- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 10:40

Back to list

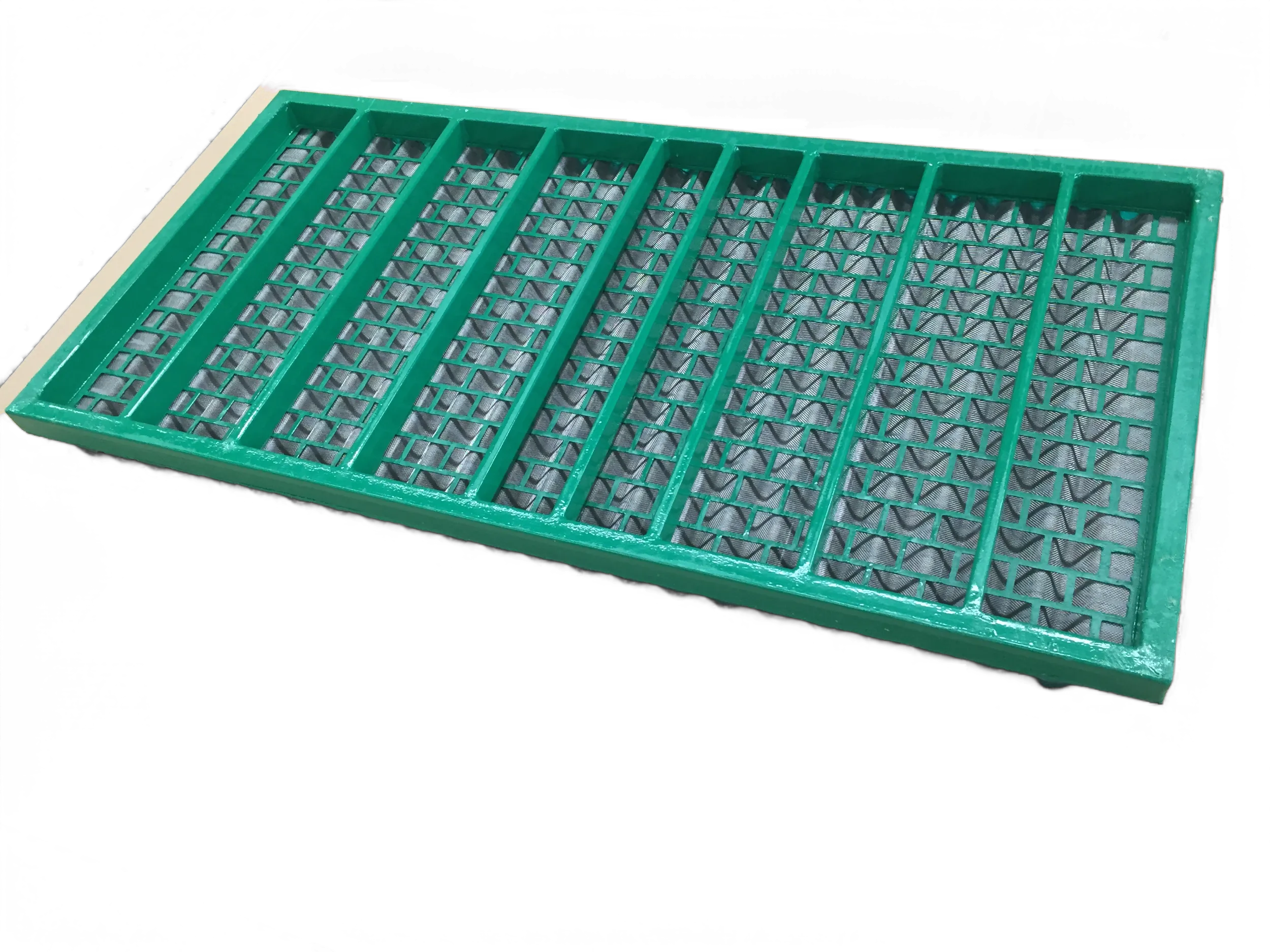

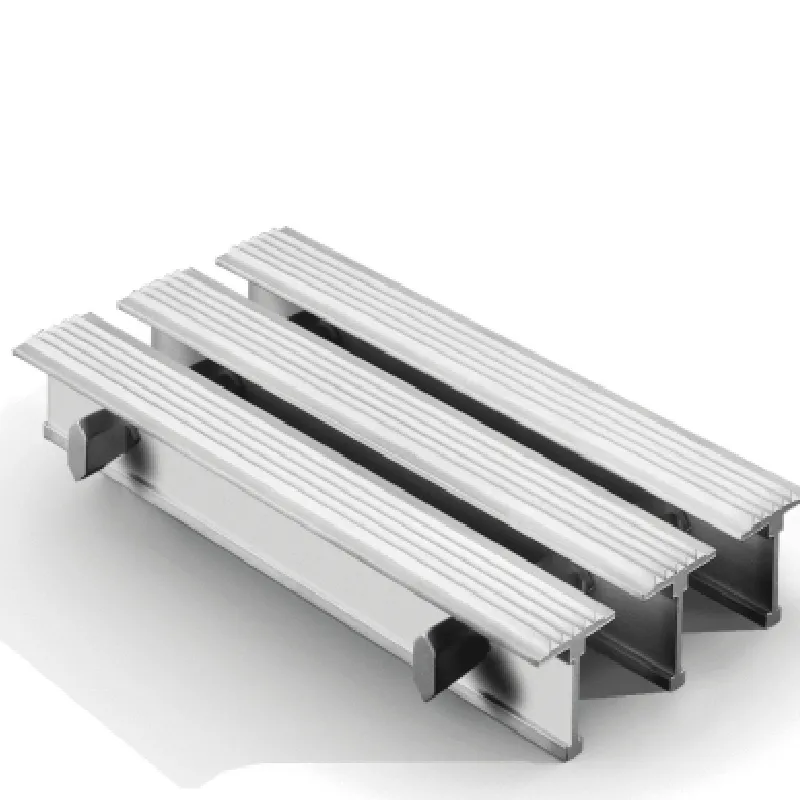

Press-Locked Steel Grating

Serrated metal grating serves as a crucial component across various industries, providing a robust solution to challenges pertaining to safety, durability, and versatility. Valued for its unique design and functional benefits, serrated metal grating has become indispensable in manufacturing facilities, commercial infrastructures, and even in residential projects. This article delves into the multifaceted uses and intrinsic qualities of serrated metal grating, emphasizing its practical applications and contributions to industry standards, while ensuring it is aligned with the search engine optimization guidelines for enhanced visibility online.

Understanding the installation process and maintenance requirements of serrated metal grating underscores its practicality. Typically, installation is straightforward, with panels being cut to size and easily affixed to supporting structures, minimizing labor costs and project timelines. Regular maintenance involves simple cleaning procedures to avoid debris accumulation, ensuring the grating remains effective and visually appealing over time. When procuring serrated metal grating, engaging with reputable manufacturers and suppliers is crucial for guaranteeing authenticity and quality. Industry leaders in the production of metal grating often provide comprehensive warranties and after-sales service, contributing to the overall reliability and credibility of the product. Companies that prioritize customer satisfaction and adhere to international manufacturing standards become preferred partners, offering assurance that the products will perform as expected under specified conditions. For businesses planning to integrate serrated metal grating into their operations, collaborating with experts who have a deep understanding of both technical specifications and practical applications is invaluable. Such expertise not only aids in selecting the appropriate type of grating—considering factors like load-bearing capacity, installation environment, and cost efficiency—but also ensures that the integration process is seamless and strategically beneficial. In conclusion, the strategic use of serrated metal grating across sectors highlights its importance in promoting safety, durability, and design innovation. By aligning with best practices and leveraging the