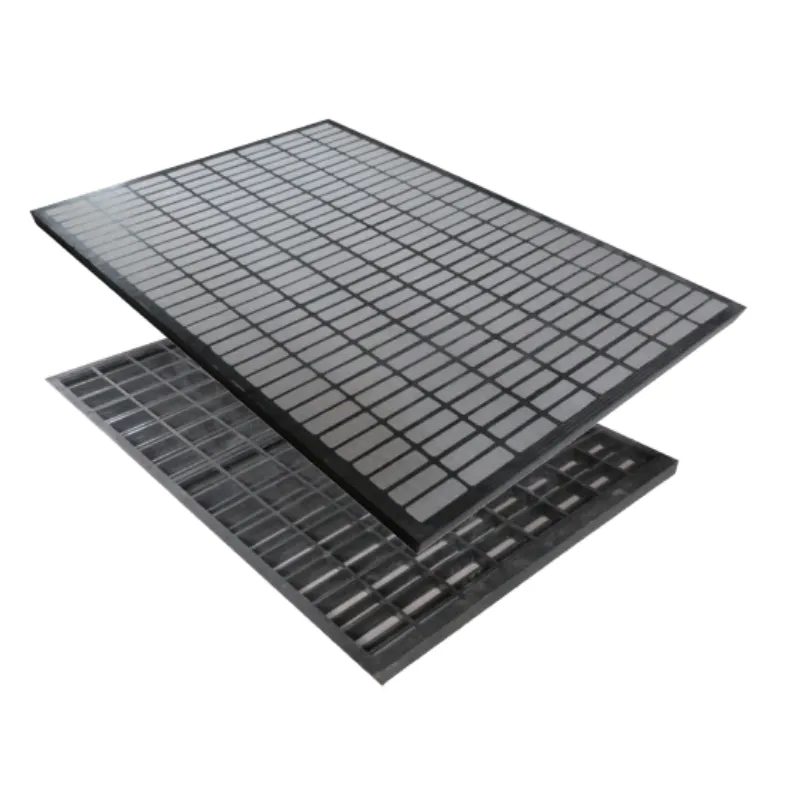

welded bar grating

Welded bar grating has become an essential component for a myriad of industrial applications due to its robustness, versatility, and aesthetic appeal. Its rising popularity among engineers and architects can be attributed to its ability to fuse strength with functionality. The gripping power of welded bar grating is derived from its unique construction—where each load-bearing bar is welded at every crossbar intersection, ensuring a permanent joint that can withstand significant pressures.

Authoritativeness in the realm of welded bar grating can be observed through certified manufacturing processes and adherence to stringent international standards. Companies with ISO certification, for instance, demonstrate their commitment to quality and consistency, thereby instilling confidence in their products. Expert manufacturers often provide comprehensive support, from the initial design to installation, and ongoing maintenance, ensuring their products deliver optimal performance over time. Trustworthiness in welded bar grating products can often be gauged through the testimonials of previous clients and case studies showcasing successful installations. Prospective buyers should seek out businesses with an established track record of reliability and positive client feedback. This not only ensures product quality but also highlights the manufacturer’s ability to address any technical issues that may arise post-installation. Through visitor insights, it is apparent that welded bar grating is not just about function; it's about providing a smart, cost-effective, and visually appealing solution. It is this amalgamation of practical benefits and aesthetic flexibility that makes it a preferred choice across industries. Companies continually innovate in this domain, offering grating solutions that are lighter, stronger, and more environmentally friendly, meeting the ever-evolving needs of modern engineering challenges. In summary, welded bar grating is a quintessential product in both industrial and architectural applications, offering unmatched strength, durability, and adaptability. For those in industries requiring resilient, safe, and versatile flooring solutions, welded bar grating proves to be an unbeatable choice. By cooperating with expert providers, clients ensure that they are leveraging cutting-edge technology and unparalleled industry experience to bring their projects to life effectively and efficiently.

Authoritativeness in the realm of welded bar grating can be observed through certified manufacturing processes and adherence to stringent international standards. Companies with ISO certification, for instance, demonstrate their commitment to quality and consistency, thereby instilling confidence in their products. Expert manufacturers often provide comprehensive support, from the initial design to installation, and ongoing maintenance, ensuring their products deliver optimal performance over time. Trustworthiness in welded bar grating products can often be gauged through the testimonials of previous clients and case studies showcasing successful installations. Prospective buyers should seek out businesses with an established track record of reliability and positive client feedback. This not only ensures product quality but also highlights the manufacturer’s ability to address any technical issues that may arise post-installation. Through visitor insights, it is apparent that welded bar grating is not just about function; it's about providing a smart, cost-effective, and visually appealing solution. It is this amalgamation of practical benefits and aesthetic flexibility that makes it a preferred choice across industries. Companies continually innovate in this domain, offering grating solutions that are lighter, stronger, and more environmentally friendly, meeting the ever-evolving needs of modern engineering challenges. In summary, welded bar grating is a quintessential product in both industrial and architectural applications, offering unmatched strength, durability, and adaptability. For those in industries requiring resilient, safe, and versatile flooring solutions, welded bar grating proves to be an unbeatable choice. By cooperating with expert providers, clients ensure that they are leveraging cutting-edge technology and unparalleled industry experience to bring their projects to life effectively and efficiently.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024