- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 01:29

Back to list

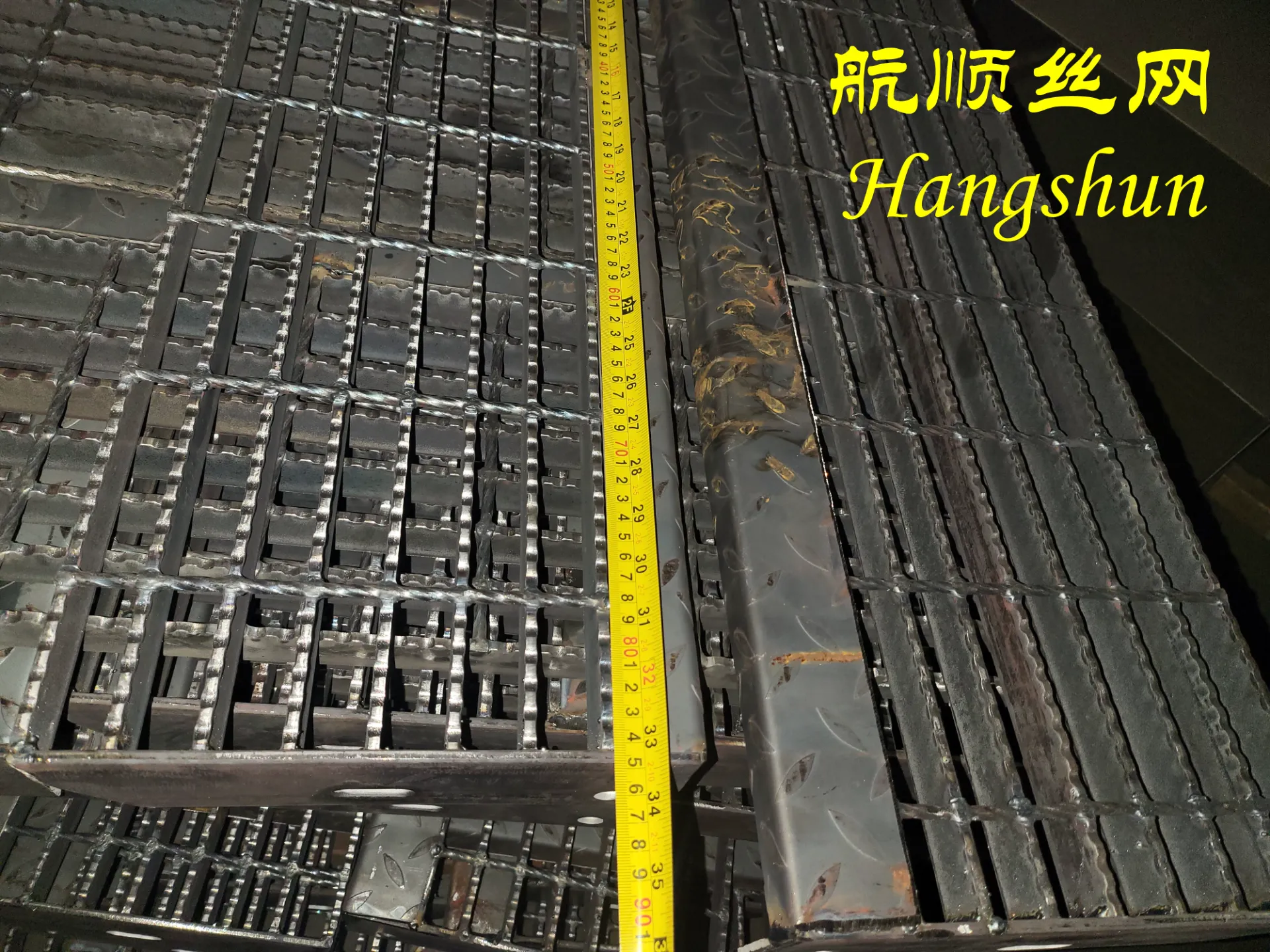

shale shaker screens for sale

Finding the right shale shaker screens for sale can have an unparalleled impact on operations in the oil and gas industry. These screens are fundamental components in the drilling process, designed to filter and separate solids from drilling fluid—a crucial step in ensuring optimal performance of drilling equipment. Expertise in selecting the appropriate shale shaker screen requires an understanding not only of the available types but also of the specific needs of your operation.

Moreover, industry expertise suggests that aligning screen selection with the specifications of your shaker model is not just beneficial but necessary. Manufacturers typically design screens that best fit their specific shakers, and using the original equipment manufacturer's (OEM) screens can ensure the best fit and function, leading to improved durability and operational efficiency. Furthermore, feedback from diverse operational environments worldwide highlights the necessity of customization. The one-size-fits-all approach often falls short in this context. Working closely with manufacturers to design custom screens tailored for particular environmental conditions or unique operational requirements could lead to competitive advantages, including cost reductions and improved performance metrics. Finally, the dynamic nature of the oil and gas sector demands that professionals stay informed of technological advances and emerging trends in screen technology. Participating in industry forums, subscribing to relevant publications, or engaging in workshops can enhance knowledge and application techniques. Today, innovative solutions are setting new standards across the industry. For instance, hybrid screen technology is integrating the strengths of different screen types to enhance fluid handling capacity while minimizing the risks of screen damage. Continuous learning and adaptation, supported by a wealth of real-world experience, can prepare operators to make informed decisions that optimize drilling operations. In conclusion, the right selection and use of shale shaker screens hinge on a balanced consideration of technical specifications, certification standards, and field experience. Expertise and an authoritative approach are pivotal, rooted in an unwavering commitment to quality and trustworthiness. Adopting these principles will undoubtedly lead to more efficient, effective, and economical drilling operations, underscoring both the art and science that characterize this essential sector of the oil and gas industry.

Moreover, industry expertise suggests that aligning screen selection with the specifications of your shaker model is not just beneficial but necessary. Manufacturers typically design screens that best fit their specific shakers, and using the original equipment manufacturer's (OEM) screens can ensure the best fit and function, leading to improved durability and operational efficiency. Furthermore, feedback from diverse operational environments worldwide highlights the necessity of customization. The one-size-fits-all approach often falls short in this context. Working closely with manufacturers to design custom screens tailored for particular environmental conditions or unique operational requirements could lead to competitive advantages, including cost reductions and improved performance metrics. Finally, the dynamic nature of the oil and gas sector demands that professionals stay informed of technological advances and emerging trends in screen technology. Participating in industry forums, subscribing to relevant publications, or engaging in workshops can enhance knowledge and application techniques. Today, innovative solutions are setting new standards across the industry. For instance, hybrid screen technology is integrating the strengths of different screen types to enhance fluid handling capacity while minimizing the risks of screen damage. Continuous learning and adaptation, supported by a wealth of real-world experience, can prepare operators to make informed decisions that optimize drilling operations. In conclusion, the right selection and use of shale shaker screens hinge on a balanced consideration of technical specifications, certification standards, and field experience. Expertise and an authoritative approach are pivotal, rooted in an unwavering commitment to quality and trustworthiness. Adopting these principles will undoubtedly lead to more efficient, effective, and economical drilling operations, underscoring both the art and science that characterize this essential sector of the oil and gas industry.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024