- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 20, 2025 08:42

Back to list

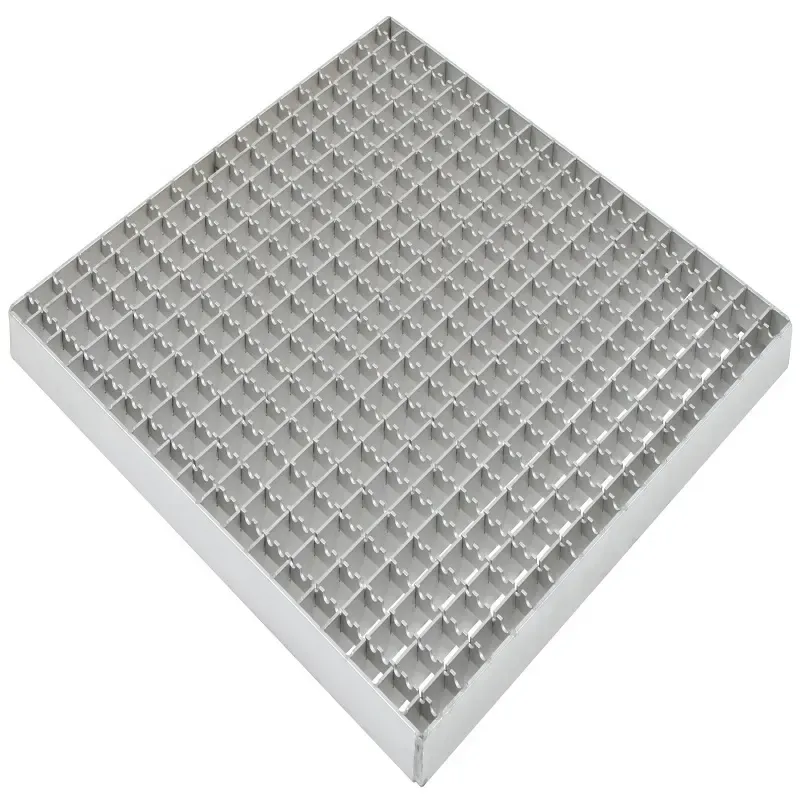

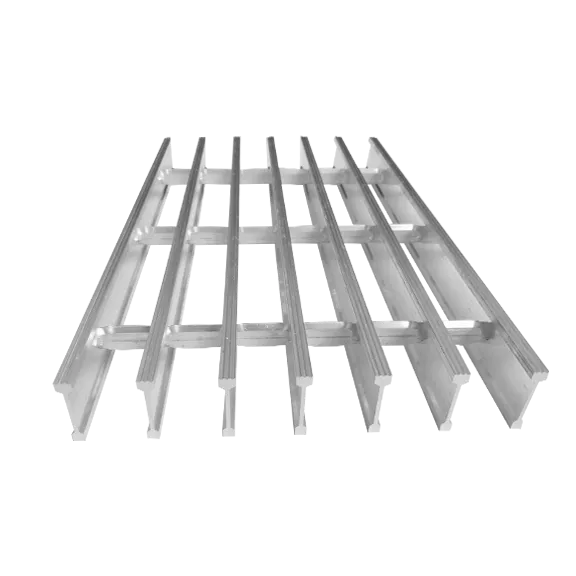

steel walkway grating

Navigating the domain of industrial environments, the essential role of walkway grating becomes profoundly evident. Industrial walkway grating is a crucial component in ensuring safety and functionality across various sectors—from manufacturing plants to oil refineries. As a seasoned industry expert, it is imperative to delve into the nuanced aspects of how these gratings transform industrial spaces while meeting rigorous safety standards.

From an authoritative perspective, adherence to industry standards such as those established by OSHA (Occupational Safety and Health Administration) is non-negotiable. These standards dictate the specific load requirements, spacing, and structural integrity essential for ensuring safe operational environments. Furthermore, ISO certification can also reinforce the credibility and trustworthiness of a grating product in global markets, giving contractors and engineers peace of mind regarding its quality and performance. Industrial walkway grating also requires minimal maintenance, contributing to its cost-effectiveness in the long run. Regular inspection to check for wear, and timely replacement of components can prevent accidents and prolong the lifespan of the walkway system. Such proactive maintenance practices foster a trust-driven environment, reassuring employees and stakeholders of their safety and well-being. Investing in high-quality industrial walkway grating demonstrates foresight and a commitment to safety—a message that resonates well with stakeholders and regulatory bodies alike. In conclusion, industrial walkway grating is not merely a functional component; it is an embodiment of strategic industrial design that fosters safety, efficiency, and longevity. Making informed choices about materials and adherence to standards establishes a legacy of reliability and trust, central to any thriving industrial operation.

From an authoritative perspective, adherence to industry standards such as those established by OSHA (Occupational Safety and Health Administration) is non-negotiable. These standards dictate the specific load requirements, spacing, and structural integrity essential for ensuring safe operational environments. Furthermore, ISO certification can also reinforce the credibility and trustworthiness of a grating product in global markets, giving contractors and engineers peace of mind regarding its quality and performance. Industrial walkway grating also requires minimal maintenance, contributing to its cost-effectiveness in the long run. Regular inspection to check for wear, and timely replacement of components can prevent accidents and prolong the lifespan of the walkway system. Such proactive maintenance practices foster a trust-driven environment, reassuring employees and stakeholders of their safety and well-being. Investing in high-quality industrial walkway grating demonstrates foresight and a commitment to safety—a message that resonates well with stakeholders and regulatory bodies alike. In conclusion, industrial walkway grating is not merely a functional component; it is an embodiment of strategic industrial design that fosters safety, efficiency, and longevity. Making informed choices about materials and adherence to standards establishes a legacy of reliability and trust, central to any thriving industrial operation.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024