- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 07, 2025 06:04

Back to list

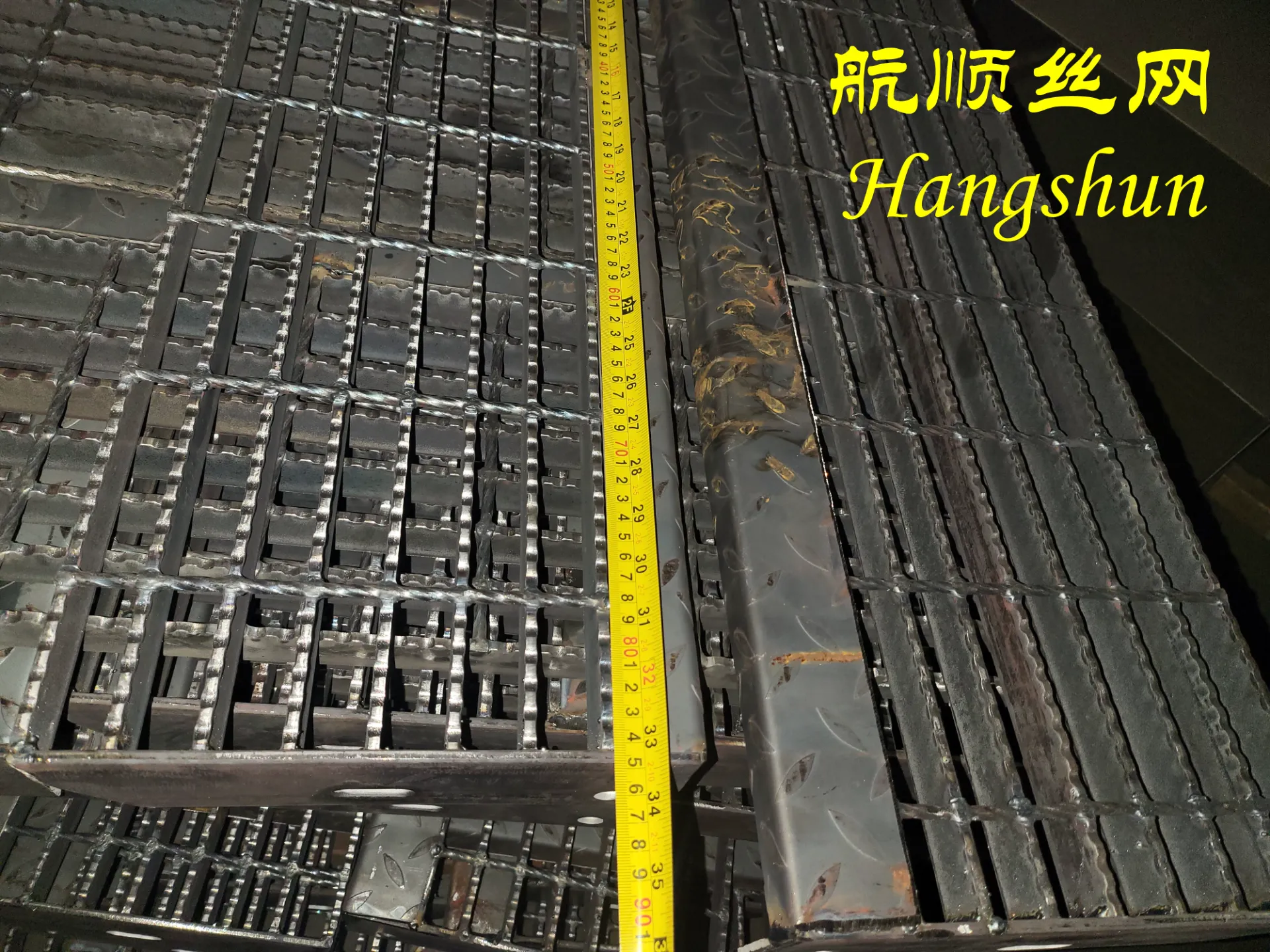

Steel Grating

Swage-locked grating is revolutionizing various industries by providing unparalleled strength, durability, and versatility. As industries continue to evolve, this type of grating becomes increasingly important for applications requiring robust and reliable materials. From architectural marvels to sustainable industrial solutions, swage-locked grating is quickly becoming the gold standard.