intrinsic qualities of this material, industries can enhance their operational efficiency while paving the way for advancements in both commercial and architectural domains. As this field continues to evolve, prospective users and stakeholders must remain informed about emerging trends and technological developments, ensuring their investments yield maximum returns and sustainable growth.

Understanding the installation process and maintenance requirements of serrated metal grating underscores its practicality. Typically, installation is straightforward, with panels being cut to size and easily affixed to supporting structures, minimizing labor costs and project timelines. Regular maintenance involves simple cleaning procedures to avoid debris accumulation, ensuring the grating remains effective and visually appealing over time. When procuring serrated metal grating, engaging with reputable manufacturers and suppliers is crucial for guaranteeing authenticity and quality. Industry leaders in the production of metal grating often provide comprehensive warranties and after-sales service, contributing to the overall reliability and credibility of the product. Companies that prioritize customer satisfaction and adhere to international manufacturing standards become preferred partners, offering assurance that the products will perform as expected under specified conditions. For businesses planning to integrate serrated metal grating into their operations, collaborating with experts who have a deep understanding of both technical specifications and practical applications is invaluable. Such expertise not only aids in selecting the appropriate type of grating—considering factors like load-bearing capacity, installation environment, and cost efficiency—but also ensures that the integration process is seamless and strategically beneficial. In conclusion, the strategic use of serrated metal grating across sectors highlights its importance in promoting safety, durability, and design innovation. By aligning with best practices and leveraging the intrinsic qualities of this material, industries can enhance their operational efficiency while paving the way for advancements in both commercial and architectural domains. As this field continues to evolve, prospective users and stakeholders must remain informed about emerging trends and technological developments, ensuring their investments yield maximum returns and sustainable growth.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024