- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 20, 2025 09:11

Back to list

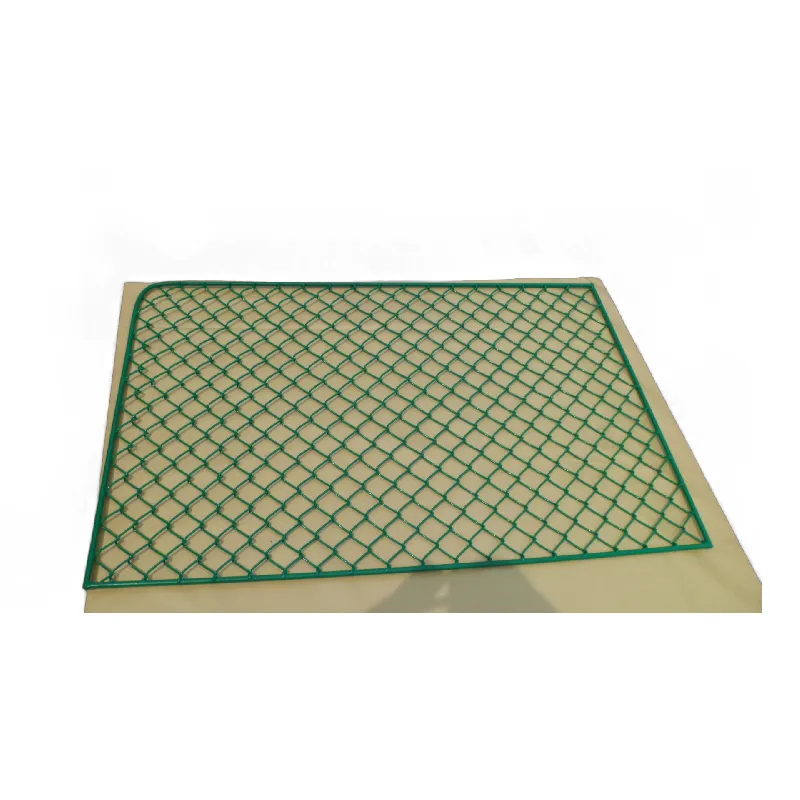

walkway grates

Metal sidewalk grates serve as an indispensable component in urban infrastructure, transforming both functionality and aesthetics of pedestrian pathways. In recent years, these grates have evolved from their simple utilitarian purpose into an essential product that blends safety, environmental compliance, and architectural design. Understanding their significance requires examining the expertise in material selection, engineering precision, and the trust bestowed upon manufacturers by city planners and environmentalists alike.

Trustworthiness is vital in the production and installation of metal sidewalk grates, largely dictated by the manufacturer's reputation and the quality assurance processes in place. Renowned manufacturers often undergo extensive third-party testing and audits to certify their products. Additionally, these companies typically offer warranties and post-installation support, reflecting their confidence in product longevity and performance. These assurances are crucial for city planners and contractors who rely on grates to maintain robust and reliable infrastructure. Furthermore, choosing sustainably sourced materials is becoming increasingly important, reflecting broader environmental awareness. Many manufacturers are now committed to environmentally friendly practices, using recycled metals to manufacture grates, reducing waste, and minimizing their ecological footprint. This not only enhances the sustainability of urban development projects but also aligns with global efforts to combat environmental challenges. Ultimately, metal sidewalk grates are a sophisticated product that encapsulates a blend of technical expertise, compliance with stringent safety standards, and a commitment to sustainable practices. Their role extends beyond mere drainage—these grates are central to creating safe, efficient, and environmentally responsible urban environments. As urban areas continue to expand, the demand for reliable and innovative metal grate solutions is set to rise, underpinning the growth and transformation of cities worldwide. The evolution of metal sidewalk grates epitomizes the future of urban infrastructure, marrying practicality with design, and safety with sustainability.

Trustworthiness is vital in the production and installation of metal sidewalk grates, largely dictated by the manufacturer's reputation and the quality assurance processes in place. Renowned manufacturers often undergo extensive third-party testing and audits to certify their products. Additionally, these companies typically offer warranties and post-installation support, reflecting their confidence in product longevity and performance. These assurances are crucial for city planners and contractors who rely on grates to maintain robust and reliable infrastructure. Furthermore, choosing sustainably sourced materials is becoming increasingly important, reflecting broader environmental awareness. Many manufacturers are now committed to environmentally friendly practices, using recycled metals to manufacture grates, reducing waste, and minimizing their ecological footprint. This not only enhances the sustainability of urban development projects but also aligns with global efforts to combat environmental challenges. Ultimately, metal sidewalk grates are a sophisticated product that encapsulates a blend of technical expertise, compliance with stringent safety standards, and a commitment to sustainable practices. Their role extends beyond mere drainage—these grates are central to creating safe, efficient, and environmentally responsible urban environments. As urban areas continue to expand, the demand for reliable and innovative metal grate solutions is set to rise, underpinning the growth and transformation of cities worldwide. The evolution of metal sidewalk grates epitomizes the future of urban infrastructure, marrying practicality with design, and safety with sustainability.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024