- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 09:23

Back to list

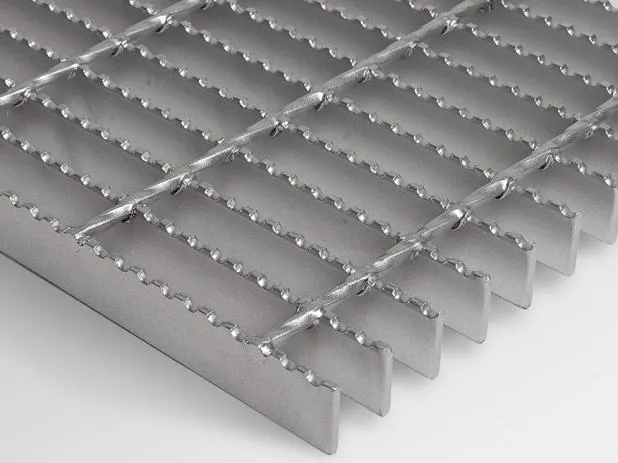

Press-Locked Steel Grating

Non-serrated gratings have emerged as an essential component in various industrial and architectural applications, offering a unique blend of durability, safety, and ease of maintenance. Unlike their serrated counterparts, non-serrated gratings deliver smooth surfaces that are often preferable in environments where aesthetic and easy cleaning are priorities. This article delves into the multifaceted advantages of non-serrated gratings, showcasing their applications and the reasons they might be preferable in specific situations.

A notable advantage of non-serrated gratings is their robustness and longevity. Composed typically of steel, aluminum, or fiberglass, these gratings are engineered to resist corrosion and withstand extreme temperatures, making them suitable for indoor and outdoor applications. The choice of material can be tailored to specific requirements, ensuring that the gratings meet the operational demands while providing cost-effective solutions for extensive installations. When it comes to installation, non-serrated gratings offer simplicity and adaptability. Their modular design allows for quick deployment and customization on-site without extensive labor or specialized equipment. This feature is highly beneficial in situations where time efficiency is critical or where retrofitting onto existing structures is required. The ability to accommodate project adjustments without compromising on structural integrity or performance underscores the practicality of non-serrated gratings. In terms of safety, while serrated gratings are often associated with enhanced grip, the smoothness of non-serrated gratings can also offer sufficient traction when coupled with anti-slip coatings or surface treatments. This adaptability ensures that non-serrated gratings can be safely utilized across various applications without compromising on functionality or safety standards. In conclusion, the decision to use non-serrated gratings should be informed by the specific needs of the project, taking into account factors such as environmental conditions, functional requirements, and aesthetic considerations. With their proven track record of versatility, durability, and low maintenance, non-serrated gratings represent a viable solution for both industrial and architectural applications, providing a balance of form and function that can meet the most stringent demands of modern construction and design. As industries continue to evolve and seek sustainable yet effective solutions, non-serrated gratings will undoubtedly play a significant role in shaping efficient and safe work and public environments.

A notable advantage of non-serrated gratings is their robustness and longevity. Composed typically of steel, aluminum, or fiberglass, these gratings are engineered to resist corrosion and withstand extreme temperatures, making them suitable for indoor and outdoor applications. The choice of material can be tailored to specific requirements, ensuring that the gratings meet the operational demands while providing cost-effective solutions for extensive installations. When it comes to installation, non-serrated gratings offer simplicity and adaptability. Their modular design allows for quick deployment and customization on-site without extensive labor or specialized equipment. This feature is highly beneficial in situations where time efficiency is critical or where retrofitting onto existing structures is required. The ability to accommodate project adjustments without compromising on structural integrity or performance underscores the practicality of non-serrated gratings. In terms of safety, while serrated gratings are often associated with enhanced grip, the smoothness of non-serrated gratings can also offer sufficient traction when coupled with anti-slip coatings or surface treatments. This adaptability ensures that non-serrated gratings can be safely utilized across various applications without compromising on functionality or safety standards. In conclusion, the decision to use non-serrated gratings should be informed by the specific needs of the project, taking into account factors such as environmental conditions, functional requirements, and aesthetic considerations. With their proven track record of versatility, durability, and low maintenance, non-serrated gratings represent a viable solution for both industrial and architectural applications, providing a balance of form and function that can meet the most stringent demands of modern construction and design. As industries continue to evolve and seek sustainable yet effective solutions, non-serrated gratings will undoubtedly play a significant role in shaping efficient and safe work and public environments.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024