- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 14:55

Back to list

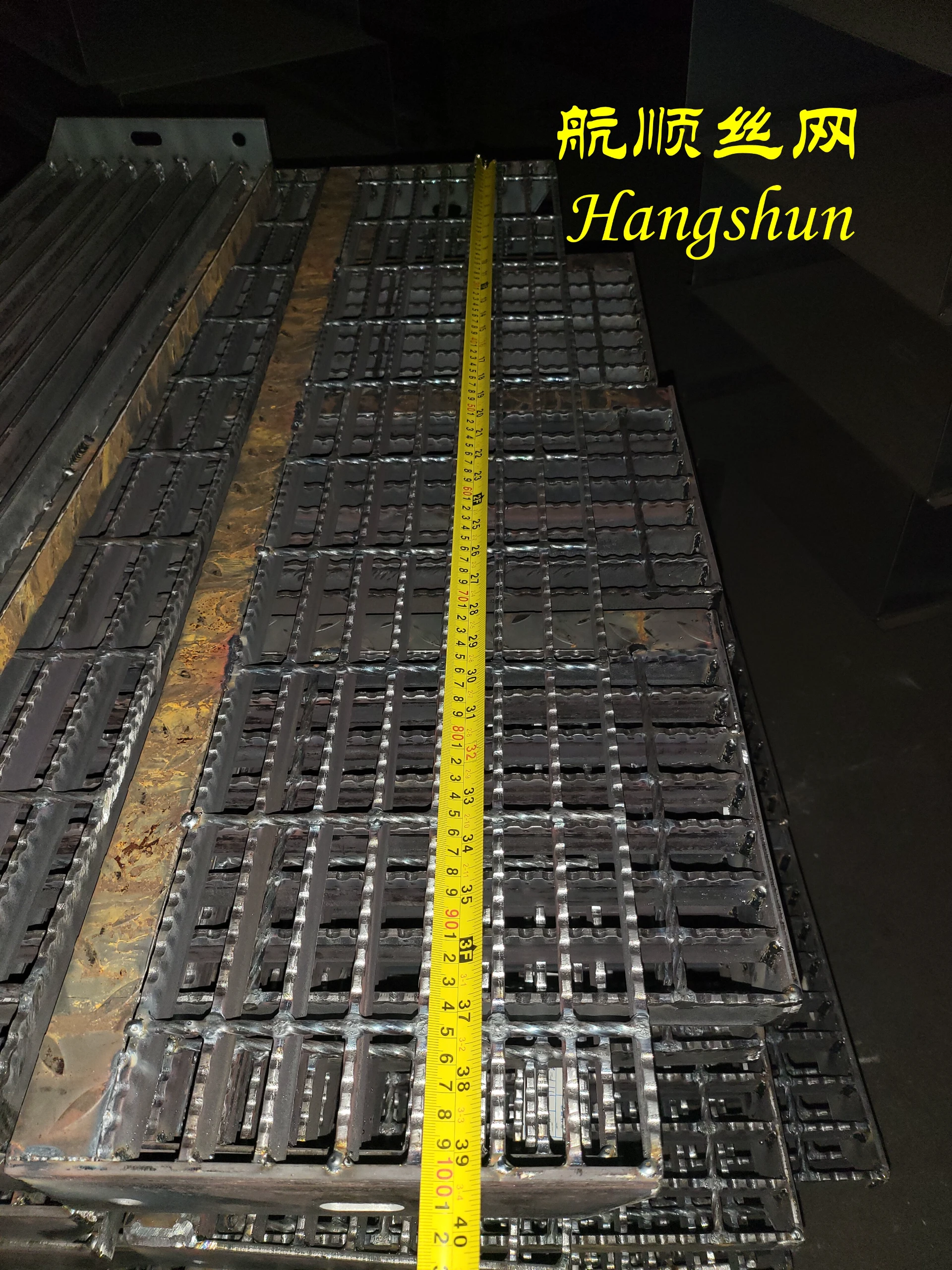

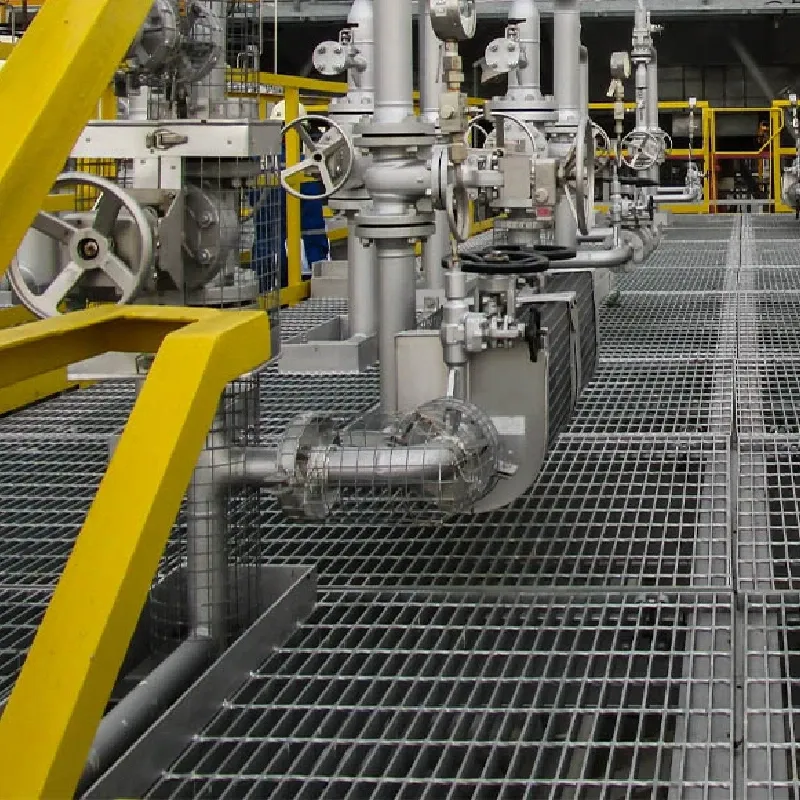

galvanized steel grating platform

Choosing the right platform for industrial and commercial structures is critical in ensuring safety, durability, and efficiency. Galvanized steel grating platforms have emerged as a superior choice for various applications. This article offers an in-depth exploration of galvanized steel grating platforms, focusing on aspects of experience, expertise, authoritativeness, and trustworthiness—touted as the E-E-A-T guidelines by Google itself.

Trustworthiness is another significant concern facility managers and engineers address when selecting construction materials. Reviews and testimonials from industry professionals reveal a strong trust in the performance of galvanized steel gratings. The platforms’ non-slip, open-grid design prevents water accumulation and debris build-up, reducing the risk of accidents and injuries. Moreover, case studies have demonstrated that facilities using these platforms often report fewer incidents compared to those using alternative materials. The carbon footprint is another factor where galvanized steel grating platforms excel. Zinc coating offers extended lifespan and sustainability, as it minimizes the need for replacements and repairs. This aligns well with contemporary environmental considerations, making them an appealing choice for companies aiming to reduce their ecological impact. Various life cycle analyses highlight that galvanized steel can be recycled, continuing the cycle of sustainability. Installation efficiency further exemplifies the benefits of galvanized steel grating platforms, allowing for quick assembly and integration into pre-existing structures. This not only decreases downtime but significantly reduces labor costs and disruption to daily operations, providing an economic advantage alongside functionality. In conclusion, the support of extensive experience, authoritative standards, profound expertise in manufacturing, and a strong reputation for trustworthiness makes galvanized steel grating platforms a compelling option for modern industrial applications. When chosen for the right applications, they provide a blend of durability, safety, and environmental benefits. As industries continue evolving, leveraging materials like galvanized steel grating that adhere to the E-E-A-T principles can be an invaluable decision—not just for the present requirements but as a forward-thinking investment in infrastructure reliability and safety.

