- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 22:51

Back to list

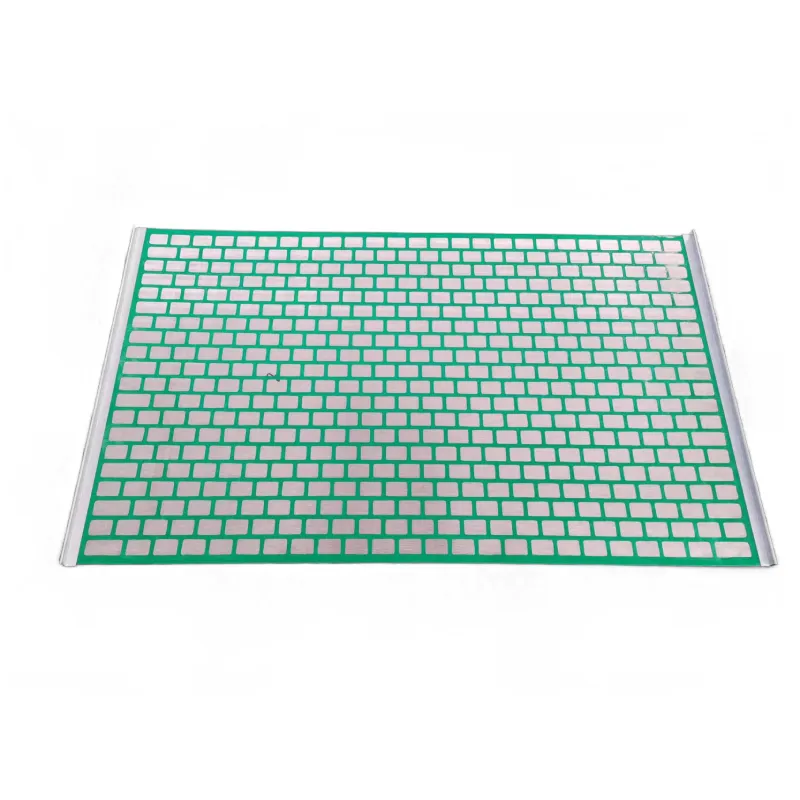

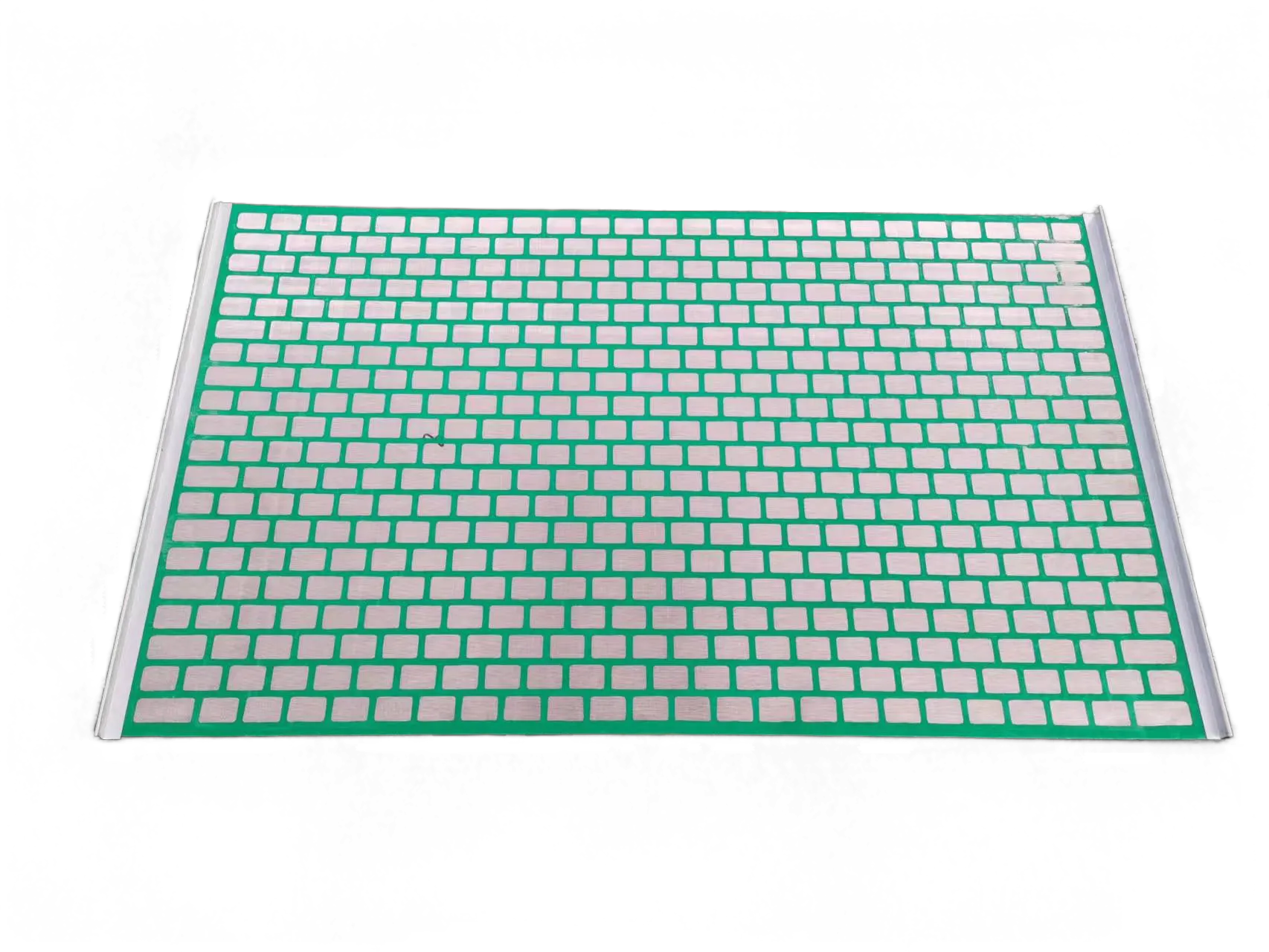

heavy-duty welded bar grating

Heavy-duty welded bar grating is a staple in industrial flooring systems, providing unparalleled durability and strength. Unlike other types of grating, the heavy-duty welded variety is specifically designed to withstand extreme loads and harsh conditions, making it indispensable in environments such as manufacturing plants, refineries, and transportation facilities.

From an authoritative standpoint, suppliers of heavy-duty welded bar grating must adhere to strict quality standards and specifications. Compliance with standards such as the American National Standards Institute (ANSI) or other regional equivalents is mandatory. These standards ensure that each piece of grating meets the rigorous demands of industrial applications, providing assurance to clients that they are investing in a reliable product. Companies that manufacture these products must possess a deep understanding of metallurgy, structural engineering, and production processes to consistently deliver grating that can endure the test of time. Trust in heavy-duty welded bar grating also comes from its proven track record in challenging applications. Industries that operate in high-pressure environments, such as oil and gas, mining, and chemical production, often rely on this robust flooring solution. The confidence these industries place in the product underscores its reputation as a trustworthy component of their infrastructure. When selecting heavy-duty welded bar grating, working with a reputable supplier is crucial. An experienced supplier can offer insightful guidance on the most suitable grating type for specific applications. They can advise on the appropriate bar thickness, spacing, and material type, whether it be stainless steel, carbon steel, or aluminum, to optimize performance and longevity. Furthermore, a reputable supplier will provide installation support, ensuring that the grating is secured correctly to maximize its functional lifespan and safety. In summary, heavy-duty welded bar grating is an invaluable asset to industries that demand reliability and strength from their flooring systems. Its expert construction, compliance with authoritative standards, and proven performance make it a trusted choice in the industrial sphere. Whether dealing with heavy machinery, intense foot traffic, or corrosive environments, this type of grating stands as a testament to the advancements in industrial design and engineering. For facilities seeking a robust solution to their flooring needs, heavy-duty welded bar grating offers a customized, durable, and reliable choice.

