- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 10:21

Back to list

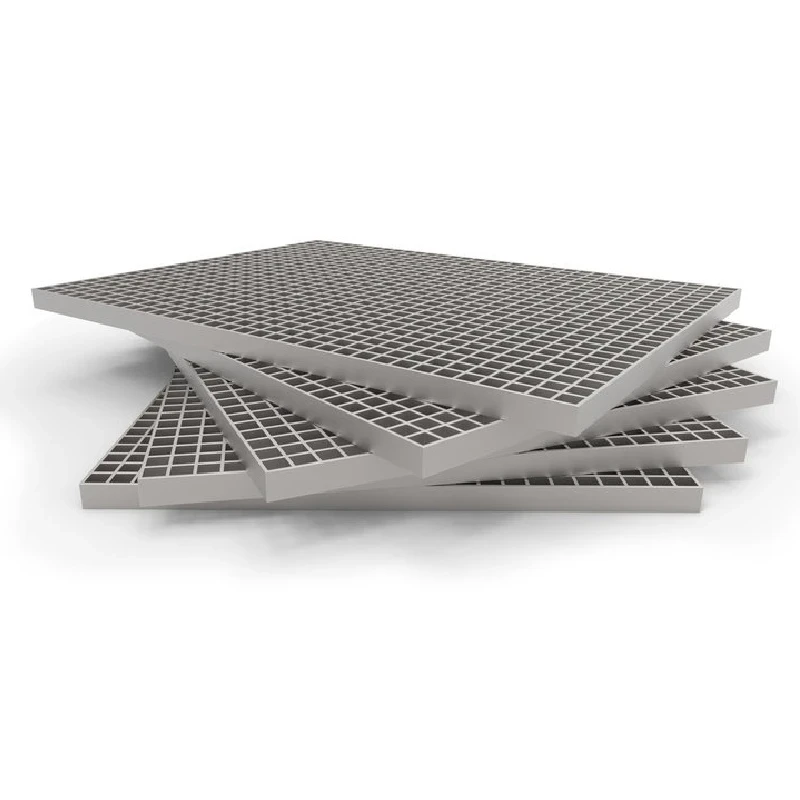

Press-Locked Steel Grating

Understanding the significance of serrated grating and its weight consideration is crucial for industries relying on robust and efficient flooring solutions. Serrated grating stands out due to its unique features, catering to safety, durability, and functionality needs across multiple sectors. When assessing the suitability of serrated gratings, one must delve into the intricate balance between material strength and weight efficiency, a critical factor for ensuring structural stability and operational reliability.

From an engineering perspective, achieving the desired balance between serrated grating's weight and performance involves meticulous analysis. Computational modeling and simulations play a significant role in fine-tuning the design parameters, enabling manufacturers to predict the grating's behavior under various load conditions. This scientific approach ensures that the gratings not only meet industry standards but also exceed them in terms of efficiency and safety. Industry authorities recognize the significance of rigorous testing and certification to establish the credibility of serrated gratings. Independent assessments conducted by organizations assure compliance with international safety and quality standards. These certifications are vital for building trust among consumers, as they guarantee that the products meet the required safety criteria and deliver on their promises. Trustworthiness in serrated grating solutions is also derived from transparent communication and comprehensive customer support provided by manufacturers. End users benefit from easy access to detailed specifications, installation guidelines, and maintenance advice, empowering them to make informed decisions. Manufacturers who prioritize after-sales service demonstrate commitment to customer satisfaction, further cementing their reputation as reliable providers of industrial solutions. In conclusion, serrated gratings represent a synergy of innovation and practicality, essential for industries demanding safety, efficiency, and durability. The meticulous consideration of weight not only serves practical installations but also enhances operational workflows and cost management. By choosing certified and expertly crafted serrated gratings, industries can secure a tangible return on investment through reduced workplace hazards, lower maintenance costs, and extended product lifespan. As technologies evolve, the future of serrated grating design holds promise for even greater advancements in material science and engineering, steering industries towards safer and more efficient operational paradigms.

From an engineering perspective, achieving the desired balance between serrated grating's weight and performance involves meticulous analysis. Computational modeling and simulations play a significant role in fine-tuning the design parameters, enabling manufacturers to predict the grating's behavior under various load conditions. This scientific approach ensures that the gratings not only meet industry standards but also exceed them in terms of efficiency and safety. Industry authorities recognize the significance of rigorous testing and certification to establish the credibility of serrated gratings. Independent assessments conducted by organizations assure compliance with international safety and quality standards. These certifications are vital for building trust among consumers, as they guarantee that the products meet the required safety criteria and deliver on their promises. Trustworthiness in serrated grating solutions is also derived from transparent communication and comprehensive customer support provided by manufacturers. End users benefit from easy access to detailed specifications, installation guidelines, and maintenance advice, empowering them to make informed decisions. Manufacturers who prioritize after-sales service demonstrate commitment to customer satisfaction, further cementing their reputation as reliable providers of industrial solutions. In conclusion, serrated gratings represent a synergy of innovation and practicality, essential for industries demanding safety, efficiency, and durability. The meticulous consideration of weight not only serves practical installations but also enhances operational workflows and cost management. By choosing certified and expertly crafted serrated gratings, industries can secure a tangible return on investment through reduced workplace hazards, lower maintenance costs, and extended product lifespan. As technologies evolve, the future of serrated grating design holds promise for even greater advancements in material science and engineering, steering industries towards safer and more efficient operational paradigms.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024