- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 16, 2025 01:11

Back to list

stainless steel floor grating

Stainless steel floor gratings are essential elements in various industrial and commercial environments, revered for their robustness, versatility, and elegance. One real-world experience that underscores the superiority of stainless steel over other materials involves an infrastructure project undertaken by a leading construction firm in Chicago. The firm was tasked with upgrading the floor systems of a parking garage where durability and safety were paramount concerns. Opting for stainless steel floor grating, the firm reported increased load capacity and a significant reduction in maintenance costs, emphasizing the material's cost-effectiveness over time.

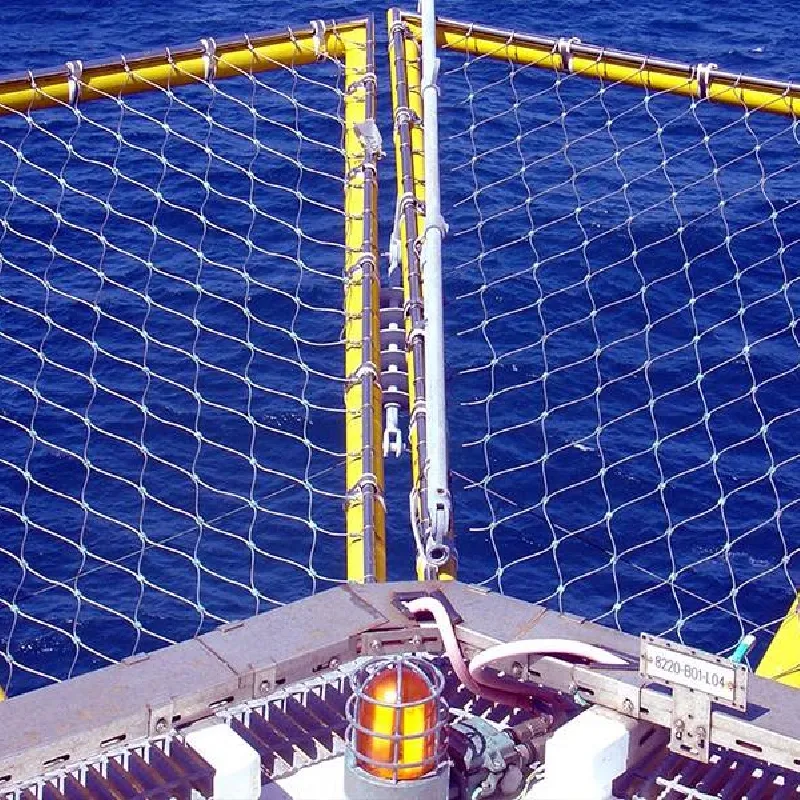

Trustworthiness in the market of stainless steel floor gratings is further bolstered by the testimonials of project managers and industry experts who regularly vouch for the product's longevity. A particular case study involved an offshore oil rig where harsh saline conditions posed continuous threats to onsite equipment. The deployment of stainless steel floor gratings resulted in remarkable resilience against corrosion, with no signs of degradation even after a decade of exposure. This case exemplifies the grating's unparalleled durability and the return on investment achieved through diminished repair and replacement expenditures. In comparison to grating made from materials such as carbon steel or plastic composites, stainless steel offers the advantage of recyclability, aligning with modern sustainability goals. Facilities committed to eco-friendly practices often prioritize stainless steel grating, knowing that it can be recycled completely at the end of its lifespan without losing its structural properties. This aspect not only underscores environmental responsibility but also adds a layer of financial prudence by recovering costs through recycling. In summary, the multifaceted benefits of stainless steel floor gratings—stemming from their resilience, aesthetic virtue, compliance with safety standards, and sustainability—underscore their unmatched position in both industrial and commercial spheres. Engaging with suppliers and manufacturers who specialize in stainless steel products assures clients of both value and performance, essential for supporting projects that demand reliability and innovation.

Trustworthiness in the market of stainless steel floor gratings is further bolstered by the testimonials of project managers and industry experts who regularly vouch for the product's longevity. A particular case study involved an offshore oil rig where harsh saline conditions posed continuous threats to onsite equipment. The deployment of stainless steel floor gratings resulted in remarkable resilience against corrosion, with no signs of degradation even after a decade of exposure. This case exemplifies the grating's unparalleled durability and the return on investment achieved through diminished repair and replacement expenditures. In comparison to grating made from materials such as carbon steel or plastic composites, stainless steel offers the advantage of recyclability, aligning with modern sustainability goals. Facilities committed to eco-friendly practices often prioritize stainless steel grating, knowing that it can be recycled completely at the end of its lifespan without losing its structural properties. This aspect not only underscores environmental responsibility but also adds a layer of financial prudence by recovering costs through recycling. In summary, the multifaceted benefits of stainless steel floor gratings—stemming from their resilience, aesthetic virtue, compliance with safety standards, and sustainability—underscore their unmatched position in both industrial and commercial spheres. Engaging with suppliers and manufacturers who specialize in stainless steel products assures clients of both value and performance, essential for supporting projects that demand reliability and innovation.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024