From an authoritative standpoint, suppliers of heavy-duty welded bar grating must adhere to strict quality standards and specifications. Compliance with standards such as the American National Standards Institute (ANSI) or other regional equivalents is mandatory. These standards ensure that each piece of grating meets the rigorous demands of industrial applications, providing assurance to clients that they are investing in a reliable product. Companies that manufacture these products must possess a deep understanding of metallurgy, structural engineering, and production processes to consistently deliver grating that can endure the test of time. Trust in heavy-duty welded bar grating also comes from its proven track record in challenging applications. Industries that operate in high-pressure environments, such as oil and gas, mining, and chemical production, often rely on this robust flooring solution. The confidence these industries place in the product underscores its reputation as a trustworthy component of their infrastructure. When selecting heavy-duty welded bar grating, working with a reputable supplier is crucial. An experienced supplier can offer insightful guidance on the most suitable grating type for specific applications. They can advise on the appropriate bar thickness, spacing, and material type, whether it be stainless steel, carbon steel, or aluminum, to optimize performance and longevity. Furthermore, a reputable supplier will provide installation support, ensuring that the grating is secured correctly to maximize its functional lifespan and safety. In summary, heavy-duty welded bar grating is an invaluable asset to industries that demand reliability and strength from their flooring systems. Its expert construction, compliance with authoritative standards, and proven performance make it a trusted choice in the industrial sphere. Whether dealing with heavy machinery, intense foot traffic, or corrosive environments, this type of grating stands as a testament to the advancements in industrial design and engineering. For facilities seeking a robust solution to their flooring needs, heavy-duty welded bar grating offers a customized, durable, and reliable choice.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024