- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 17, 2025 00:33

Back to list

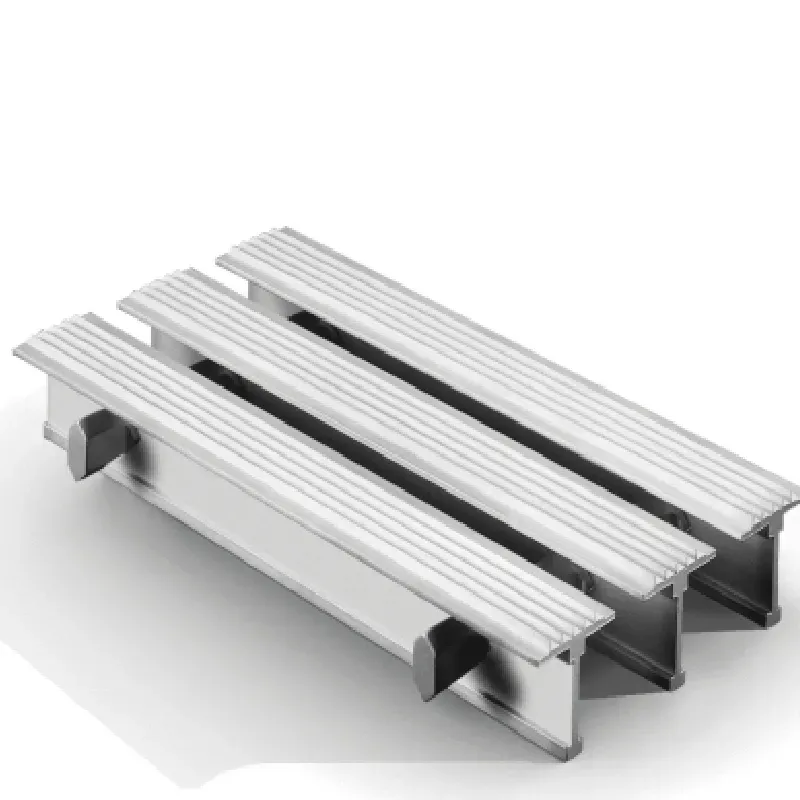

steel grating for drainage

Steel grating for drainage solutions has emerged as a vital component in urban infrastructure, offering not only robust performance but also sustainability and efficiency. Its usage spans numerous applications, from pedestrian walkways in bustling city centers to extensive industrial projects. This innovative material ranks high in resilience and adaptability, making it a preferred choice for engineers and architects alike.

Trust in the safety and performance of steel grating is bolstered by rigorous standards and certifications. Suppliers adhere to stringent industry benchmarks to ensure their products meet or exceed safety requirements. Selecting a certified steel grating not only guarantees longevity but also provides peace of mind to project managers and stakeholders. This focus on standardization plays a critical role in building trust, ensuring that projects are executed with the highest levels of safety and quality. Moreover, real-world experience with steel grating installations underscores its practicality. Case studies from different sectors depict its adaptability across varied climatic and geographical conditions. In regions with severe weather conditions, for example, steel grating drainage systems have effectively mitigated waterlogging, safeguarding infrastructure and enhancing urban life. Similarly, in industrial applications, endurance testing reveals superior wear resistance, even under continuous load stress, affirming its reliability over time. In conclusion, the adoption of steel grating for drainage is not merely a trend but a testament to its unmatched benefits in contemporary infrastructure. Emphasizing experience, expertise, authority, and trustworthiness, this material continues to be an indispensable choice for professionals seeking efficient, durable, and sustainable drainage solutions. Those involved in the specification and procurement of drainage products should consider steel grating as a key element, ensuring that their projects not only meet but exceed performance expectations.

Trust in the safety and performance of steel grating is bolstered by rigorous standards and certifications. Suppliers adhere to stringent industry benchmarks to ensure their products meet or exceed safety requirements. Selecting a certified steel grating not only guarantees longevity but also provides peace of mind to project managers and stakeholders. This focus on standardization plays a critical role in building trust, ensuring that projects are executed with the highest levels of safety and quality. Moreover, real-world experience with steel grating installations underscores its practicality. Case studies from different sectors depict its adaptability across varied climatic and geographical conditions. In regions with severe weather conditions, for example, steel grating drainage systems have effectively mitigated waterlogging, safeguarding infrastructure and enhancing urban life. Similarly, in industrial applications, endurance testing reveals superior wear resistance, even under continuous load stress, affirming its reliability over time. In conclusion, the adoption of steel grating for drainage is not merely a trend but a testament to its unmatched benefits in contemporary infrastructure. Emphasizing experience, expertise, authority, and trustworthiness, this material continues to be an indispensable choice for professionals seeking efficient, durable, and sustainable drainage solutions. Those involved in the specification and procurement of drainage products should consider steel grating as a key element, ensuring that their projects not only meet but exceed performance expectations.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024