- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 16, 2025 01:50

Back to list

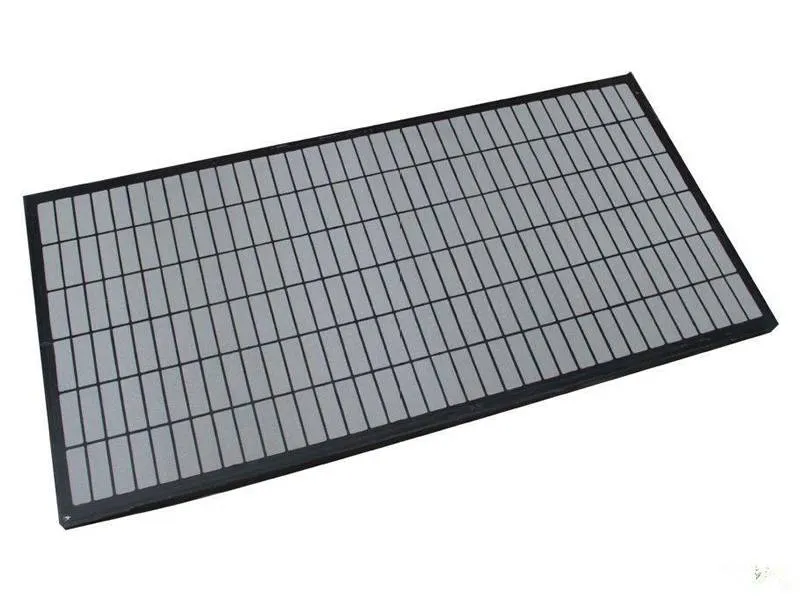

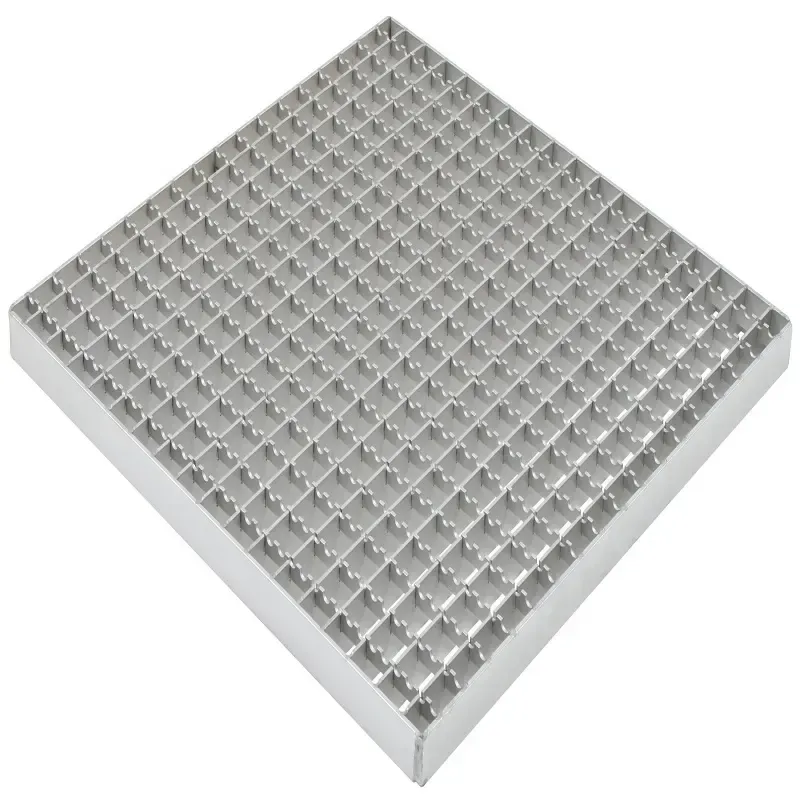

galvanized grating price

Understanding the price dynamics of galvanized grating involves more than just scanning a spreadsheet or pulling up a price quote. It encompasses the intricate interplay between material quality, market demand, manufacturing processes, and additional influencing factors such as labor and transportation costs. For anyone in the construction or manufacturing industries, having an awareness of these elements is crucial for making informed purchasing decisions.

Market Demand and Supply The fluctuating forces of supply and demand vitally affect galvanized grating prices. In periods of high construction activity, demand for durable materials like galvanized grating multiplies, leading to price surges. Conversely, a downturn in demand or oversupply in the market can drive costs down. Factors such as global economic health, seasonality, and industry trends are all key players in these shifts. Additional Costs Beyond manufacturing, transportation costs considerably influence pricing. Steel grating is typically heavy and bulky, making shipping an appreciable portion of the purchase cost. Buyers should also consider labor costs for installation; opting for a more durable, expensive grade may reduce labor time and costs, balancing out the upfront investment. Conclusion Purchasing galvanized grating requires a discerning approach, balancing initial costs with long-term benefits. Those who recognize the importance of quality materials, familiar manufacturing processes, current market conditions, and additional logistical expenses can make smarter choices. Insight and expertise in this domain ensure not only fiscal prudence but also contribute to successful project outcomes, enhancing overall structural integrity and safety. As with any strategic business decision, staying informed through various expert resources and periodic market analysis remains crucial for staying ahead in the competitive landscape of construction and manufacturing industries.

Market Demand and Supply The fluctuating forces of supply and demand vitally affect galvanized grating prices. In periods of high construction activity, demand for durable materials like galvanized grating multiplies, leading to price surges. Conversely, a downturn in demand or oversupply in the market can drive costs down. Factors such as global economic health, seasonality, and industry trends are all key players in these shifts. Additional Costs Beyond manufacturing, transportation costs considerably influence pricing. Steel grating is typically heavy and bulky, making shipping an appreciable portion of the purchase cost. Buyers should also consider labor costs for installation; opting for a more durable, expensive grade may reduce labor time and costs, balancing out the upfront investment. Conclusion Purchasing galvanized grating requires a discerning approach, balancing initial costs with long-term benefits. Those who recognize the importance of quality materials, familiar manufacturing processes, current market conditions, and additional logistical expenses can make smarter choices. Insight and expertise in this domain ensure not only fiscal prudence but also contribute to successful project outcomes, enhancing overall structural integrity and safety. As with any strategic business decision, staying informed through various expert resources and periodic market analysis remains crucial for staying ahead in the competitive landscape of construction and manufacturing industries.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024