- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 12, 2025 00:29

Back to list

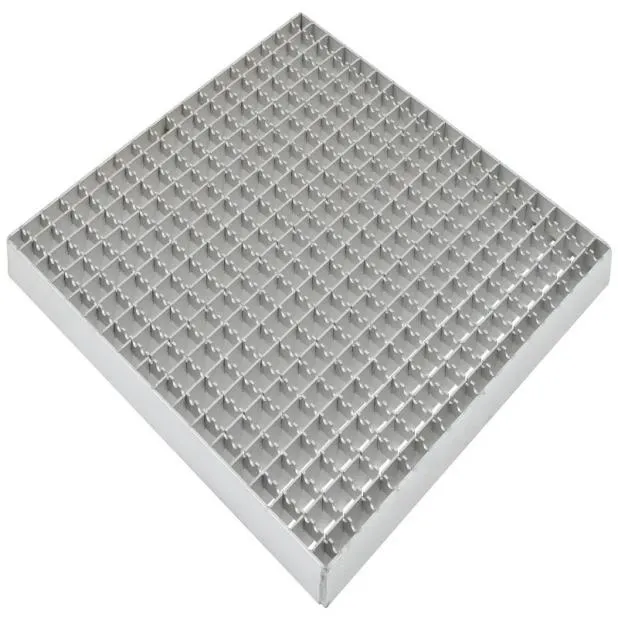

steel walkway grating

Swage-locked grating is revolutionizing industries with its robust construction, ease of installation, and remarkable durability. As industries continually strive for efficiency and reliability, this type of grating provides solutions that meet various structural and safety needs.

Environmental considerations are also at the forefront when discussing swage-locked grating. Manufactured primarily from recyclable materials, these gratings align with sustainable practices, reducing their carbon footprint. This ecological adaptability enhances their desirability in sectors increasingly holding sustainability as the new benchmark for procurement. Onsite installation of swage-locked grating also stands out as a key benefit. Builders appreciate the ease with which these panels can be fitted into complex installations, often requiring fewer labor hours and tools. Such efficiency is critical in project timelines, cutting down on potential delays and associated costs. The trustworthiness of swage-locked grating is reinforced by its wide adoption across industries and the strong feedback from professionals who have integrated it into their infrastructure. Testimonials from engineers emphasize the components' reliability, noting minimal incidents of failure even under intensive use. Manufacturer certifications further endorse these claims, offering peace of mind with verifiable data to back performance warranties. In summary, swage-locked grating emerges as a paragon of modern industrial needs, combining expertise in material science with practical usability. It meets demanding standards of experience and authority, promising end-users a robust, sustainable, and aesthetically pleasing solution. The ongoing development in this field continues to refine and expand its application, setting the standard for future innovations in grating technology.

Environmental considerations are also at the forefront when discussing swage-locked grating. Manufactured primarily from recyclable materials, these gratings align with sustainable practices, reducing their carbon footprint. This ecological adaptability enhances their desirability in sectors increasingly holding sustainability as the new benchmark for procurement. Onsite installation of swage-locked grating also stands out as a key benefit. Builders appreciate the ease with which these panels can be fitted into complex installations, often requiring fewer labor hours and tools. Such efficiency is critical in project timelines, cutting down on potential delays and associated costs. The trustworthiness of swage-locked grating is reinforced by its wide adoption across industries and the strong feedback from professionals who have integrated it into their infrastructure. Testimonials from engineers emphasize the components' reliability, noting minimal incidents of failure even under intensive use. Manufacturer certifications further endorse these claims, offering peace of mind with verifiable data to back performance warranties. In summary, swage-locked grating emerges as a paragon of modern industrial needs, combining expertise in material science with practical usability. It meets demanding standards of experience and authority, promising end-users a robust, sustainable, and aesthetically pleasing solution. The ongoing development in this field continues to refine and expand its application, setting the standard for future innovations in grating technology.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024