- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 02:05

Back to list

shale shaker screen for sale

Finding the right shale shaker screen for sale can be a challenging endeavor, especially for those who lack firsthand experience in the oil and gas industry. As the industry's reliance on efficient drilling technology continues to grow, the significance of high-quality shaker screens cannot be overstated. This article aims to provide an in-depth and professional look into the practicalities of purchasing shale shaker screens, drawing from real experiences and insights from industry experts.

Building trust with suppliers can also be beneficial; establishing a direct line with manufacturers or authorized distributors guarantees access to genuine products and necessary support. Verified sellers not only ensure that the product supplied is of high quality but also provide necessary certifications and compliance with industry standards. Moreover, digital platforms have become an indispensable tool for sourcing shaker screens globally. Trusted online marketplaces provide a catalog of numerous options, allowing buyers to compare products effectively. Engaging with digital communities and forums can further enhance one's understanding and help narrow down choices based on firsthand information shared by field experts. To conclude, purchasing the right shale shaker screen requires a blend of technical insight, peer advice, and supplier transparency. Investing time in research and relying on industry expertise can lead to smarter purchasing decisions, ultimately culminating in more efficient and cost-effective drilling operations. When searching for shale shaker screens for sale, keep these considerations in mind to ensure that your selection contributes positively to your drilling project's success. Each screen's performance is a critical cog in the overall machinery of drilling operations, affecting everything from operational efficiency to equipment maintenance cycles. For anyone serious about optimizing their drilling processes, taking the time to understand these factors and leveraging expert insights will ensure a reliable and effective solids control strategy that stands the test of time.

Building trust with suppliers can also be beneficial; establishing a direct line with manufacturers or authorized distributors guarantees access to genuine products and necessary support. Verified sellers not only ensure that the product supplied is of high quality but also provide necessary certifications and compliance with industry standards. Moreover, digital platforms have become an indispensable tool for sourcing shaker screens globally. Trusted online marketplaces provide a catalog of numerous options, allowing buyers to compare products effectively. Engaging with digital communities and forums can further enhance one's understanding and help narrow down choices based on firsthand information shared by field experts. To conclude, purchasing the right shale shaker screen requires a blend of technical insight, peer advice, and supplier transparency. Investing time in research and relying on industry expertise can lead to smarter purchasing decisions, ultimately culminating in more efficient and cost-effective drilling operations. When searching for shale shaker screens for sale, keep these considerations in mind to ensure that your selection contributes positively to your drilling project's success. Each screen's performance is a critical cog in the overall machinery of drilling operations, affecting everything from operational efficiency to equipment maintenance cycles. For anyone serious about optimizing their drilling processes, taking the time to understand these factors and leveraging expert insights will ensure a reliable and effective solids control strategy that stands the test of time.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

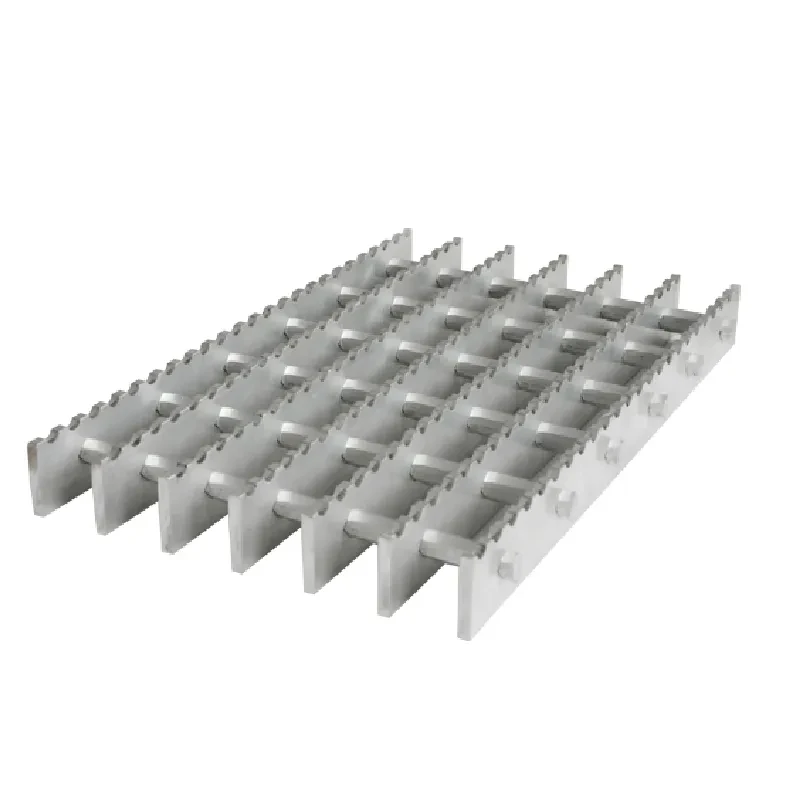

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024