- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 20:46

Back to list

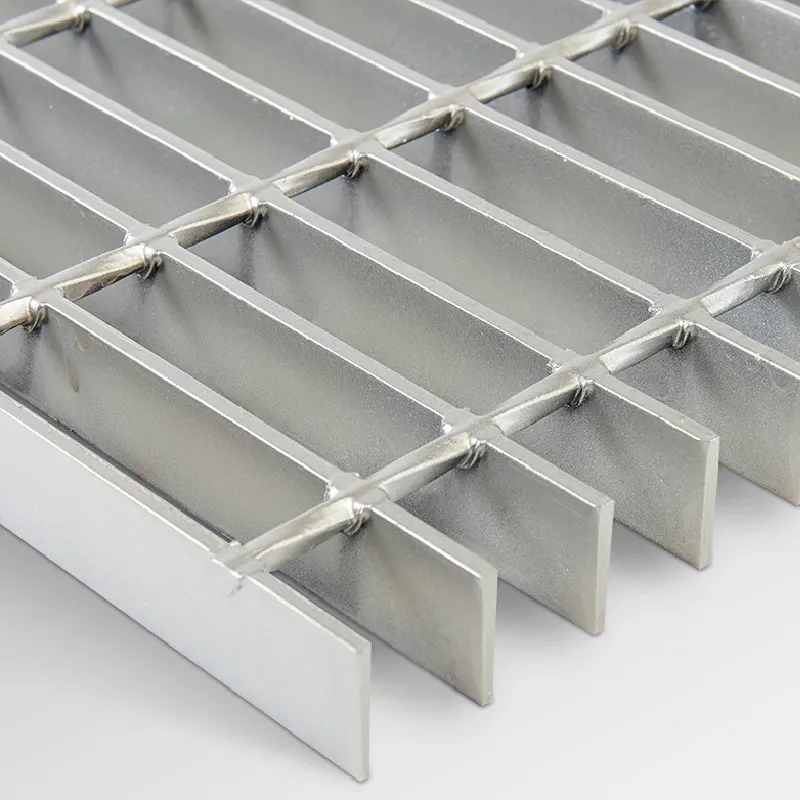

aluminum bar grating

Aluminum bar grating stands out as a practical choice for industrial and commercial applications, providing a unique combination of lightweight strength, durability, and versatility that other materials simply cannot match. Over the years, it has gained widespread acceptance in both architectural and industrial contexts due to these intrinsic qualities.

In terms of ease of use, aluminum bar grating's lightweight nature simplifies both handling and installation processes, making it a preferred material for contractors and project managers seeking efficiency and speed. This convenience does not diminish the grating’s toughness, however. The intrinsic resilience of aluminum allows it to maintain its structural integrity under significant strain, ensuring that safety standards are upheld throughout the lifespan of the installation. From the perspective of safety, aluminum grating provides excellent traction to prevent slips and falls, an essential feature in any setting where safety is a top priority. This quality can be further adjusted with specialized finishes that maximize grip to meet the specific requirements of high-risk environments. Industry experts recognize aluminum bar grating as a reliable solution that offers not just immediate performance benefits, but also long-term advantages in terms of maintenance and lifecycle costs. Its applicability across various challenging sectors stands as a testament to its versatility and robustness. Engineers, architects, and project managers continually seek out aluminum bar grating as their go-to material in scenarios where both environmental and mechanical stresses are in play. Utilizing aluminum bar grating allows for tailored solutions that meet stringent project demands while ensuring compliance with rigorous safety standards. As industries continue to evolve and demand smarter, more efficient building materials, aluminum bar grating will undeniably remain at the forefront, championed by those who prioritize quality, reliability, and sustainability in their projects.

In terms of ease of use, aluminum bar grating's lightweight nature simplifies both handling and installation processes, making it a preferred material for contractors and project managers seeking efficiency and speed. This convenience does not diminish the grating’s toughness, however. The intrinsic resilience of aluminum allows it to maintain its structural integrity under significant strain, ensuring that safety standards are upheld throughout the lifespan of the installation. From the perspective of safety, aluminum grating provides excellent traction to prevent slips and falls, an essential feature in any setting where safety is a top priority. This quality can be further adjusted with specialized finishes that maximize grip to meet the specific requirements of high-risk environments. Industry experts recognize aluminum bar grating as a reliable solution that offers not just immediate performance benefits, but also long-term advantages in terms of maintenance and lifecycle costs. Its applicability across various challenging sectors stands as a testament to its versatility and robustness. Engineers, architects, and project managers continually seek out aluminum bar grating as their go-to material in scenarios where both environmental and mechanical stresses are in play. Utilizing aluminum bar grating allows for tailored solutions that meet stringent project demands while ensuring compliance with rigorous safety standards. As industries continue to evolve and demand smarter, more efficient building materials, aluminum bar grating will undeniably remain at the forefront, championed by those who prioritize quality, reliability, and sustainability in their projects.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024