- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 07, 2025 06:38

Back to list

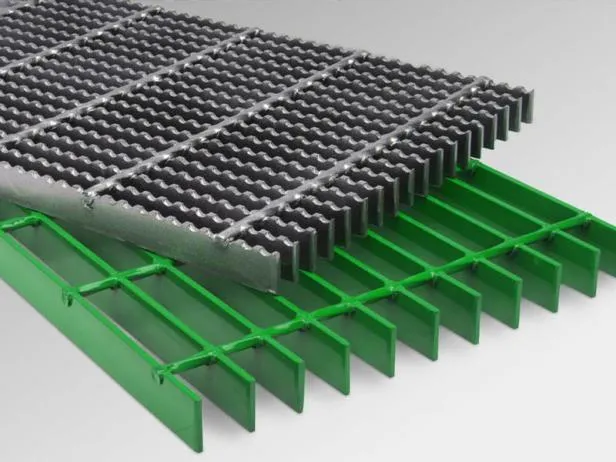

Steel Grating

Riveted grating, a robust and versatile product, has been at the forefront of industrial applications for decades. As industries evolve, the demand for durable and reliable materials like riveted grating has only increased, cementing its position as an indispensable component in various sectors, including construction, manufacturing, and transportation.

Notably, the authoritative nature of manufacturers producing riveted grating further amplifies its reliability. Companies that specialize in this product invest significantly in quality control measures, ensuring that every piece adheres to the strictest safety and performance standards. This dedication to quality imparts confidence in clients, knowing that their investments are protected by rigorous testing and certification processes. Case studies illustrate the trustworthiness of riveted grating. For instance, when renovating a century-old railway station, engineers opted for riveted grating to replace wooden decks. The outcome was transformative, providing a maintenance-free and sustainable solution that preserved the historical aesthetic while improving functionality. This testament to riveted grating's efficacy continues to attract new clients seeking long-term solutions for infrastructure projects. In terms of environmental sustainability, riveted grating offers several advantages. Since steel is one of the most recycled materials globally, utilizing riveted grating contributes to reducing the environmental footprint. Its longevity means less frequent replacements, thereby conserving raw materials and reducing waste over time. This aligns with global ambitions toward sustainability, making riveted grating not just an economic choice, but an environmentally responsible one. To conclude, riveted grating remains unmatched in delivering quality, safety, and cost-efficiency across various applications. Its robust nature, coupled with minimal maintenance requirements, offers peace of mind to project managers and company stakeholders. Moreover, its production by reputable manufacturers and alignment with sustainability goals further augments its standing as a top choice for industrial grating solutions. Riveted grating, with its impeccable track record and promising future, is poised to remain a cornerstone of industrial innovation and safety.

Notably, the authoritative nature of manufacturers producing riveted grating further amplifies its reliability. Companies that specialize in this product invest significantly in quality control measures, ensuring that every piece adheres to the strictest safety and performance standards. This dedication to quality imparts confidence in clients, knowing that their investments are protected by rigorous testing and certification processes. Case studies illustrate the trustworthiness of riveted grating. For instance, when renovating a century-old railway station, engineers opted for riveted grating to replace wooden decks. The outcome was transformative, providing a maintenance-free and sustainable solution that preserved the historical aesthetic while improving functionality. This testament to riveted grating's efficacy continues to attract new clients seeking long-term solutions for infrastructure projects. In terms of environmental sustainability, riveted grating offers several advantages. Since steel is one of the most recycled materials globally, utilizing riveted grating contributes to reducing the environmental footprint. Its longevity means less frequent replacements, thereby conserving raw materials and reducing waste over time. This aligns with global ambitions toward sustainability, making riveted grating not just an economic choice, but an environmentally responsible one. To conclude, riveted grating remains unmatched in delivering quality, safety, and cost-efficiency across various applications. Its robust nature, coupled with minimal maintenance requirements, offers peace of mind to project managers and company stakeholders. Moreover, its production by reputable manufacturers and alignment with sustainability goals further augments its standing as a top choice for industrial grating solutions. Riveted grating, with its impeccable track record and promising future, is poised to remain a cornerstone of industrial innovation and safety.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024