- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 07, 2025 04:58

Back to list

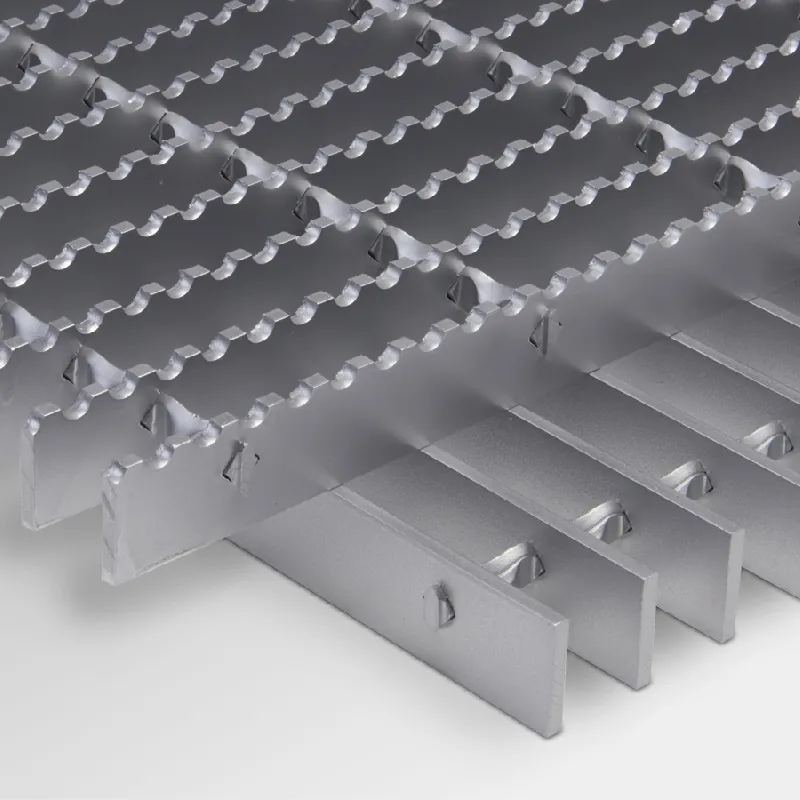

Welded Steel Grating

Heavy-duty welded bar grating is an indispensable component in various industrial applications where strength, durability, and safety are paramount. Its widespread use spans multiple sectors, from manufacturing facilities and warehouses to public infrastructure projects and offshore platforms. Understanding its benefits and applications can provide businesses with substantial advantages in optimizing their facilities for efficiency and safety.

Another significant advantage is its customization potential. Manufacturers can produce grating in a range of sizes, bar spacings, and finishes to meet specific application requirements. This level of customization ensures that industries can maintain design coherence and functionality across diverse operational platforms. Investing in high-quality welded bar grating also demonstrates a commitment to safety and regulatory compliance. With regulations increasingly focusing on workplace safety and environmental considerations, installing durable and efficient grating solutions can position a company as a leader in operational safety standards. Expertise in selecting the right grating involves understanding specific industrial needs, assessing environmental conditions, and evaluating load requirements. Consulting with specialists can ensure that the chosen grating solution not only meets practical demands but also elevates the facility's overall operational efficiency. Such consultation services are invaluable, particularly in complex projects where the interplay between structural integrity and industrial requirements is critical. Trustworthiness and authoritativeness in the use of heavy-duty welded bar grating come from collaborating with reputable manufacturers and suppliers. Companies with a track record of delivering quality products and abiding by rigorous manufacturing standards provide confidence to industry players. This assurance translates to lower life-cycle costs, fewer replacements, and sustainable facility management. In summary, heavy-duty welded bar grating offers a comprehensive solution for industries demanding strong, reliable, and low-maintenance flooring and structural support. Its adaptable nature, combined with outstanding load-bearing capabilities, makes it a preferred choice across diverse settings. Leveraging the unique benefits of welded bar grating can significantly enhance operational efficiency, uphold safety standards, and fortify infrastructure resilience.

Another significant advantage is its customization potential. Manufacturers can produce grating in a range of sizes, bar spacings, and finishes to meet specific application requirements. This level of customization ensures that industries can maintain design coherence and functionality across diverse operational platforms. Investing in high-quality welded bar grating also demonstrates a commitment to safety and regulatory compliance. With regulations increasingly focusing on workplace safety and environmental considerations, installing durable and efficient grating solutions can position a company as a leader in operational safety standards. Expertise in selecting the right grating involves understanding specific industrial needs, assessing environmental conditions, and evaluating load requirements. Consulting with specialists can ensure that the chosen grating solution not only meets practical demands but also elevates the facility's overall operational efficiency. Such consultation services are invaluable, particularly in complex projects where the interplay between structural integrity and industrial requirements is critical. Trustworthiness and authoritativeness in the use of heavy-duty welded bar grating come from collaborating with reputable manufacturers and suppliers. Companies with a track record of delivering quality products and abiding by rigorous manufacturing standards provide confidence to industry players. This assurance translates to lower life-cycle costs, fewer replacements, and sustainable facility management. In summary, heavy-duty welded bar grating offers a comprehensive solution for industries demanding strong, reliable, and low-maintenance flooring and structural support. Its adaptable nature, combined with outstanding load-bearing capabilities, makes it a preferred choice across diverse settings. Leveraging the unique benefits of welded bar grating can significantly enhance operational efficiency, uphold safety standards, and fortify infrastructure resilience.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024