- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

concrete weight coating mesh

Concrete weight coating mesh plays a pivotal role in the integrity and longevity of pipeline systems

, particularly in underwater projects. This specialized mesh is integral to the concrete weighting process, providing stability and protection to pipelines. The demand for expertise in concrete weight coating mesh is higher than ever, driven by an increase in global infrastructure projects and energy demands.

Drawing from years of experience in the construction and energy sectors, concrete weight coating mesh is more than just a structural component. It's a blend of engineering precision and material science, geared towards enhancing the efficacy of pipelines in challenging environments. Expertise in it ensures that pipelines not only stay grounded against powerful ocean currents but also remain protected against the harsh conditions of the seabed.

In-depth knowledge about the properties of the mesh is critical for project success. Typically made from high-strength steel or corrosion-resistant alloys, the mesh is integral to maintaining a strong bond with the concrete, which helps in achieving the desired pipeline buoyancy and stability. This expertise ensures that projects are executed correctly the first time, saving both time and resources while minimizing potential risks.

This knowledge extends to recognizing the diverse applications and specifications of the mesh. For instance, not all underwater pipelines have the same requirements. Parameters such as water depth, current strength, and seabed conditions influence the mesh design and composition. Thus, an authoritative understanding of these factors contributes to the selection of the appropriate mesh, impacting the project’s overall success.

concrete weight coating mesh

Furthermore, it’s important to recognize the trustworthiness of the sources of this material. Industry leaders prioritize suppliers who consistently deliver quality materials that meet rigorous safety and environmental standards. This reliability is key, as even a minor flaw in the mesh can lead to significant project delays and increased costs.

Trust is also built through transparency and certification of the mesh used. Reputable manufacturers often provide comprehensive data sheets and test results, ensuring that each batch delivered meets industry standards for strength, elasticity, and durability. These documents serve as a testament to the product's performance capabilities, reinforcing confidence in its use.

Moreover, real-world experience highlights the importance of proper installation techniques. Even the highest quality mesh can be compromised if not applied correctly. Technicians and engineers with hands-on experience understand the subtleties of mesh handling and concrete pouring, ensuring the protective layer functions as intended.

In conclusion, concrete weight coating mesh is a critical component in pipeline projects, demanding a thorough understanding of materials and application. Those in the industry leverage extensive experience, authoritative knowledge, and a keen eye for trustworthy sources to implement these solutions effectively. As infrastructure needs grow, the role of concrete weight coating mesh will continue to be indispensable, requiring ongoing learning and adaptation to new technological advances and environmental challenges.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

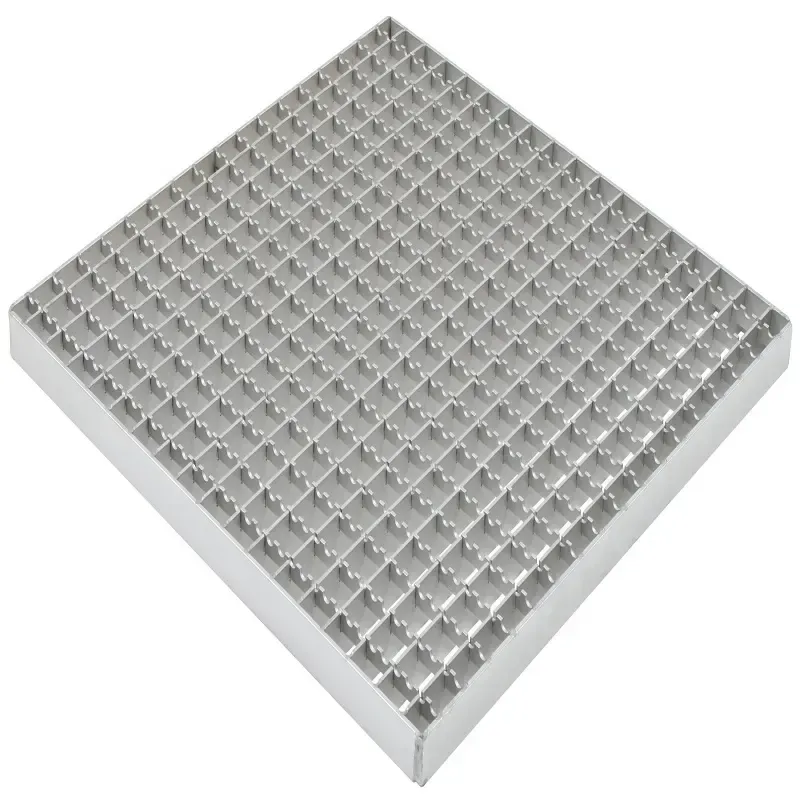

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024