- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 03:41

Back to list

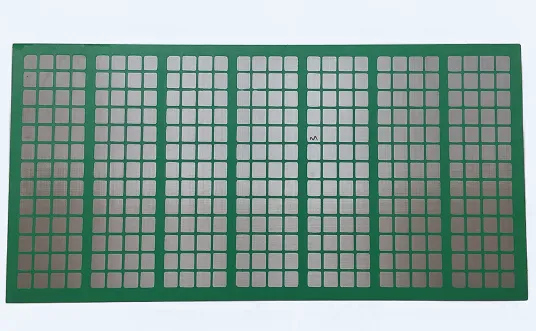

Shale Shaker Screen

Shaker screen mesh, a critical component in the drilling industry, plays an essential role in the separation of solids from drilling fluids. This complex yet indispensable technology requires a thorough understanding to maximize its efficiency and longevity. Through extensive experience and a deep dive into industry specifics, we explore the essential aspects and provide expert insights that can guide those seeking to optimize their operations.

Maintenance is a pivotal aspect ensuring the reliability of shaker screen mesh in the field. Recognizing wear patterns and knowing when to replace screens is essential. Our authoritative advice emphasizes the implementation of regular inspections and proactive replacements to avoid possible operational downtimes and mechanical failures. Through diligent maintenance, the lifespan of shaker screens is maximized, ensuring consistent fluid handling and solids control. It is important to establish trustworthiness in the supply chain of shaker screen meshes. Partnering with reputable manufacturers guarantees the quality and consistency of screen performance. Engaging with industry-verified suppliers, who provide transparent data on product specifications and testing, fosters a trustworthy relationship that promotes reliability and performance assurance. Environmental considerations also play a crucial role. With the current focus on sustainability, modern shaker screen meshes are designed to be more environmentally friendly, minimizing waste and reducing environmental footprints. Our expert recommendation advocates for the adoption of environmentally conscious practices, which not only aligns with global sustainability goals but also enhances corporate reputation. In summary, the intricacies of shaker screen mesh selection and management are pillars of successful drilling operations. By integrating professional expertise with field experience, operations can achieve marked improvements in efficiency, reliability, and sustainability. Through informed decisions on mesh size, material, design, and maintenance, businesses are well-positioned to leverage shaker screen technology to its fullest potential, driving both operational success and environmental stewardship.

Maintenance is a pivotal aspect ensuring the reliability of shaker screen mesh in the field. Recognizing wear patterns and knowing when to replace screens is essential. Our authoritative advice emphasizes the implementation of regular inspections and proactive replacements to avoid possible operational downtimes and mechanical failures. Through diligent maintenance, the lifespan of shaker screens is maximized, ensuring consistent fluid handling and solids control. It is important to establish trustworthiness in the supply chain of shaker screen meshes. Partnering with reputable manufacturers guarantees the quality and consistency of screen performance. Engaging with industry-verified suppliers, who provide transparent data on product specifications and testing, fosters a trustworthy relationship that promotes reliability and performance assurance. Environmental considerations also play a crucial role. With the current focus on sustainability, modern shaker screen meshes are designed to be more environmentally friendly, minimizing waste and reducing environmental footprints. Our expert recommendation advocates for the adoption of environmentally conscious practices, which not only aligns with global sustainability goals but also enhances corporate reputation. In summary, the intricacies of shaker screen mesh selection and management are pillars of successful drilling operations. By integrating professional expertise with field experience, operations can achieve marked improvements in efficiency, reliability, and sustainability. Through informed decisions on mesh size, material, design, and maintenance, businesses are well-positioned to leverage shaker screen technology to its fullest potential, driving both operational success and environmental stewardship.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

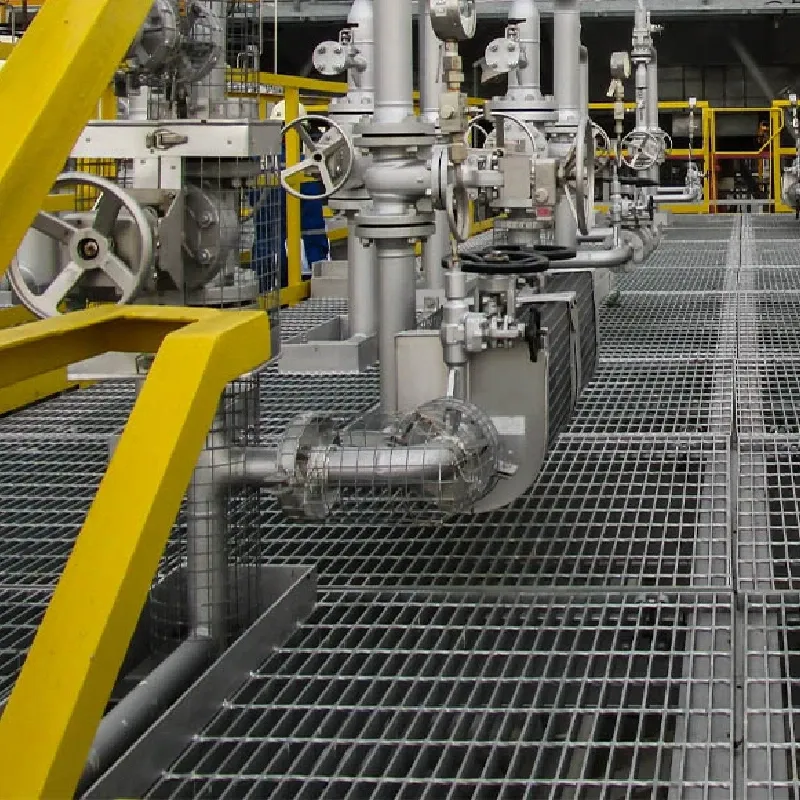

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024