- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 15:12

Back to list

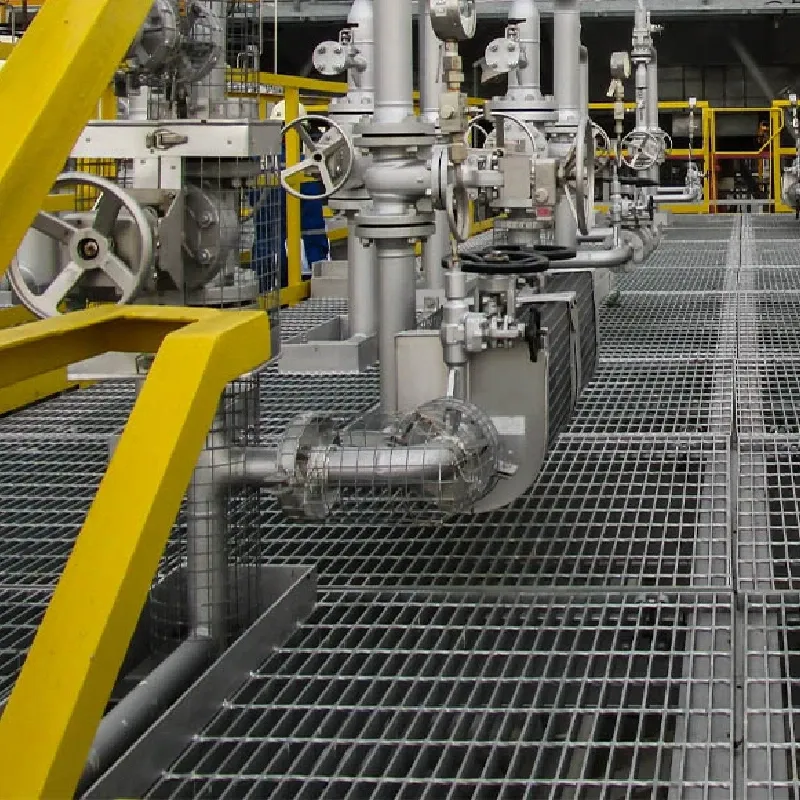

platform grating specification

The contemporary architecture and industrial design landscape often places emphasis on the intricate balance between functionality and aesthetic appeal. Within this framework, platform grating stands out as an indispensable component that effectively marries these two ideals. As businesses and construction projects continue to evolve, understanding the specifications of platform grating becomes paramount to leveraging its full potential.

Coatings and treatments add another layer of complexity and functionality to platform grating. Galvanization remains a popular choice for steel gratings, enhancing corrosion resistance and extending the grating's lifespan significantly. In addition, powder coatings offer an array of color options, not only elevating visual appeal but also enhancing durability, scratch resistance, and, in many cases, anti-slip properties. From an environmental perspective, platform grating exhibits commendable sustainability characteristics. Metal gratings often incorporate a significant percentage of recycled material and can themselves be recycled at the end of their lifecycle, aligning with global sustainability goals. Fiberglass grating, albeit less recyclable, compensates through its longevity and negligible maintenance needs, thus reducing material wastage over time. In the realm of architectural applications, platform grating plays a pivotal role in modern design. Its structural capabilities allow for vast spans and cantilevers, creating spaces that are both open and supportive. The incorporation of platform grating into pedestrian bridges, observation decks, and even urban sculptures testifies to its versatility and aesthetic value. The choice of platform grating should always be aligned with specific project goals and requirements. Collaborating with manufacturers and industry experts can provide invaluable insights into optimizing material, design, and layout for bespoke applications. Such collaborations not only ensure compliance with safety standards but also enhance overall project efficiency and cost-effectiveness. In an era where safety, sustainability, and design are sometimes perceived as conflicting priorities, platform grating emerges as an innovative solution that applauds practicality without forsaking style. As industries progress, the evolution of platform grating specifications—reflecting technological advancements and changing regulatory landscapes—will undeniably continue to influence the way spaces are built and experienced. For stakeholders, understanding its specifications is not merely a matter of product selection, but a crucial decision that can determine the success and sustainability of a project.

Coatings and treatments add another layer of complexity and functionality to platform grating. Galvanization remains a popular choice for steel gratings, enhancing corrosion resistance and extending the grating's lifespan significantly. In addition, powder coatings offer an array of color options, not only elevating visual appeal but also enhancing durability, scratch resistance, and, in many cases, anti-slip properties. From an environmental perspective, platform grating exhibits commendable sustainability characteristics. Metal gratings often incorporate a significant percentage of recycled material and can themselves be recycled at the end of their lifecycle, aligning with global sustainability goals. Fiberglass grating, albeit less recyclable, compensates through its longevity and negligible maintenance needs, thus reducing material wastage over time. In the realm of architectural applications, platform grating plays a pivotal role in modern design. Its structural capabilities allow for vast spans and cantilevers, creating spaces that are both open and supportive. The incorporation of platform grating into pedestrian bridges, observation decks, and even urban sculptures testifies to its versatility and aesthetic value. The choice of platform grating should always be aligned with specific project goals and requirements. Collaborating with manufacturers and industry experts can provide invaluable insights into optimizing material, design, and layout for bespoke applications. Such collaborations not only ensure compliance with safety standards but also enhance overall project efficiency and cost-effectiveness. In an era where safety, sustainability, and design are sometimes perceived as conflicting priorities, platform grating emerges as an innovative solution that applauds practicality without forsaking style. As industries progress, the evolution of platform grating specifications—reflecting technological advancements and changing regulatory landscapes—will undeniably continue to influence the way spaces are built and experienced. For stakeholders, understanding its specifications is not merely a matter of product selection, but a crucial decision that can determine the success and sustainability of a project.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024