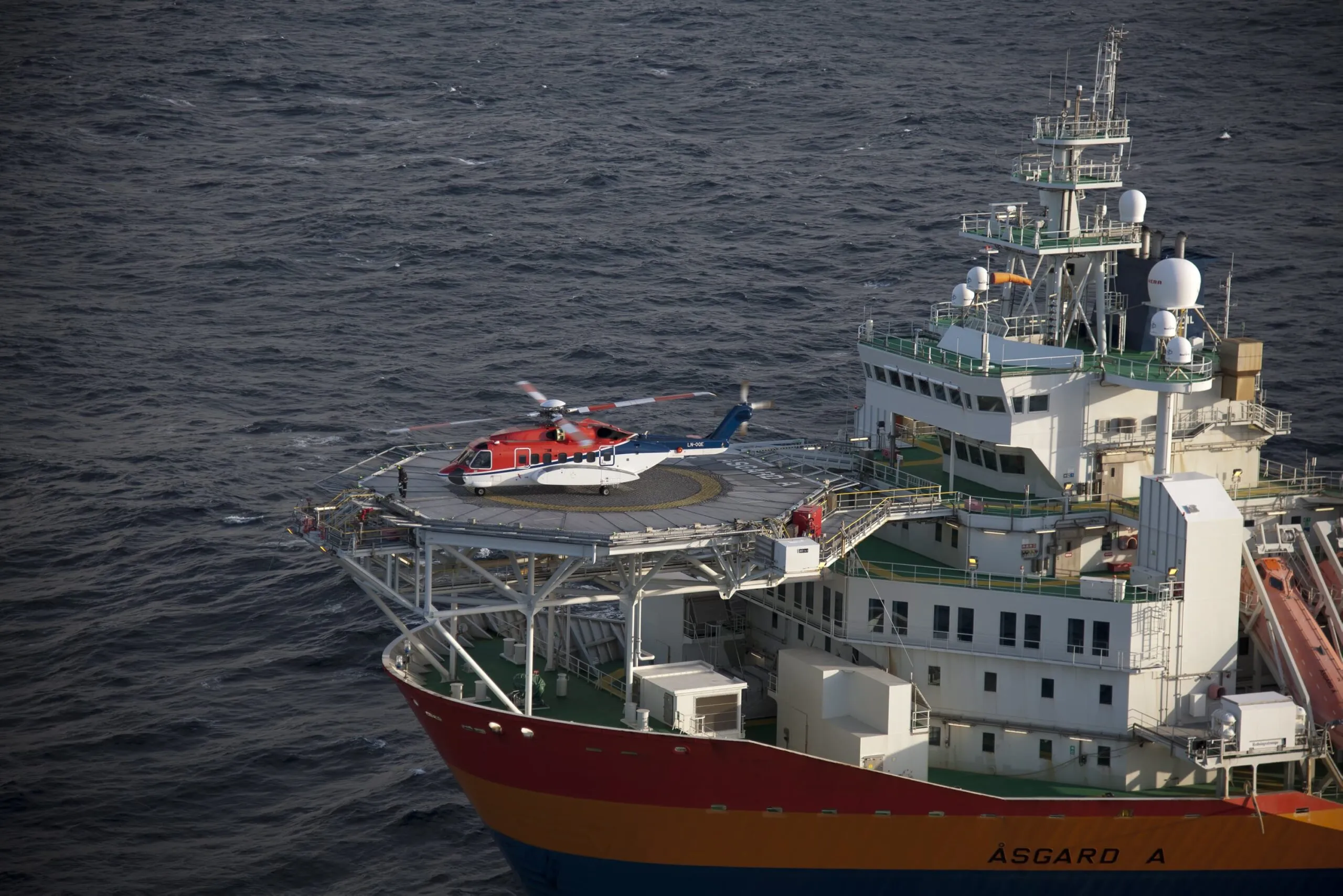

Trustworthiness in swage-locked grating is reinforced by the stringent quality control measures manufacturers adhere to. Industrial organizations often seek third-party certifications, ensuring every piece of grating meets or exceeds global standards. A prominent example involves a major chemical plant in Germany that adopted swage-locked grating for their new expansion, citing rigorous testing and quality assurance reports as critical factors in their decision-making process. Furthermore, swage-locked grating contributes to sustainability objectives by incorporating recycled materials during production. Its longevity and low maintenance requirements significantly reduce the need for frequent replacements, minimizing environmental impact and promoting sustainable building practices. Environmental engineers appreciate how its design reduces material waste and energy consumption, aligning with global efforts to promote sustainability in industrial operations. In terms of design flexibility, swage-locked grating can be customized to meet the specific needs of different projects. Whether it’s modifying the bar spacing for increased ventilation in a chemical plant or choosing materials that reduce heat absorption in a climate-sensitive architectural project, customization ensures that the grating meets precise operational needs. This adaptability aids in maintaining the structural integrity of various facilities, from metropolitan skyscrapers to remote energy installations. To sum up, swage-locked grating is facilitated by its innovative design, robust manufacturing process, and a commitment to quality and sustainability. Its broad-ranging applications across industries such as construction, oil and gas, and environmental engineering showcase its versatility and reliability. Professionals constantly vouch for its performance, making it a trusted ally in developing infrastructure that stands the test of time. As industries progress towards innovative solutions, swage-locked grating remains at the forefront, proving that a well-constructed framework is indispensable to modern advancements.

Trustworthiness in swage-locked grating is reinforced by the stringent quality control measures manufacturers adhere to. Industrial organizations often seek third-party certifications, ensuring every piece of grating meets or exceeds global standards. A prominent example involves a major chemical plant in Germany that adopted swage-locked grating for their new expansion, citing rigorous testing and quality assurance reports as critical factors in their decision-making process. Furthermore, swage-locked grating contributes to sustainability objectives by incorporating recycled materials during production. Its longevity and low maintenance requirements significantly reduce the need for frequent replacements, minimizing environmental impact and promoting sustainable building practices. Environmental engineers appreciate how its design reduces material waste and energy consumption, aligning with global efforts to promote sustainability in industrial operations. In terms of design flexibility, swage-locked grating can be customized to meet the specific needs of different projects. Whether it’s modifying the bar spacing for increased ventilation in a chemical plant or choosing materials that reduce heat absorption in a climate-sensitive architectural project, customization ensures that the grating meets precise operational needs. This adaptability aids in maintaining the structural integrity of various facilities, from metropolitan skyscrapers to remote energy installations. To sum up, swage-locked grating is facilitated by its innovative design, robust manufacturing process, and a commitment to quality and sustainability. Its broad-ranging applications across industries such as construction, oil and gas, and environmental engineering showcase its versatility and reliability. Professionals constantly vouch for its performance, making it a trusted ally in developing infrastructure that stands the test of time. As industries progress towards innovative solutions, swage-locked grating remains at the forefront, proving that a well-constructed framework is indispensable to modern advancements.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024