- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 08:47

Back to list

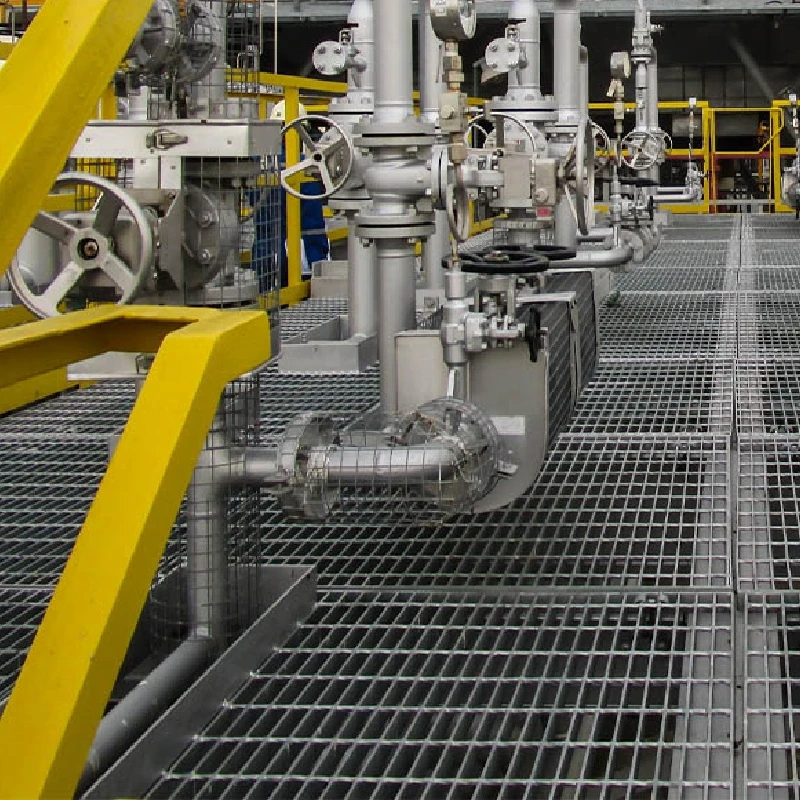

metal grating for sale

Navigating the landscape of metal grating sizes can be a daunting task for both seasoned professionals and newcomers to the industry. With a myriad of sizes and specifications to choose from, making informed decisions is crucial for safety, functionality, and economic efficiency. This article provides a comprehensive guide on metal grating sizes that caters to your specific needs, whether for industrial, architectural, or commercial applications.

Choosing the right grating size depends on several factors, including load requirements, span, durability, and specific application needs. For heavy industrial applications like warehouses and plants, heavier gauge grating such as 30-W-4 may be more appropriate due to its ability to support larger loads. In contrast, lighter grating like 19-W-4 is more suitable for pedestrian traffic and architectural applications due to its optimal balance between strength and space efficiency. Experience reveals that undertaking a load analysis is critical in determining the appropriate grating size. Consult with structural engineers to assess the static (dead) and dynamic (live) loads the grating will support, as these dictate the preferred spacing and size. Moreover, factor in environmental conditions such as exposure to corrosive elements, which could necessitate the use of stainless steel over plain steel for enhanced longevity and safety. Metal grating's versatility also extends beyond standard applications, making custom grating sizes a viable option for niche requirements. Custom sizes ensure that specific operational criteria are met without compromising on performance. Working closely with manufacturers, clients can specify unique bar and cross bar spacing, ensuring the grating meets precise functional and aesthetic needs. In summary, understanding metal grating sizes is essential for optimizing application efficiency and ensuring safety. With the right expertise, selecting an appropriate grating size can vastly improve the lifespan and functionality of your installations. Whether standard or customized, each choice must be informed by careful consideration of load requirements, environmental conditions, and specific application needs. Drawing from practical experience and industry expertise will significantly enhance your procurement process, ensuring that your choice in metal grating serves its intended purpose with utmost reliability and efficiency.

Choosing the right grating size depends on several factors, including load requirements, span, durability, and specific application needs. For heavy industrial applications like warehouses and plants, heavier gauge grating such as 30-W-4 may be more appropriate due to its ability to support larger loads. In contrast, lighter grating like 19-W-4 is more suitable for pedestrian traffic and architectural applications due to its optimal balance between strength and space efficiency. Experience reveals that undertaking a load analysis is critical in determining the appropriate grating size. Consult with structural engineers to assess the static (dead) and dynamic (live) loads the grating will support, as these dictate the preferred spacing and size. Moreover, factor in environmental conditions such as exposure to corrosive elements, which could necessitate the use of stainless steel over plain steel for enhanced longevity and safety. Metal grating's versatility also extends beyond standard applications, making custom grating sizes a viable option for niche requirements. Custom sizes ensure that specific operational criteria are met without compromising on performance. Working closely with manufacturers, clients can specify unique bar and cross bar spacing, ensuring the grating meets precise functional and aesthetic needs. In summary, understanding metal grating sizes is essential for optimizing application efficiency and ensuring safety. With the right expertise, selecting an appropriate grating size can vastly improve the lifespan and functionality of your installations. Whether standard or customized, each choice must be informed by careful consideration of load requirements, environmental conditions, and specific application needs. Drawing from practical experience and industry expertise will significantly enhance your procurement process, ensuring that your choice in metal grating serves its intended purpose with utmost reliability and efficiency.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024