- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 04:12

Back to list

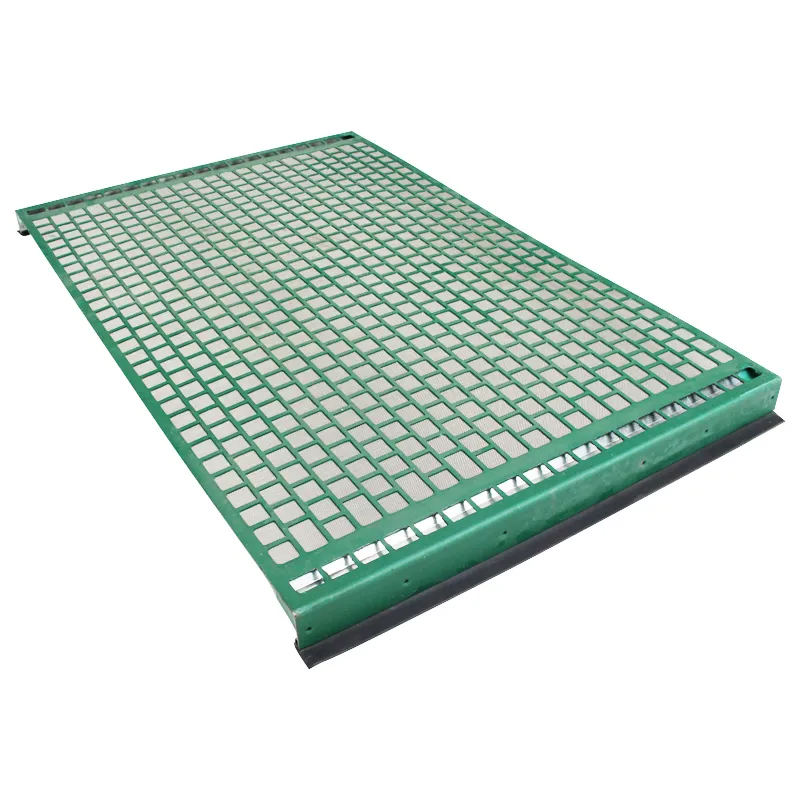

Shale Shaker Screen

The world of shale screens, a pivotal tool in the oil and gas industry, often remains overshadowed by more prominent discussions about shale oil extraction techniques. However, the humble shale screen plays a critical role in ensuring the efficiency and safety of shale oil drilling operations. To truly appreciate their significance, one must delve into the intricacies of their design, application, and the broader impact they have on the industry.

Authority in Manufacturing Choosing the right manufacturer for shale screens is crucial to maintain the high standards required in the industry. Reputable manufacturers are those who not only comply with international standards but also actively invest in research and development. These companies are at the forefront of innovation, consistently improving the materials used, such as stainless steel that resists corrosion, and exploring new technologies like 3D printing for enhanced structural integrity. Trust Built on Performance In the high-stakes environment of oil and gas extraction, trust is earned through consistent performance. Operators prefer shale screens from manufacturers with a proven track record of success. This trust is built over time, through rigorous field-testing and positive client feedback. Testimonials and case studies that showcase real-world applications are invaluable, as they provide tangible proof of a product’s reliability and effectiveness. Future Trends and Sustainability As the industry continues to evolve, so do the technologies associated with shale screens. An emerging trend is the push towards more sustainable practices. This includes developing screens made from recyclable materials and incorporating designs that reduce energy consumption during production. By aligning with these green initiatives, manufacturers not only help reduce the environmental impact but also appeal to eco-conscious operators. Conclusion Investing in high-quality shale screens transcends beyond mere compliance and operational efficiency; it's about securing the future of drilling operations through reliability and innovation. As the industry advances, the emphasis will remain on creating robust, customizable, and environmentally sustainable solutions. Companies that understand and leverage this will lead not just in production efficiency but also in establishing a legacy of trust and authority in the ever-competitive oil and gas landscape.

Authority in Manufacturing Choosing the right manufacturer for shale screens is crucial to maintain the high standards required in the industry. Reputable manufacturers are those who not only comply with international standards but also actively invest in research and development. These companies are at the forefront of innovation, consistently improving the materials used, such as stainless steel that resists corrosion, and exploring new technologies like 3D printing for enhanced structural integrity. Trust Built on Performance In the high-stakes environment of oil and gas extraction, trust is earned through consistent performance. Operators prefer shale screens from manufacturers with a proven track record of success. This trust is built over time, through rigorous field-testing and positive client feedback. Testimonials and case studies that showcase real-world applications are invaluable, as they provide tangible proof of a product’s reliability and effectiveness. Future Trends and Sustainability As the industry continues to evolve, so do the technologies associated with shale screens. An emerging trend is the push towards more sustainable practices. This includes developing screens made from recyclable materials and incorporating designs that reduce energy consumption during production. By aligning with these green initiatives, manufacturers not only help reduce the environmental impact but also appeal to eco-conscious operators. Conclusion Investing in high-quality shale screens transcends beyond mere compliance and operational efficiency; it's about securing the future of drilling operations through reliability and innovation. As the industry advances, the emphasis will remain on creating robust, customizable, and environmentally sustainable solutions. Companies that understand and leverage this will lead not just in production efficiency but also in establishing a legacy of trust and authority in the ever-competitive oil and gas landscape.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024