- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 20:05

Back to list

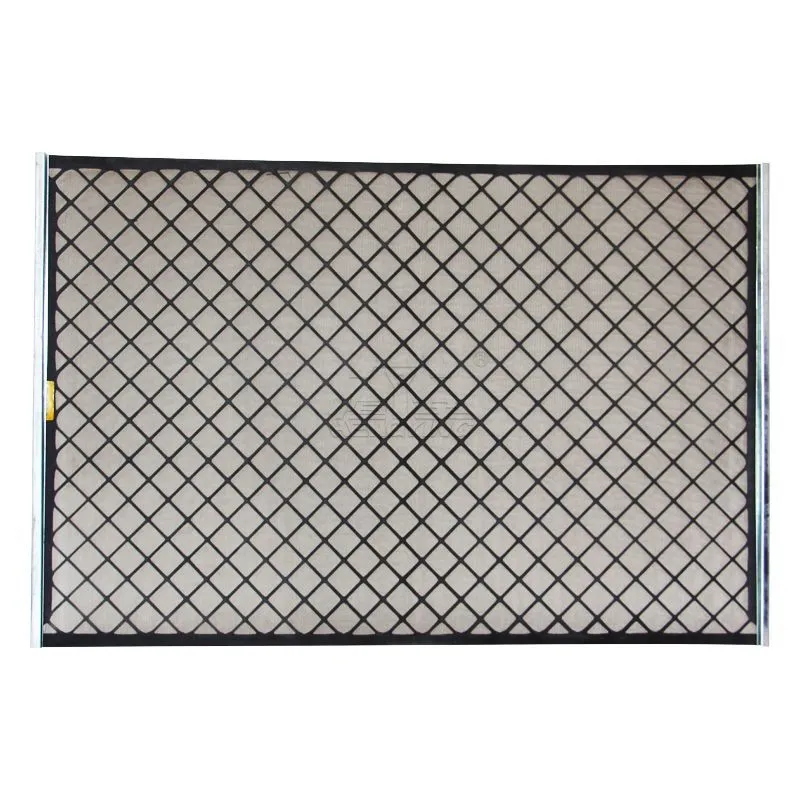

aluminum grating

Aluminum grating is a versatile material that has carved a niche in various industries due to its unique properties and wide array of applications. With decades of expertise in manufacturing, installation, and maintenance, I am here to share invaluable insights that enhance both the practical understanding and strategic utilization of aluminum grating.

A critical aspect in deploying aluminum grating effectively is understanding the load-bearing requirements. Choosing the correct grating type—whether it’s bar grating, plank grating, or expanded aluminum grating—can make all the difference in structural performance. My experience underscores the importance of consulting with structural engineers early in the project design to assess load constraints and ensure optimal selection and placement of grating. In terms of customization, aluminum grating supports numerous configurations and finishes, lending itself to a variety of aesthetic and functional requirements. From anodized coatings for added protection to powder coatings for enhanced visual appeal, clients appreciate the flexibility offered by aluminum grating. This customization ability enables alignment with corporate branding or interior design specifications, broadening its applicability beyond strictly functional domains. When it comes to installation, aluminum grating supports an array of fastening methods that cater to specific project needs, from welding to bolting or pressure-locking. Drawing from numerous installation projects, I recommend that factors such as environmental impact, potential disassembly, and load dynamics be carefully considered when selecting the fastening technique. Trustworthiness is further solidified through regulatory compliance. Aluminum grating often meets or exceeds standards set forth by organizations like the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). Clients and project managers should seek products from reputable manufacturers who rigorously adhere to these standards, ensuring that quality and safety are uncompromised. In conclusion, leveraging aluminum grating offers a blend of performance, reliability, and versatility unmatched by traditional materials. My years in the industry reaffirm that understanding the environment, load requirements, and necessary regulatory compliance are key drivers for maximizing the efficacy of aluminum grating projects. Each step, from selection to installation, influences the outcome and value derived from aluminum grating, making these projects a worthwhile investment in both industrial and commercial settings.

A critical aspect in deploying aluminum grating effectively is understanding the load-bearing requirements. Choosing the correct grating type—whether it’s bar grating, plank grating, or expanded aluminum grating—can make all the difference in structural performance. My experience underscores the importance of consulting with structural engineers early in the project design to assess load constraints and ensure optimal selection and placement of grating. In terms of customization, aluminum grating supports numerous configurations and finishes, lending itself to a variety of aesthetic and functional requirements. From anodized coatings for added protection to powder coatings for enhanced visual appeal, clients appreciate the flexibility offered by aluminum grating. This customization ability enables alignment with corporate branding or interior design specifications, broadening its applicability beyond strictly functional domains. When it comes to installation, aluminum grating supports an array of fastening methods that cater to specific project needs, from welding to bolting or pressure-locking. Drawing from numerous installation projects, I recommend that factors such as environmental impact, potential disassembly, and load dynamics be carefully considered when selecting the fastening technique. Trustworthiness is further solidified through regulatory compliance. Aluminum grating often meets or exceeds standards set forth by organizations like the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). Clients and project managers should seek products from reputable manufacturers who rigorously adhere to these standards, ensuring that quality and safety are uncompromised. In conclusion, leveraging aluminum grating offers a blend of performance, reliability, and versatility unmatched by traditional materials. My years in the industry reaffirm that understanding the environment, load requirements, and necessary regulatory compliance are key drivers for maximizing the efficacy of aluminum grating projects. Each step, from selection to installation, influences the outcome and value derived from aluminum grating, making these projects a worthwhile investment in both industrial and commercial settings.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024