- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 16, 2025 01:32

Back to list

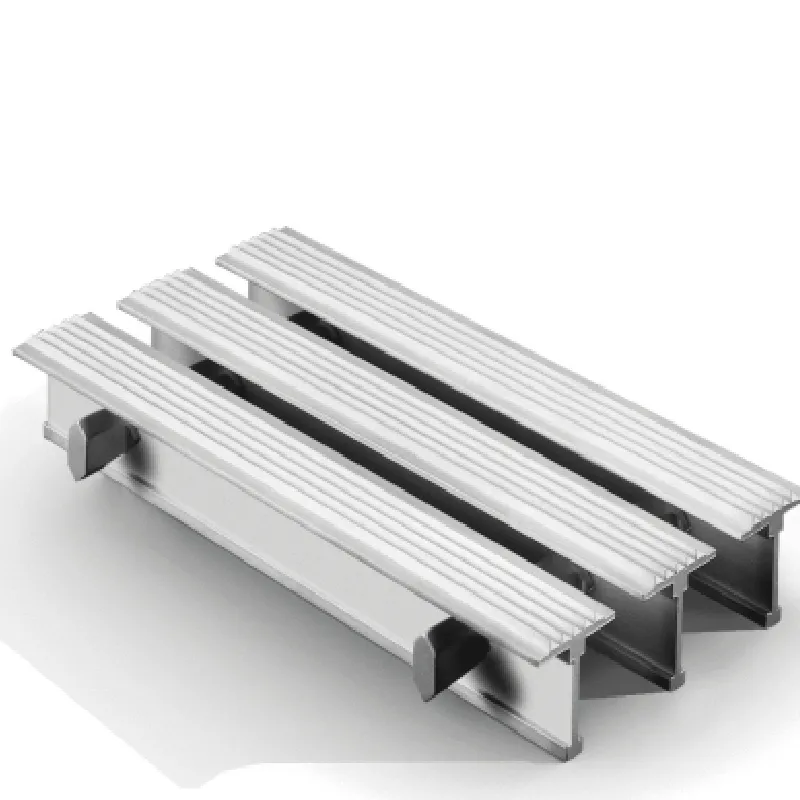

heavy duty steel grating price

When it comes to industrial and commercial applications, heavy duty steel grating plays a vital role in ensuring durability, safety, and performance. Understanding the pricing factors associated with this essential product is crucial for architects, builders, and project managers committed to making cost-effective decisions without compromising quality.

Trustworthiness in sourcing steel grating cannot be overstated. Partnering with reputable manufacturers or suppliers, known for meeting industry standards such as ISO 90012015 for quality management, ensures that the product is not only fairly priced but also reliable in performance. Suppliers who offer transparent pricing structures, detailed product specifications, and robust customer support allow for informed purchasing decisions that align with project requirements. Additionally, market trends and economic factors such as global steel demand, tariffs, and transportation costs must be considered when analyzing heavy duty steel grating prices. The fluctuating global economy can impact steel prices significantly; thus, having insights into market dynamics can be beneficial for budgeting and planning. In conclusion, understanding heavy duty steel grating pricing involves a multidimensional approach encompassing material quality, manufacturing techniques, technical specifications, and market conditions. By focusing on these elements, professionals can optimize their use of steel grating in various applications, ensuring that they receive the best value for their investment. Expertise in these areas guarantees projects that are not only economically sound but also structurally robust and compliant with safety standards.

Trustworthiness in sourcing steel grating cannot be overstated. Partnering with reputable manufacturers or suppliers, known for meeting industry standards such as ISO 90012015 for quality management, ensures that the product is not only fairly priced but also reliable in performance. Suppliers who offer transparent pricing structures, detailed product specifications, and robust customer support allow for informed purchasing decisions that align with project requirements. Additionally, market trends and economic factors such as global steel demand, tariffs, and transportation costs must be considered when analyzing heavy duty steel grating prices. The fluctuating global economy can impact steel prices significantly; thus, having insights into market dynamics can be beneficial for budgeting and planning. In conclusion, understanding heavy duty steel grating pricing involves a multidimensional approach encompassing material quality, manufacturing techniques, technical specifications, and market conditions. By focusing on these elements, professionals can optimize their use of steel grating in various applications, ensuring that they receive the best value for their investment. Expertise in these areas guarantees projects that are not only economically sound but also structurally robust and compliant with safety standards.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024