- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 10:03

Back to list

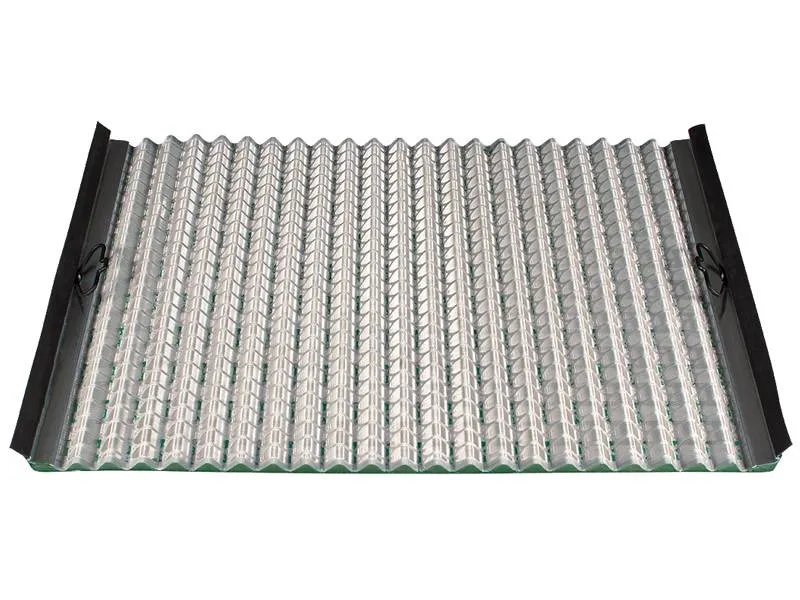

Press-Locked Steel Grating

In the realm of industrial and architectural design, the selection of serrated grating sizes is not merely a technical decision but a pivotal aspect that underscores safety, efficiency, and aesthetic appeal. Serrated gratings, characterized by their jagged, tooth-like surface, are crafted for environments where safety traction capabilities are paramount. As professionals with extensive experience in this domain, we understand the necessity of selecting the correct serrated grating size tailored to specific application needs.

The importance of professional expertise cannot be overstated in the selection process. Poorly chosen grating sizes not only compromise safety but also inflate maintenance costs over time. With over two decades of hands-on experience, we advocate for leveraging expert knowledge to conduct a thorough site assessment and load analysis, which are quintessential for making informed decisions. Continuing advancements in materials science and manufacturing technologies have also expanded the possibilities and applications for serrated gratings. Modern composite materials not only offer reduced weight but also enhanced corrosion resistance, giving them an edge in marine or chemically-exposed environments. These advancements have spurred a shift toward more sustainable and efficient practices, where the long-term benefits of material choice dovetail seamlessly with initial grating size selection. To establish trust in the industry, our guiding principle remains transparency and evidence-backed recommendations. Our clients benefit from exhaustive testing and quality control processes that validate the load-bearing capacities and slip resistance of various grating sizes. By fostering collaborations with top-tier manufacturers and engaging in continuous research, we provide a catalog of serrated grating solutions that set benchmarks in safety and performance standards. In conclusion, the decision-making process around serrated grating sizes is enriched by an understanding of practical requirements and nuanced applications. Engraining expertise and authority in every recommendation, our approach ensures each project achieves both functional excellence and safety compliance. Through meticulous planning and professional insight, we assist our clients in navigating these technical waters, always prioritizing their long-term operational success and safety.

The importance of professional expertise cannot be overstated in the selection process. Poorly chosen grating sizes not only compromise safety but also inflate maintenance costs over time. With over two decades of hands-on experience, we advocate for leveraging expert knowledge to conduct a thorough site assessment and load analysis, which are quintessential for making informed decisions. Continuing advancements in materials science and manufacturing technologies have also expanded the possibilities and applications for serrated gratings. Modern composite materials not only offer reduced weight but also enhanced corrosion resistance, giving them an edge in marine or chemically-exposed environments. These advancements have spurred a shift toward more sustainable and efficient practices, where the long-term benefits of material choice dovetail seamlessly with initial grating size selection. To establish trust in the industry, our guiding principle remains transparency and evidence-backed recommendations. Our clients benefit from exhaustive testing and quality control processes that validate the load-bearing capacities and slip resistance of various grating sizes. By fostering collaborations with top-tier manufacturers and engaging in continuous research, we provide a catalog of serrated grating solutions that set benchmarks in safety and performance standards. In conclusion, the decision-making process around serrated grating sizes is enriched by an understanding of practical requirements and nuanced applications. Engraining expertise and authority in every recommendation, our approach ensures each project achieves both functional excellence and safety compliance. Through meticulous planning and professional insight, we assist our clients in navigating these technical waters, always prioritizing their long-term operational success and safety.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024