- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 09:04

Back to list

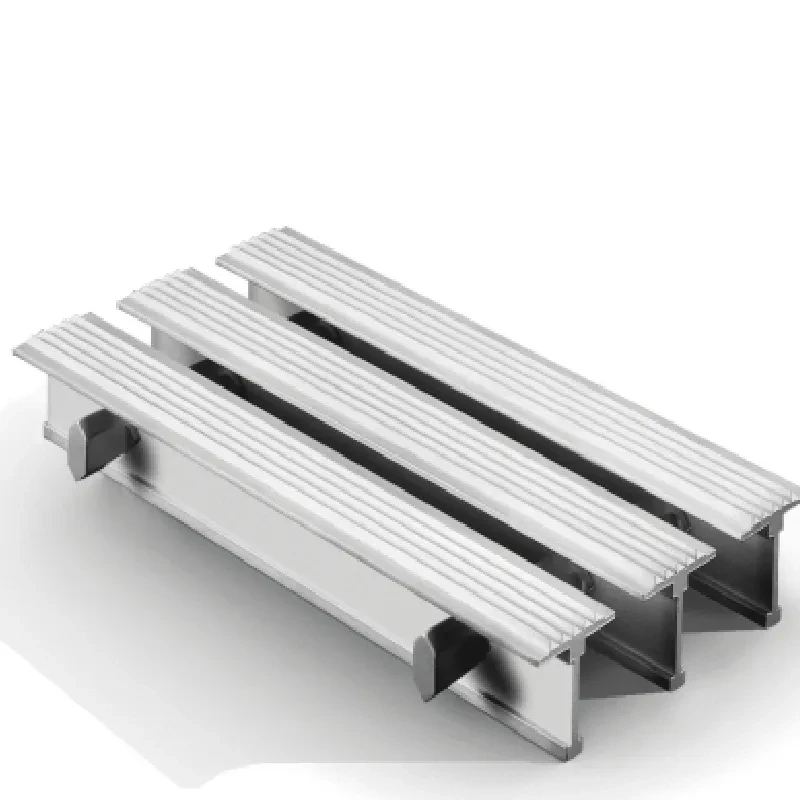

metal grating for sale

When it comes to choosing the right metal grating for your project, understanding the weight implications is crucial. Metal grating, commonly used in industrial, commercial, and infrastructure applications, comes in a variety of materials and specifications to suit different requirements. Knowing the weight of the metal grating can influence installation, maintenance, and overall project cost, making it a key factor in decision-making.

The choice between aluminum, steel, or even fiberglass gratings also ties back to the specific application requirements. Fiberglass gratings, though lighter and resistant to chemicals, often lack the load-bearing capacities of metal options. Hence, for high-load applications, steel remains the preferred choice despite its increased weight. However, in chemical processing environments, fiberglass may be favored due to its natural resistance to corrosion and lower weight. Expertise in selecting the right metal grating requires a thorough analysis of project needs, considering both functional and economic aspects. Gratings must comply with industry standards for safety and performance, and the weight influences load capacities and support structures. Engineers and architects often consult comprehensive product catalogs and weight charts provided by manufacturers to ensure they select the correct grating dimensions and materials. Accurate weight measurement is fundamental not just in transportation and installation, but also in assessing the long-term maintenance of the infrastructure. Heavier gratings might lead to additional pressure on support systems, possibly resulting in more frequent maintenance checks. Lighter gratings, while easier to manage, must not compromise on structural integrity, necessitating a professional balance between these variables. In conclusion, weight is a multifaceted component of metal grating selection that affects not only the operational cost but the structural integrity and sustainability of a project. Whether it's for an industrial plant, a parking deck, or an architectural feature, understanding and optimizing metal grating weight can maximize project success. Consulting with experts and leveraging detailed technical data ensures that each project benefits from the perfect balance of weight, strength, and material properties, aligning with both project goals and budget constraints.

The choice between aluminum, steel, or even fiberglass gratings also ties back to the specific application requirements. Fiberglass gratings, though lighter and resistant to chemicals, often lack the load-bearing capacities of metal options. Hence, for high-load applications, steel remains the preferred choice despite its increased weight. However, in chemical processing environments, fiberglass may be favored due to its natural resistance to corrosion and lower weight. Expertise in selecting the right metal grating requires a thorough analysis of project needs, considering both functional and economic aspects. Gratings must comply with industry standards for safety and performance, and the weight influences load capacities and support structures. Engineers and architects often consult comprehensive product catalogs and weight charts provided by manufacturers to ensure they select the correct grating dimensions and materials. Accurate weight measurement is fundamental not just in transportation and installation, but also in assessing the long-term maintenance of the infrastructure. Heavier gratings might lead to additional pressure on support systems, possibly resulting in more frequent maintenance checks. Lighter gratings, while easier to manage, must not compromise on structural integrity, necessitating a professional balance between these variables. In conclusion, weight is a multifaceted component of metal grating selection that affects not only the operational cost but the structural integrity and sustainability of a project. Whether it's for an industrial plant, a parking deck, or an architectural feature, understanding and optimizing metal grating weight can maximize project success. Consulting with experts and leveraging detailed technical data ensures that each project benefits from the perfect balance of weight, strength, and material properties, aligning with both project goals and budget constraints.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024