- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 23:35

Back to list

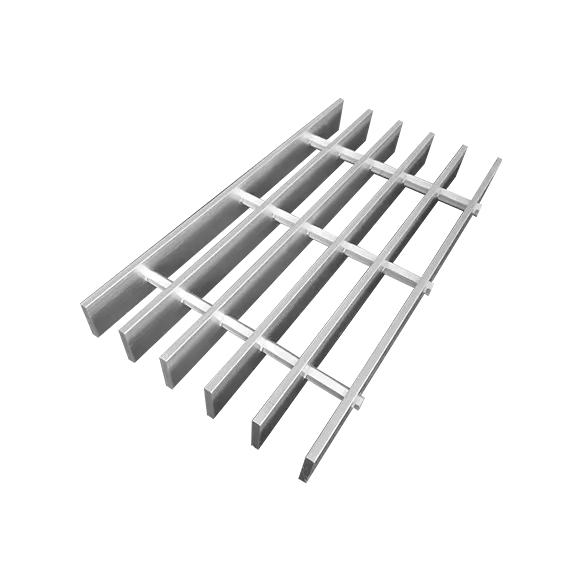

steel walkway grating

Press-locked steel grating stands as a cornerstone in the contemporary landscape of industrial flooring, infrastructure, and architectural applications, offering unmatched durability, safety, and versatility. The unparalleled experience users gain from press-locked steel gratings comes from its unique manufacturing process where flat bars are inserted into pre-punched holes in the cross bars. This method enhances the strength of the product without sacrificing the lightweight advantage that steel is known for, giving it a distinctive edge in high-demand environments.

Trustworthiness, especially in procurement, is substantially heightened with the use of press-locked steel grating due to its balance of long-term cost efficiency and performance. While the initial investment might be higher when compared to alternatives like welded mesh or plastic gratings, the lower maintenance requirements and durable nature of steel make it a cost-effective solution in the long run. Reliable suppliers offer warranties and support, reflecting confidence in their products and providing peace of mind to buyers who need scheduled maintenance and consultation throughout the product’s lifecycle. Feedback from users frequently highlights the safety features unique to press-locked steel grating. Its non-slip surface provides excellent traction even in wet conditions, greatly reducing workplace accidents. Additional safety features include the grating’s ability to handle various load capacities and provide stability to those navigating elevated walkways or platforms. This inherent safety ensures compliance with occupational health standards, a critical factor in any industry. Moreover, as sustainability becomes integral to modern construction approaches, press-locked steel grating does not fall short. Steel is 100% recyclable, and its durability significantly reduces the need for frequent replacements, minimizing waste over time. This sustainability angle not only aligns with environmental responsibilities but also elevates the long-term value proposition of press-locked gratings compared to other materials. In conclusion, the comprehensive advantages of press-locked steel grating—from its robust physical characteristics and aesthetic adaptability to its certified safety standards and environmental benefits—make it a preferred choice for industry professionals. Its unmatched ability to deliver reliable performance while maintaining cost-efficiency positions it as a staple in engineering and architectural applications across the globe, thereby validating its growing prominence in complex, modern construction projects.

Trustworthiness, especially in procurement, is substantially heightened with the use of press-locked steel grating due to its balance of long-term cost efficiency and performance. While the initial investment might be higher when compared to alternatives like welded mesh or plastic gratings, the lower maintenance requirements and durable nature of steel make it a cost-effective solution in the long run. Reliable suppliers offer warranties and support, reflecting confidence in their products and providing peace of mind to buyers who need scheduled maintenance and consultation throughout the product’s lifecycle. Feedback from users frequently highlights the safety features unique to press-locked steel grating. Its non-slip surface provides excellent traction even in wet conditions, greatly reducing workplace accidents. Additional safety features include the grating’s ability to handle various load capacities and provide stability to those navigating elevated walkways or platforms. This inherent safety ensures compliance with occupational health standards, a critical factor in any industry. Moreover, as sustainability becomes integral to modern construction approaches, press-locked steel grating does not fall short. Steel is 100% recyclable, and its durability significantly reduces the need for frequent replacements, minimizing waste over time. This sustainability angle not only aligns with environmental responsibilities but also elevates the long-term value proposition of press-locked gratings compared to other materials. In conclusion, the comprehensive advantages of press-locked steel grating—from its robust physical characteristics and aesthetic adaptability to its certified safety standards and environmental benefits—make it a preferred choice for industry professionals. Its unmatched ability to deliver reliable performance while maintaining cost-efficiency positions it as a staple in engineering and architectural applications across the globe, thereby validating its growing prominence in complex, modern construction projects.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024