- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

steel pipe winding mesh

Steel pipe winding mesh is a crucial advancement in the realm of construction and manufacturing, offering unprecedented flexibility and strength in industrial applications. The precision and durability of this product make it a go-to solution for various engineering challenges, from fluid transportation to structural reinforcement. This sophisticated innovation stems from decades of expertise in metallurgy and materials science, ensuring its reliability and efficiency in diverse environments.

In the intricate world of construction, the applications of steel pipe winding mesh are broad and varied, primarily due to its robust nature and adaptable structure. It is commonly employed in the reinforcement of concrete structures, serving as a backbone that significantly enhances the tensile strength and load-bearing capacity of buildings, bridges, and roadways. This is particularly valuable in regions prone to seismic activity, where structural integrity is paramount. The interlocked mesh design evenly distributes stress across surfaces, reducing the risk of cracking or failure under pressure.

From an expert perspective, the manufacturing process of steel pipe winding mesh is a fine dance of precision equipment and highly developed techniques. The steel used is typically of high tensile grade, processed under stringent quality controls to ensure consistency in performance. This attention to detail is not just confined to the materials, but extends to the winding process itself—the angles and tension employed during winding are calculated with exactitude to maximize durability without compromising on flexibility.

In industrial fluid handling, steel pipe winding mesh offers a unique benefit—corrosion resistance. Given the nature of many fluids transported in industrial settings, including corrosive chemicals and high-temperature substances, materials that can withstand such conditions without degrading are essential. This product is frequently coated with specialized additives that enhance its resistance to oxidation and environmental wear, ensuring longevity in harsh operating conditions.

steel pipe winding mesh

This level of expert-driven manufacturing ensures that each mesh can withstand both environmental and operational stresses, positioning it as an authoritative choice in the market. Customers who choose steel pipe winding mesh are assured of its efficacy and longevity, thus reinforcing the product's trustworthiness. This is borne out by numerous case studies that illustrate its successful application in high-stakes projects across the globe.

In sum, steel pipe winding mesh is a well-engineered solution tailored to meet modern industrial demands. Its combination of strength, adaptability, and resistance to wear meets the needs of builders, engineers, and manufacturers who require reliable and durable materials. As infrastructure continues to evolve, the role of such advanced materials becomes ever more critical, underlining the import of selecting components that have been developed under the guiding principles of safety, durability, and precision.

By integrating real-world experiences and expert insights, the enhanced qualities of steel pipe winding mesh become self-evident, aligning it firmly as a cornerstone in next-generation infrastructure projects.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

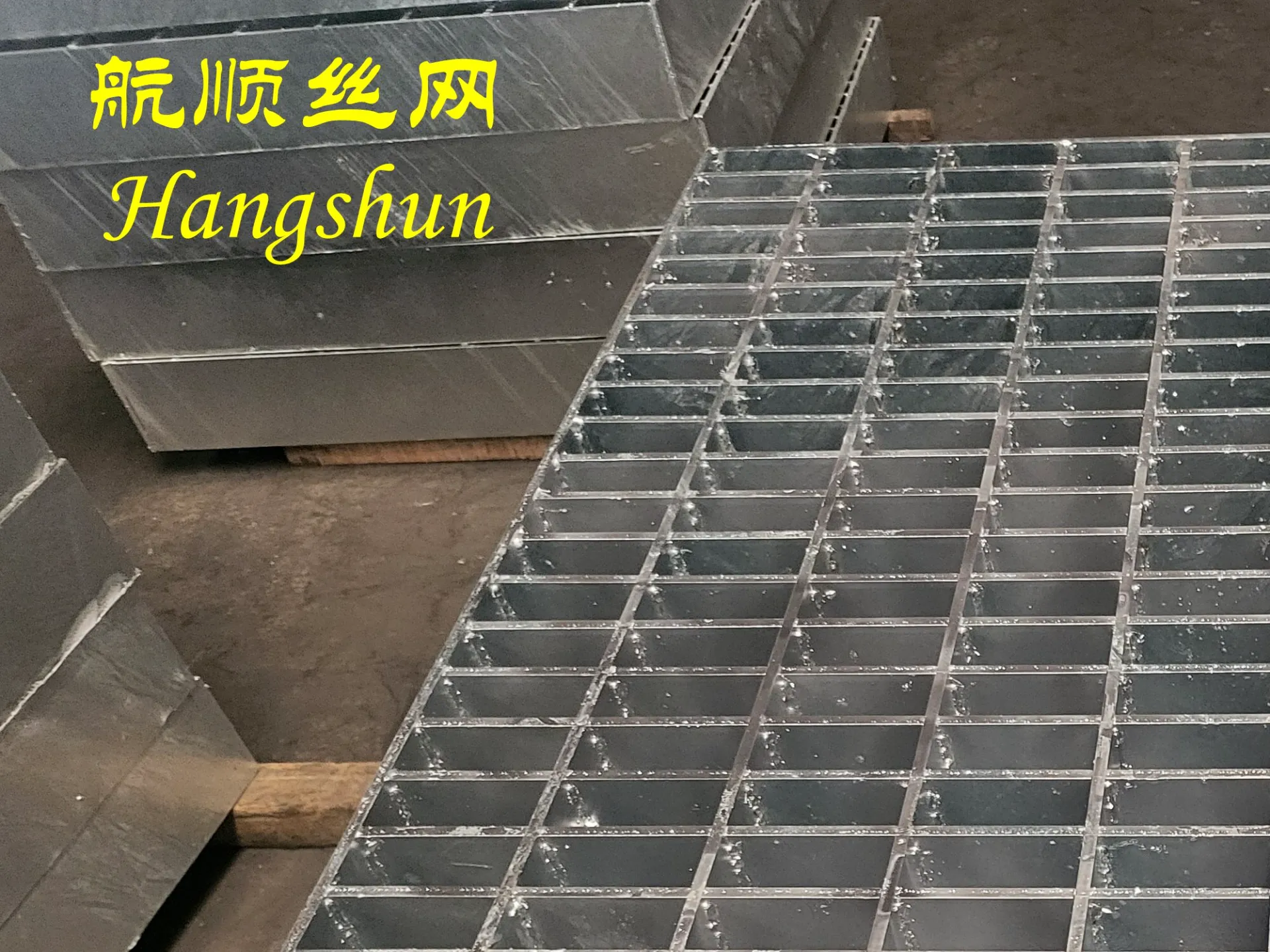

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024