- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 01, 2025 06:03

Back to list

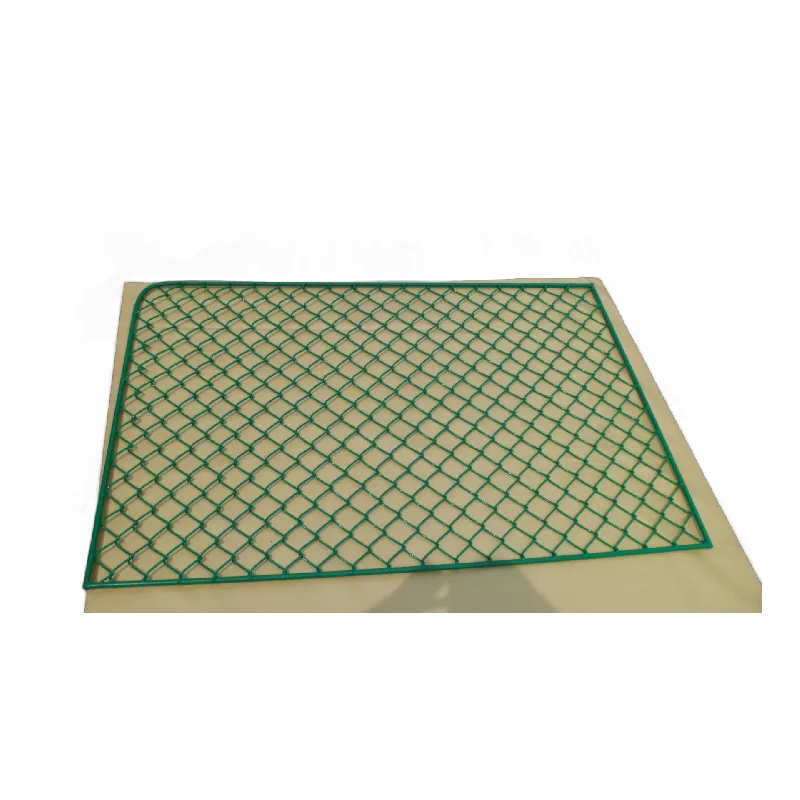

Welded Steel Grating

Understanding the weight of steel bar grating is essential when considering its application in various construction and industrial projects. It's a factor that goes beyond mere numbers, influencing design choices, budget allocations, and ultimately the structural integrity of projects. Whether you're a contractor, architect, or procurement officer, mastering this concept ensures informed decision-making in alignment with industry best practices.

Experts often emphasize the distinction between standard and custom gratings. While standard panels are cost-effective and readily available, custom gratings can be tailored to minimize waste and ensure optimal weight and strength attributes. This customization enhances safety and compliance with project specifications. Beyond the physical properties, selecting the appropriate finish for steel bar gratings impacts weight and longevity. Hot-dip galvanizing adds weight but provides superior corrosion resistance—a critical consideration in outdoor or chemically exposed environments. Stainless steel offers a naturally appealing finish and inherent resistance to oxidation, thus avoiding additional weight from coatings. The reliability of weight specifications also speaks to the credibility of suppliers. Trustworthy suppliers adhere to rigorous manufacturing standards and provide detailed weight metrics in their product listings or datasheets, ensuring transparency in communication. This reliability is instrumental when comparing quotes or drafting contracts, eliminating unforeseen costs associated with incorrect weight estimations. Investing in professional advice from structural engineers or materials experts is advisable when dealing with complex load requirements. These professionals can provide insights into weight distribution, structural analysis, and the economic implications of different grating choices, thereby enhancing project efficiency and safety. In conclusion, the weight of steel bar grating is not merely a specification but a pivotal element influencing design, safety, and cost. By understanding the intricacies of grating weight—leveraging expert advice, precise calculations, and quality suppliers—industry professionals can enhance project outcomes, ensuring resilience and profitability in a competitive market.

Experts often emphasize the distinction between standard and custom gratings. While standard panels are cost-effective and readily available, custom gratings can be tailored to minimize waste and ensure optimal weight and strength attributes. This customization enhances safety and compliance with project specifications. Beyond the physical properties, selecting the appropriate finish for steel bar gratings impacts weight and longevity. Hot-dip galvanizing adds weight but provides superior corrosion resistance—a critical consideration in outdoor or chemically exposed environments. Stainless steel offers a naturally appealing finish and inherent resistance to oxidation, thus avoiding additional weight from coatings. The reliability of weight specifications also speaks to the credibility of suppliers. Trustworthy suppliers adhere to rigorous manufacturing standards and provide detailed weight metrics in their product listings or datasheets, ensuring transparency in communication. This reliability is instrumental when comparing quotes or drafting contracts, eliminating unforeseen costs associated with incorrect weight estimations. Investing in professional advice from structural engineers or materials experts is advisable when dealing with complex load requirements. These professionals can provide insights into weight distribution, structural analysis, and the economic implications of different grating choices, thereby enhancing project efficiency and safety. In conclusion, the weight of steel bar grating is not merely a specification but a pivotal element influencing design, safety, and cost. By understanding the intricacies of grating weight—leveraging expert advice, precise calculations, and quality suppliers—industry professionals can enhance project outcomes, ensuring resilience and profitability in a competitive market.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024