Trustworthiness is another significant concern facility managers and engineers address when selecting construction materials. Reviews and testimonials from industry professionals reveal a strong trust in the performance of galvanized steel gratings. The platforms’ non-slip, open-grid design prevents water accumulation and debris build-up, reducing the risk of accidents and injuries. Moreover, case studies have demonstrated that facilities using these platforms often report fewer incidents compared to those using alternative materials. The carbon footprint is another factor where galvanized steel grating platforms excel. Zinc coating offers extended lifespan and sustainability, as it minimizes the need for replacements and repairs. This aligns well with contemporary environmental considerations, making them an appealing choice for companies aiming to reduce their ecological impact. Various life cycle analyses highlight that galvanized steel can be recycled, continuing the cycle of sustainability. Installation efficiency further exemplifies the benefits of galvanized steel grating platforms, allowing for quick assembly and integration into pre-existing structures. This not only decreases downtime but significantly reduces labor costs and disruption to daily operations, providing an economic advantage alongside functionality. In conclusion, the support of extensive experience, authoritative standards, profound expertise in manufacturing, and a strong reputation for trustworthiness makes galvanized steel grating platforms a compelling option for modern industrial applications. When chosen for the right applications, they provide a blend of durability, safety, and environmental benefits. As industries continue evolving, leveraging materials like galvanized steel grating that adhere to the E-E-A-T principles can be an invaluable decision—not just for the present requirements but as a forward-thinking investment in infrastructure reliability and safety.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024