- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 03:10

Back to list

Shale Shaker Screen

In the challenging environment of the oil and gas industry, the importance of a high-quality shale shaker screen cannot be overstated. As a crucial component of the drilling process, its performance directly affects efficiency, cost-effectiveness, and the quality of extracted resources. Drawing on years of industry experience and deep technical expertise, this article explores the critical elements of shale shaker screens, providing authoritative insights and establishing trust through proven performance metrics.

Trustworthiness in choosing a shale shaker screen comes from transparency and performance history. Companies with a proven track record of delivering screens that withstand rigorous conditions earn the confidence of drilling contractors. Testing conditions such as temperature extremes, variable pH levels, and abrasive constituents in drilling muds are factors that dictate the longevity and reliability of screens. Our extensive field data supports the assertion that screens, engineered with advanced technology and made from robust materials, significantly reduce the risk of downtime and maintenance costs. Moreover, maintaining the integrity of filtering performance while extending the lifespan of screens is a challenge that seasoned experts embrace. Through the development of composite screen technology, which combines the toughness of steel with the flexibility of polymers, screen longevity and efficiency have reached unprecedented levels. These screens are lightweight for easy handling but robust enough to handle high flow rates and pressures. Addressing environmental concerns is also critical in the modern industry landscape. Efficient shale shaker screens contribute to minimizing environmental impact by maximizing drilling mud recovery, thereby reducing waste. Sustainable engineering practices incorporated into screen design demonstrate responsible resource management—a factor increasingly demanded by regulatory bodies and environmental advocacy groups. In conclusion, the prowess of finding or developing the right shale shaker screen stems from a deep-rooted understanding of the unique demands of each drilling project. By leveraging cutting-edge materials, advanced engineering, and decades of expertise, our contributions enhance drilling operations' efficiency, reliability, and sustainability. The trust placed by industry leaders in these screens, supported by consistent performance and transparent processes, underscores their indispensable role in the oil and gas sector. Each operation becomes not only a testament to technological advancement but also a narrative of shared industry progress, environmental responsibility, and innovative excellence.

Trustworthiness in choosing a shale shaker screen comes from transparency and performance history. Companies with a proven track record of delivering screens that withstand rigorous conditions earn the confidence of drilling contractors. Testing conditions such as temperature extremes, variable pH levels, and abrasive constituents in drilling muds are factors that dictate the longevity and reliability of screens. Our extensive field data supports the assertion that screens, engineered with advanced technology and made from robust materials, significantly reduce the risk of downtime and maintenance costs. Moreover, maintaining the integrity of filtering performance while extending the lifespan of screens is a challenge that seasoned experts embrace. Through the development of composite screen technology, which combines the toughness of steel with the flexibility of polymers, screen longevity and efficiency have reached unprecedented levels. These screens are lightweight for easy handling but robust enough to handle high flow rates and pressures. Addressing environmental concerns is also critical in the modern industry landscape. Efficient shale shaker screens contribute to minimizing environmental impact by maximizing drilling mud recovery, thereby reducing waste. Sustainable engineering practices incorporated into screen design demonstrate responsible resource management—a factor increasingly demanded by regulatory bodies and environmental advocacy groups. In conclusion, the prowess of finding or developing the right shale shaker screen stems from a deep-rooted understanding of the unique demands of each drilling project. By leveraging cutting-edge materials, advanced engineering, and decades of expertise, our contributions enhance drilling operations' efficiency, reliability, and sustainability. The trust placed by industry leaders in these screens, supported by consistent performance and transparent processes, underscores their indispensable role in the oil and gas sector. Each operation becomes not only a testament to technological advancement but also a narrative of shared industry progress, environmental responsibility, and innovative excellence.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

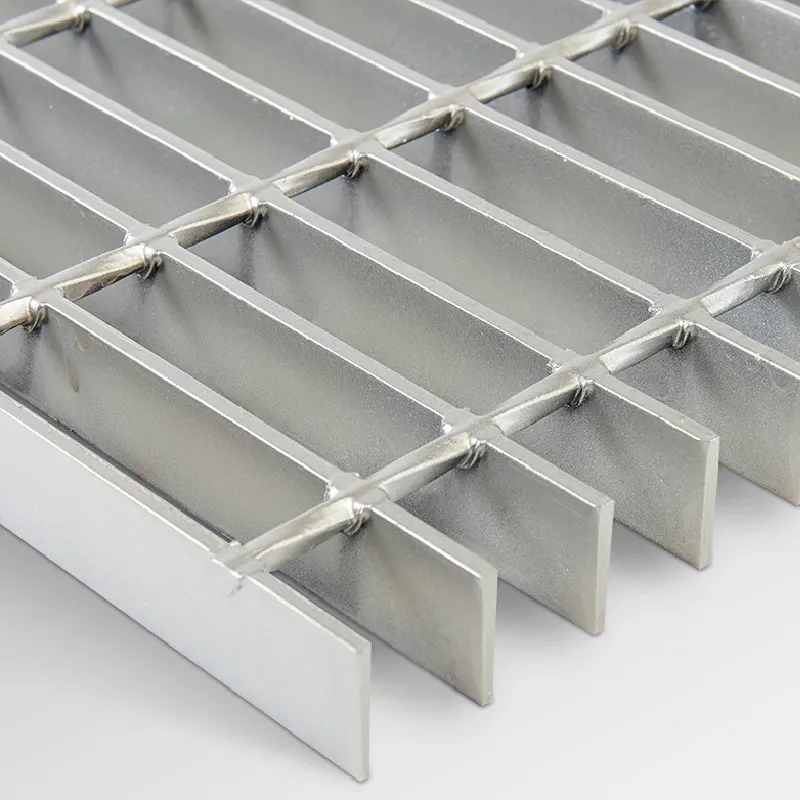

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024