- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 15:30

Back to list

heavy-duty welded bar grating

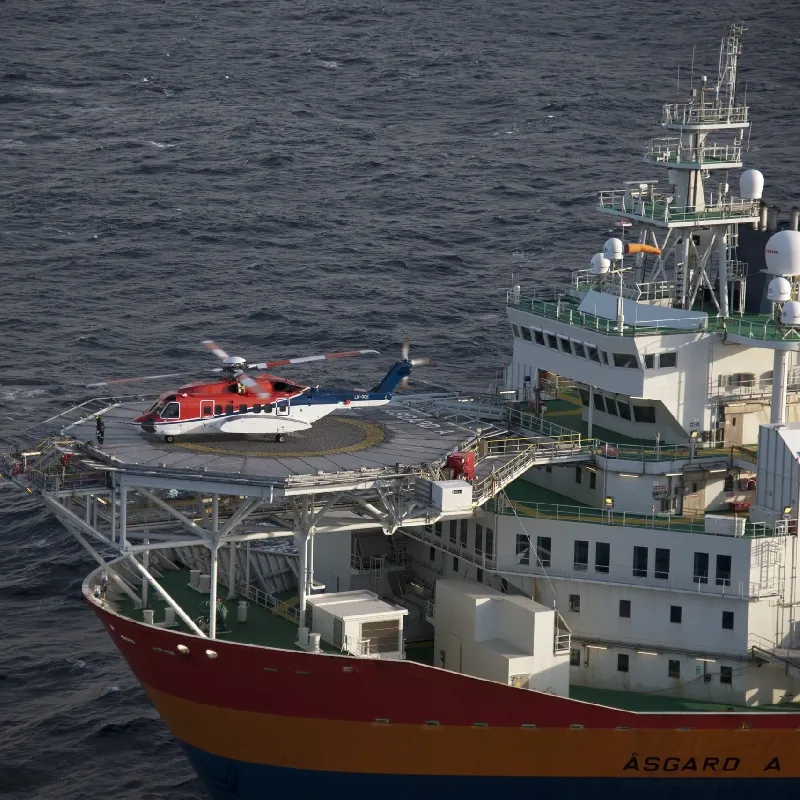

A bar grating platform represents an essential component in various industries, serving as a durable and safe structure for personnel and equipment. To enhance safety, functionality, and longevity, materials such as steel, aluminum, and fiberglass are often selected based on specific environmental and operational conditions.

To ensure user safety and extend the life of these platforms, it is advisable to implement a stringent cleaning schedule. Steel platforms benefit from regular removal of debris and contaminants that can trap moisture and accelerate rusting. Aluminum surfaces, while corrosion-resistant, should still be cleaned to maintain their luster and prevent the buildup of dirt that can lead to staining. For fiberglass, routine cleaning not only maintains their surface integrity but also keeps their non-slip characteristics intact. Bar grating platforms are indispensable, often the backbone that ensures operability in complex industrial environments. Investing in quality materials, diligent maintenance, and timely inspections will maximize their performance and safety. They serve as a testament to engineering ingenuity, bridging practicality with innovation, while underscoring a company's commitment to safety and operational efficiency. Incorporating these platforms into an industrial setup is not just a matter of convenience; it is a strategic decision that can significantly influence productivity, safety, and cost management. Organizations are well-served in consulting with experienced engineers or platform manufacturers to tailor solutions that meet their specific operational and environmental needs. With technological advancements, the options for customized gratings are expanding, offering companies the opportunity to enhance both functionality and aesthetic appeal. A bar grating platform does more than just provide access—it is a reflection of an industry standard that prioritizes durability, efficiency, and safety. As industries evolve, so will the materials and designs of these structures, ensuring they continue to meet the rising demands of modern industrial applications. Maintaining a forward-thinking approach to their integration and upkeep will guarantee that these platforms remain a valuable asset for years to come.

To ensure user safety and extend the life of these platforms, it is advisable to implement a stringent cleaning schedule. Steel platforms benefit from regular removal of debris and contaminants that can trap moisture and accelerate rusting. Aluminum surfaces, while corrosion-resistant, should still be cleaned to maintain their luster and prevent the buildup of dirt that can lead to staining. For fiberglass, routine cleaning not only maintains their surface integrity but also keeps their non-slip characteristics intact. Bar grating platforms are indispensable, often the backbone that ensures operability in complex industrial environments. Investing in quality materials, diligent maintenance, and timely inspections will maximize their performance and safety. They serve as a testament to engineering ingenuity, bridging practicality with innovation, while underscoring a company's commitment to safety and operational efficiency. Incorporating these platforms into an industrial setup is not just a matter of convenience; it is a strategic decision that can significantly influence productivity, safety, and cost management. Organizations are well-served in consulting with experienced engineers or platform manufacturers to tailor solutions that meet their specific operational and environmental needs. With technological advancements, the options for customized gratings are expanding, offering companies the opportunity to enhance both functionality and aesthetic appeal. A bar grating platform does more than just provide access—it is a reflection of an industry standard that prioritizes durability, efficiency, and safety. As industries evolve, so will the materials and designs of these structures, ensuring they continue to meet the rising demands of modern industrial applications. Maintaining a forward-thinking approach to their integration and upkeep will guarantee that these platforms remain a valuable asset for years to come.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024