- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 30, 2025 01:18

Back to list

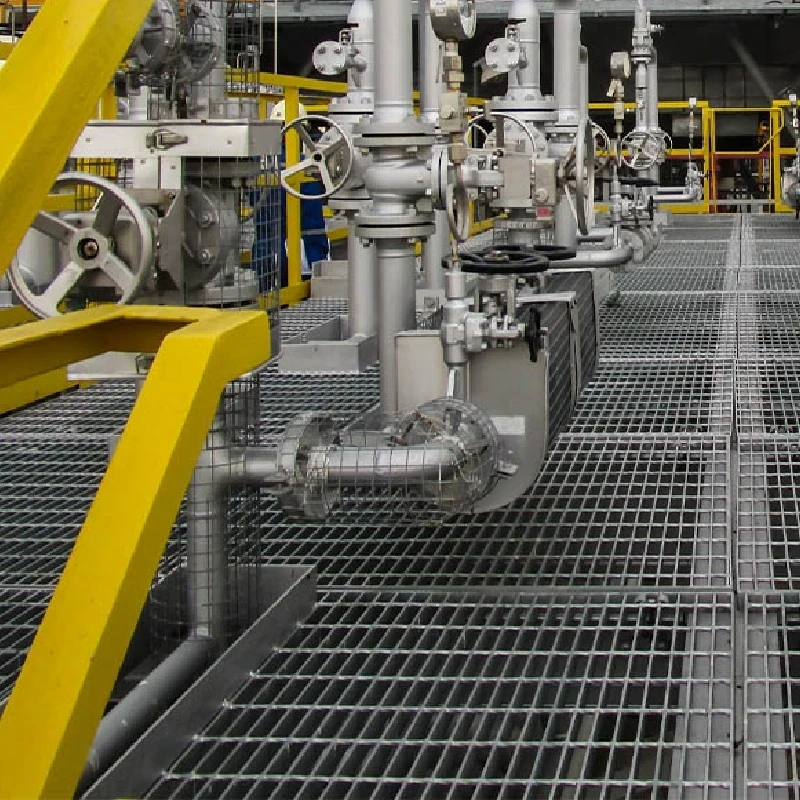

steel bar grating sizes

In the world of construction and manufacturing, steel bar grating is an essential component, serving as a staple in walkways, platforms, and safety barriers. Its robust structure and versatility make it a preferred choice for many architects and engineers. To optimize any project involving steel bar gratings, understanding the various sizes available and their applications is key.

Quality manufacturing processes are intrinsic to the reliability and durability of steel bar gratings. Reputable manufacturers adopt advanced pressure locking systems and weld forging techniques, ensuring that each intersection of the bearing and cross bars is securely bonded. This not only extends the lifespan of the grating but also enhances its load-bearing capacity. Professionals in the field consistently recommend sourcing grating from certified suppliers to guarantee compliance with industry standards and specifications. Beyond standard specifications, custom fabrication options are available to fit unique project demands. Customization can include specialty coatings for enhanced corrosion resistance, specific walk surface modifications for improved traction, and color coding for safety zones. These adaptations make steel bar grating highly adaptable, adding both functional and aesthetic value to infrastructures. Implementing the correct size and type of steel bar grating is instrumental in ensuring project success. For specialists in architecture and construction, the right selection contributes significantly to the durability and efficiency of the structures they design. Balancing load requirements, aesthetic considerations, and environmental factors are best managed by consulting with grating specialists who provide guidance based on real-world experience and industry knowledge. When selecting steel bar grating for a project, weighing factors such as load-bearing needs, environmental conditions, safety requirements, and installation logistics is crucial. Expertise-driven decisions not only align with best practices in engineering but also foster trust with clients by delivering robust and reliable infrastructure solutions. Having an authoritative grasp on the implications of various grating sizes allows professionals to make informed decisions that align with both safety and budgetary constraints. Experience shows that proper sizing and selection can lead to significant long-term advantages, including reduced maintenance costs and increased structural performance. Thus, understanding the nuances of steel bar grating sizes delivers a powerful impact on the ultimate success and integrity of construction projects.

Quality manufacturing processes are intrinsic to the reliability and durability of steel bar gratings. Reputable manufacturers adopt advanced pressure locking systems and weld forging techniques, ensuring that each intersection of the bearing and cross bars is securely bonded. This not only extends the lifespan of the grating but also enhances its load-bearing capacity. Professionals in the field consistently recommend sourcing grating from certified suppliers to guarantee compliance with industry standards and specifications. Beyond standard specifications, custom fabrication options are available to fit unique project demands. Customization can include specialty coatings for enhanced corrosion resistance, specific walk surface modifications for improved traction, and color coding for safety zones. These adaptations make steel bar grating highly adaptable, adding both functional and aesthetic value to infrastructures. Implementing the correct size and type of steel bar grating is instrumental in ensuring project success. For specialists in architecture and construction, the right selection contributes significantly to the durability and efficiency of the structures they design. Balancing load requirements, aesthetic considerations, and environmental factors are best managed by consulting with grating specialists who provide guidance based on real-world experience and industry knowledge. When selecting steel bar grating for a project, weighing factors such as load-bearing needs, environmental conditions, safety requirements, and installation logistics is crucial. Expertise-driven decisions not only align with best practices in engineering but also foster trust with clients by delivering robust and reliable infrastructure solutions. Having an authoritative grasp on the implications of various grating sizes allows professionals to make informed decisions that align with both safety and budgetary constraints. Experience shows that proper sizing and selection can lead to significant long-term advantages, including reduced maintenance costs and increased structural performance. Thus, understanding the nuances of steel bar grating sizes delivers a powerful impact on the ultimate success and integrity of construction projects.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024