- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 17, 2025 00:54

Back to list

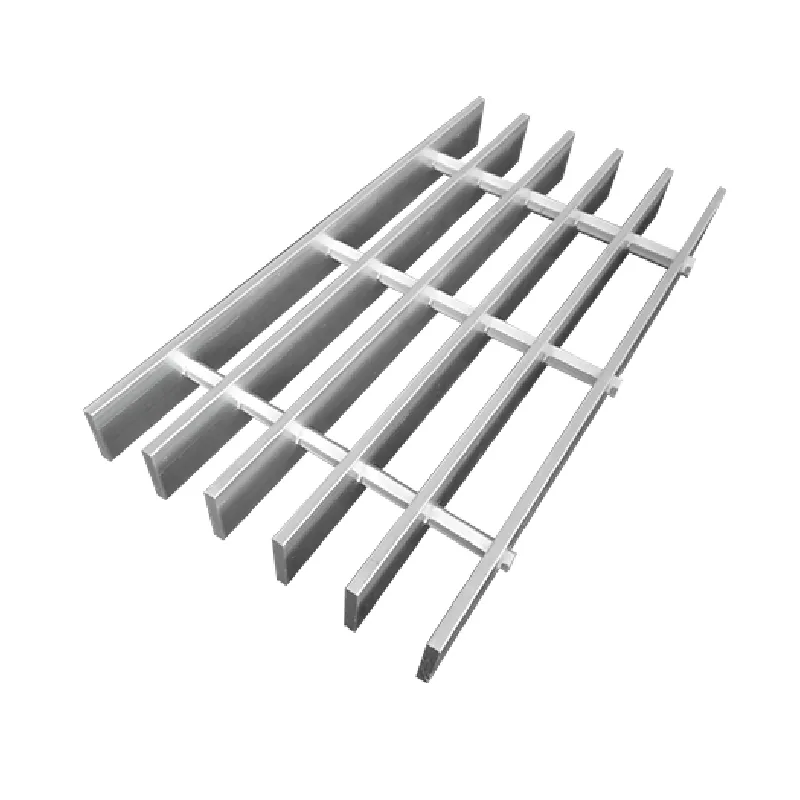

industrial steel grating

Industrial steel grating is a vital component in modern construction and infrastructure projects, renowned for its strength, versatility, and durability. Its application spans across various industries, offering functional and safety benefits that are indispensable for efficient industrial operations.

Authoritativeness in the domain of industrial steel grating is paramount. Leading manufacturers adhere to international standards such as AS/NZS, ANSI, and ISO, guaranteeing that their products not only meet but exceed industry expectations. This compliance ensures that each piece of grating provides the ultimate balance of safety and performance, safeguarding workers and maintaining operational flow within industrial facilities. Trustworthiness is a cornerstone for any supplier in the realm of industrial materials. Established providers offer not just products, but comprehensive support encompassing consultation, design, and installation. Their commitment to quality is reflected in rigorous quality control processes, which include thorough testing to verify load capacity, resistance to corrosion, and structural stability under varied environmental conditions. The evolving landscape of industrial projects necessitates materials that are not only innovative but also sustainable. Steel grating checks this box with its recyclability and reduced environmental impact. Opting for steel grating showcases a commitment to sustainability, as the production of steel has increasingly incorporated environmentally friendly processes. Navigating the selection of industrial steel grating requires an understanding of your project's unique needs. Factors such as load requirements, exposure to corrosive substances, and aesthetic considerations guide the selection process. By leveraging expert advice, stakeholders can navigate these choices effectively, ensuring that every aspect of the grating aligns with their operational goals. In conclusion, industrial steel grating is more than a simple flooring option; it's a strategic investment for industries requiring durability, safety, and efficiency. With an abundance of experience backing their solutions, experts in the field bring a wealth of knowledge that businesses can leverage to enhance their infrastructure robustly and sustainably. Trust, authority, and expertise form the foundation of relationships between manufacturers and clients, ensuring that every project benefits from the finest materials and most informed guidance the industry has to offer.

Authoritativeness in the domain of industrial steel grating is paramount. Leading manufacturers adhere to international standards such as AS/NZS, ANSI, and ISO, guaranteeing that their products not only meet but exceed industry expectations. This compliance ensures that each piece of grating provides the ultimate balance of safety and performance, safeguarding workers and maintaining operational flow within industrial facilities. Trustworthiness is a cornerstone for any supplier in the realm of industrial materials. Established providers offer not just products, but comprehensive support encompassing consultation, design, and installation. Their commitment to quality is reflected in rigorous quality control processes, which include thorough testing to verify load capacity, resistance to corrosion, and structural stability under varied environmental conditions. The evolving landscape of industrial projects necessitates materials that are not only innovative but also sustainable. Steel grating checks this box with its recyclability and reduced environmental impact. Opting for steel grating showcases a commitment to sustainability, as the production of steel has increasingly incorporated environmentally friendly processes. Navigating the selection of industrial steel grating requires an understanding of your project's unique needs. Factors such as load requirements, exposure to corrosive substances, and aesthetic considerations guide the selection process. By leveraging expert advice, stakeholders can navigate these choices effectively, ensuring that every aspect of the grating aligns with their operational goals. In conclusion, industrial steel grating is more than a simple flooring option; it's a strategic investment for industries requiring durability, safety, and efficiency. With an abundance of experience backing their solutions, experts in the field bring a wealth of knowledge that businesses can leverage to enhance their infrastructure robustly and sustainably. Trust, authority, and expertise form the foundation of relationships between manufacturers and clients, ensuring that every project benefits from the finest materials and most informed guidance the industry has to offer.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024