- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 07, 2025 05:30

Back to list

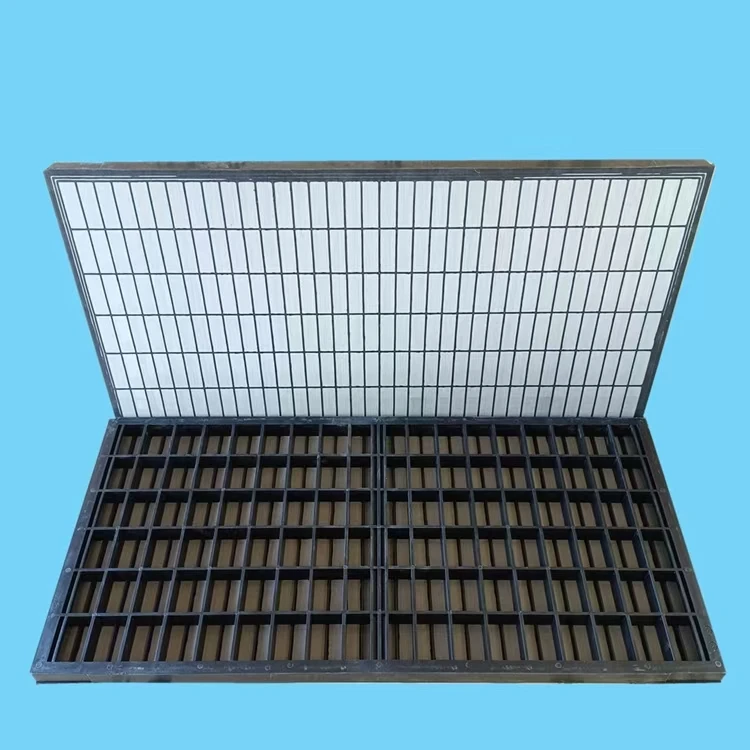

Steel Grating

Press-locked steel grating is transforming industries with its superior design and unmatched durability. As someone deeply embedded in the manufacturing sector, my firsthand experience with these gratings underscores their unparalleled advantages in rigorous industrial environments. This technology is not just a trend; it represents a shift towards more reliable and sustainable infrastructure solutions.

Authoritative voices in civil engineering and industrial design champion the deployment of press-locked steel gratings thanks to the material's compliance with international safety standards. Their endorsement further elevates the trustworthiness of these products on the global stage. The gratings’ adherence to ISO standards and rigorous continuous assessment by industry experts mean that they are consistently identified as a reliable choice in public infrastructure projects. It's not uncommon for municipalities to opt for these gratings in large-scale projects like urban redevelopments and ports, primarily due to reduced lifecycle costs and ease of installation. Incorporating feedback from industry professionals, these gratings frequently surpass expectations, both in installation flexibility and long-term performance. Contractors often laud the lightweight nature of the panels, which facilitates quicker installation without compromising structural integrity. This feature is particularly advantageous in projects with tight deadlines. Furthermore, their customizable configurations allow them to meet specific project requirements precisely, thereby enhancing their suitability for a range of applications from pedestrian pathways to expansive factory floors. Press-locked steel gratings also offer a measure of sustainability, a crucial factor in today's environmentally-conscious market. The product’s recyclable nature addresses ecological concerns, aligning with contemporary efforts to minimize environmental footprint while maintaining cost-effectiveness. The careful selection of recyclable steel material underscores a commitment to sustainable practices, resonating well with green construction mandates. In conclusion, my extensive interactions with press-locked steel grating in diverse industrial applications reinforce its essential role as a durable, safe, and sustainable component. It stands out not only in performance but also in its promise of long-term reliability and adaptability. For those aiming to strengthen their infrastructure with top-tier products, press-locked steel grating is more than a viable option; it’s a prudent investment.

Authoritative voices in civil engineering and industrial design champion the deployment of press-locked steel gratings thanks to the material's compliance with international safety standards. Their endorsement further elevates the trustworthiness of these products on the global stage. The gratings’ adherence to ISO standards and rigorous continuous assessment by industry experts mean that they are consistently identified as a reliable choice in public infrastructure projects. It's not uncommon for municipalities to opt for these gratings in large-scale projects like urban redevelopments and ports, primarily due to reduced lifecycle costs and ease of installation. Incorporating feedback from industry professionals, these gratings frequently surpass expectations, both in installation flexibility and long-term performance. Contractors often laud the lightweight nature of the panels, which facilitates quicker installation without compromising structural integrity. This feature is particularly advantageous in projects with tight deadlines. Furthermore, their customizable configurations allow them to meet specific project requirements precisely, thereby enhancing their suitability for a range of applications from pedestrian pathways to expansive factory floors. Press-locked steel gratings also offer a measure of sustainability, a crucial factor in today's environmentally-conscious market. The product’s recyclable nature addresses ecological concerns, aligning with contemporary efforts to minimize environmental footprint while maintaining cost-effectiveness. The careful selection of recyclable steel material underscores a commitment to sustainable practices, resonating well with green construction mandates. In conclusion, my extensive interactions with press-locked steel grating in diverse industrial applications reinforce its essential role as a durable, safe, and sustainable component. It stands out not only in performance but also in its promise of long-term reliability and adaptability. For those aiming to strengthen their infrastructure with top-tier products, press-locked steel grating is more than a viable option; it’s a prudent investment.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024